Thank you for your

attention on Yesheng !

Exploring ASME SB265 AMS491 ASTM B265 Ti Gr1 Titanium Products: Types and Features

ASME SB265, AMS491, and ASTM B265 standards establish the benchmark for quality and performance in titanium products. Among these, the GR1 titanium alloy stands out for its versatility, corrosion resistance, and lightweight properties. This article delves into various GR1 titanium products, each catering to specific industrial needs, and highlights their distinctive features.

GR1 Titanium Plate

GR1 titanium plates are perhaps one of the most versatile products in the GR1 titanium lineup. These plates, meeting ASTM B265 standards, are widely employed in aerospace, chemical processing, and medical applications. Their exceptional strength-to-weight ratio, corrosion resistance, and formability make them a go-to choice for industries where precision and reliability are non-negotiable.

GR1 Titanium Ingot

The GR1 titanium ingot serves as the foundational material for various downstream products. Produced through a meticulous manufacturing process, these ingots embody the purity and quality required for aerospace, medical, and industrial applications. Their high strength-to-weight ratio makes them an ideal starting point for crafting components where durability and lightness are paramount.

GR1 Titanium Billet

GR1 titanium billets are meticulously crafted cylindrical bars, precision-engineered to meet the highest standards. These titanium billet for sale serve as raw material for further machining, ensuring consistency and integrity in the manufacturing process. Ideal for applications in aerospace engineering, automotive components, and other critical industries, GR1 titanium billets guarantee reliability and performance.

GR1 Titanium Round Rod

GR1 titanium round rods are derived from titanium billets, offering a cylindrical form with a smooth surface finish. These rods find extensive use in various applications, such as marine engineering, chemical processing, and medical equipment manufacturing. The round shape facilitates easy machining and ensures uniformity in the end products.

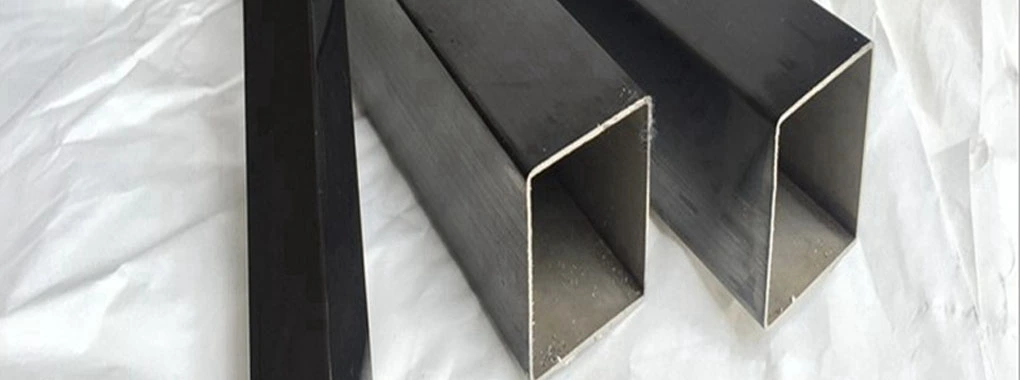

GR1 Titanium Tube

GR1 titanium tubes exemplify the alloy's excellent corrosion resistance and high strength. These tubes find applications in diverse industries, including chemical processing, oil and gas, and medical devices. The seamless tubes, meeting ASME SB265 and ASTM B265 standards, provide an ideal solution for projects demanding durability and resistance to harsh environments.

GR1 Titanium Wire

GR1 titanium wire is a versatile and lightweight material widely used in the aerospace, automotive, and medical sectors. With superior corrosion resistance and high tensile strength, these wires are essential for applications demanding precision and reliability. Whether for surgical implants or intricate components in aviation, GR1 titanium wire ensures exceptional performance.

GR1 Titanium Ball

GR1 titanium balls, precision-engineered to meet stringent specifications, find applications in ball valves, bearings, and other precision instruments. These balls exhibit exceptional corrosion resistance and wear properties, making them an indispensable component in critical machinery across various industries.

GR1 Titanium Powder

GR1 titanium powder opens up new frontiers in additive manufacturing and powder metallurgy. This finely powdered form of titanium is ideal for producing intricate components through processes like powder bed fusion or metal injection molding. The high purity and consistency of GR1 titanium powder, meeting AMS491 standards, ensure optimal results in advanced manufacturing applications with pure titanium powder.

Features of GR1 Titanium Products

Corrosion Resistance: A standout feature across all GR1 titanium products is their exceptional resistance to corrosion. This property makes them invaluable in industries where exposure to corrosive environments is a constant challenge, ensuring longevity and reliability in various applications.

Lightweight: GR1 titanium's low density makes it exceptionally lightweight without compromising strength. This feature is particularly advantageous in aerospace and automotive applications, where reducing overall weight is critical for fuel efficiency and performance.

High Strength: GR1 titanium products boast high tensile strength, allowing them to withstand heavy loads and stresses. This characteristic is crucial in applications where durability and structural integrity are paramount, such as in the aerospace and medical industries.

Biocompatibility: The biocompatibility of GR1 titanium is a key advantage in medical applications, especially for implants and surgical instruments. This property ensures minimal risk of adverse reactions within the human body, making it a preferred material for medical devices.

Conformance to Standards: All GR1 titanium products conform to stringent ASME SB265, AMS491, and ASTM B265 standards. This commitment to quality ensures that these products meet or exceed industry benchmarks, guaranteeing reliability and consistency in various applications.

The ASME SB265 AMS491 ASTM B265 Ti Gr1 titanium product line from Yesheng stands as a testament to innovation and quality in the world of custom titanium products. From ingots to plates, each product type serves a specific purpose, embodying the exceptional features of GR1 titanium, such as corrosion resistance, lightweight construction, and high strength. Whether in aerospace, medical, or industrial applications, the GR1 titanium products from Yesheng titanium factory set a standard for reliability and performance, meeting the stringent requirements of diverse industries.

English

English