Thank you for your

attention on Yesheng !

Anodizing of Titanium Alloys

Anodizing is a process that involves the dissolution of metal at the anode in an electrolyte solution under an applied voltage, forming an oxide layer on the surface. This process is primarily used to enhance surface hardness, wear resistance, corrosion resistance, and the aesthetic appearance of metals. Titanium and titanium alloys are particularly well-suited for anodizing.

I. Applications of Anodizing on Titanium Alloys

(1)Enhancing the Appearance of Titanium Alloy Surfaces

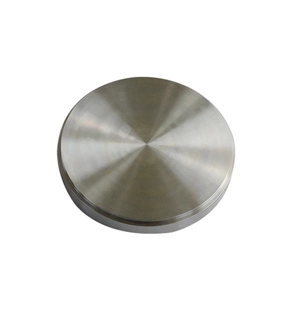

By adjusting the electrolyte composition and process parameters, various colors and finishes can be achieved on the anodized oxide layer. Therefore, anodizing can be applied to improve the surface of titanium alloy products, providing them with better visual appeal, enhanced wear resistance, and increased market competitiveness.

(2)Improving Corrosion Resistance of Titanium Alloy Surfaces

Anodizing also enhances the corrosion resistance of titanium alloys, extending their service life. For instance, in the aerospace industry, anodized titanium alloy components can resist corrosion and aging, ensuring flight safety.

II. Titanium Alloy Anodizing and Coloring Process

(1)Degreasing: First, a strong alkaline degreaser is used to remove any residual rolling oils from the surface of titanium and its alloys. This step is crucial as oil residues can affect the effectiveness of subsequent acid etching and anodizing, potentially leading to uneven coloring.

(2)Initial Acid Etching: After degreasing, an initial acid etching is performed. A 5% by weight solution of hydrofluoric acid is used to etch the titanium and its alloys, helping to create a unique matte finish on the surface.

(3)Secondary Acid Etching: To remove any powdery residues formed during the initial acid etching, a secondary acid etching is necessary. A mixture of hydrofluoric acid and hydrogen peroxide is used to form stable complexes with titanium ions, thus cleaning the surface.

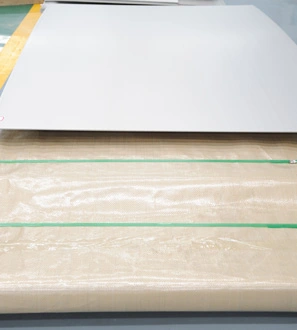

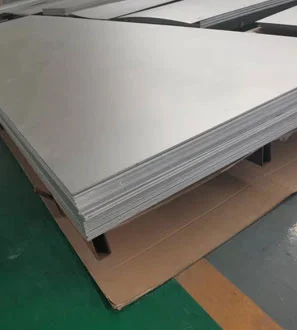

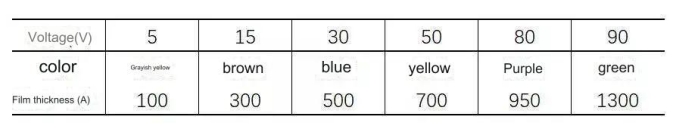

(4)Anodizing: The pre-treated titanium or titanium alloy sheet is used as the anode, and an aluminum sheet as the cathode, in a 1% by weight phosphoric acid electrolyte for constant voltage processing. As the voltage increases, the oxide layer on the titanium surface thickens, exhibiting a variety of colors.

(5)Sealing: To improve the corrosion resistance, stain resistance, and wear resistance of the anodized layer, a sealing treatment is necessary. Common sealing methods include hot water sealing, steam sealing, and solutions containing inorganic salts or organic substances.

(6)Drying: After the sealing process, the surface of the workpiece is wiped with a clean cloth to remove moisture and allowed to air dry.

III. Industrial Applications of Titanium Alloy Anodizing

The anodizing and coloring technology for titanium and its alloys has wide-ranging industrial applications.

Firstly, the process is simple, cost-effective, and suitable for large-scale industrial production.

Secondly, the colored surface of anodized titanium and its alloys offers a rich palette of colors with excellent decorative properties, meeting the aesthetic demands of various fields.

Additionally, the anodized oxide layer provides superior corrosion resistance, stain resistance, and wear resistance, enhancing the lifespan and stability of titanium and its alloys.

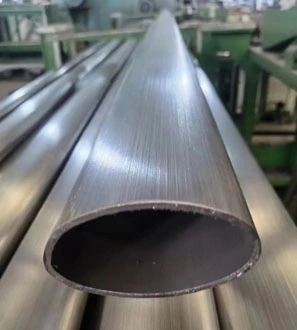

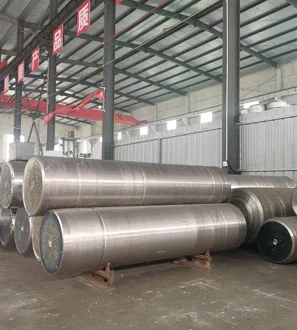

In industrial sectors, this technology can be applied in aerospace, medical devices, architectural decoration, and other fields. For example, in aerospace, anodized titanium alloys can be used to manufacture aircraft components and engine parts; in the medical field, it can be used for surgical instruments and implants; and in architectural decoration, it can be applied to surface treatments of doors, windows, curtain walls, and other building materials.

In conclusion, anodizing and coloring technology for titanium and its alloys holds significant potential and a vast market. As technology advances and industry continues to develop, this technology is expected to see broader applications and promotion in the future.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский