Thank you for your

attention ON YESHENG !

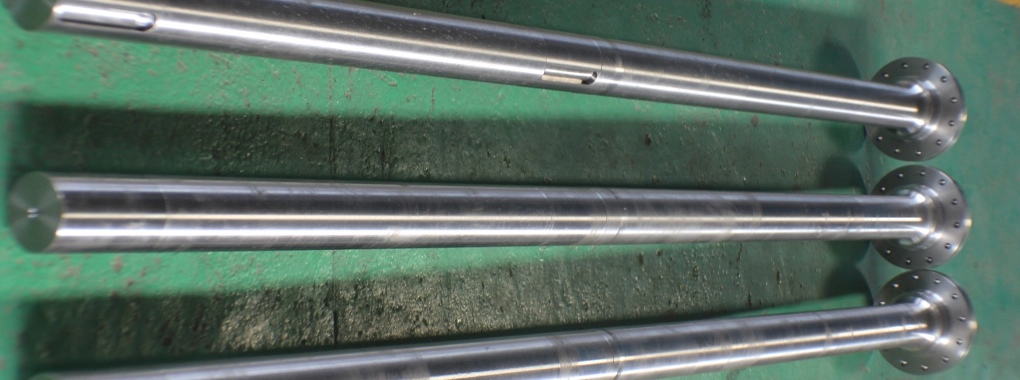

Titanium Shaft Stock for Sale

Engineered for precision and endurance, Yeshengti's Titanium Shafts find applications in aerospace and machinery. These forgings exhibit exceptional strength, fatigue resistance, and corrosion resistance, ensuring smooth and reliable mechanical operations.Contact Yeshengti for more titanium forgings in stock for sale.

Titanium Shaft Specification

| Product Name | Titanium Shaft |

| Grade | GR1,GR2,GR5,GR5ELI,GR7,GR9,GR12,GR23,Ti-4Al-2V,Ti-4Al-1.5Mn. |

| Size | as your request |

| Standard | GB/T16598-1996、GIB2218-1994、GJB2220-1994、GJB2744-1996、GJB391-1987、GJB943-1900、ASTM B381-2005、ASTM F620-2002、AMS4924-2002、AMS4926-2001、AMS4928-2001、AMS4930-2001、AMS4965-2002、AN1S4966-2003、AMS4967-2001、ASM4973-2002、ASM4983-2002、ASN14985-2003、ASM4991-2002、MIL-F-83142-2000 、BS2TA9: 1973、BS2TA13:1974 、BS2TA24:1973 、BSTA42: 1993、BSTA51: 1993、JISH4657-1998、DIN17864-1993、NFL14-602 1984、NFL14-604 1984、NFL14-612 1984 |

| Brand Name | Yesheng |

| Application | chemical industry, Aerospace, deep sea, military, medical, etc. |

| Feature | High corrosion resistance, low density, good thermal stability, High strength and light weight. |

| Technics | Forging Process |

| Surface | Annealed surface, Polished surface. |

| Packing | Export Standard Woodcase |

| MOQ | as your request |

| Payment terms | T/T, Western Union, PayPal. |

| Certificate | ISO 9001:2015; The third test report. |

| Delivery time | 10—25days according to the quantity and process of the product |

| Quality and test | Ingredient testing |

| Price Term: | CIF CNF/CFR FOB Ex-work |

Types of titanium shafts

Titanium shafts are utilized in a variety of sports and recreational equipment, each tailored to specific performance needs:

In lacrosse, titanium shafts like the "Titanium Lacrosse Stick" or "Titanium 7 Lacrosse Shaft" offer lightweight strength, enhancing player agility and durability on the field.

For golf enthusiasts, "Titanium Golf Shafts" or "Titanium Golf Club Shafts" are prized for their superior strength-to-weight ratio, providing increased swing speed and distance.

In dart throwing, "Titanium Dart Shafts" ensure precise control and durability, ideal for competitive play.

Innovative designs like "Titanium Fit Flight Shafts" cater to dart players seeking customizable options for flight and trajectory adjustments.

Specialized applications such as the "Harrison Striper Titanium Shaft" in fishing rods highlight titanium's durability and sensitivity, crucial for anglers.

Whether for lacrosse, golf, darts, or fishing, titanium shafts offer a blend of lightweight performance and robust durability, making them a preferred choice among athletes and enthusiasts seeking superior equipment for competitive and recreational pursuits.

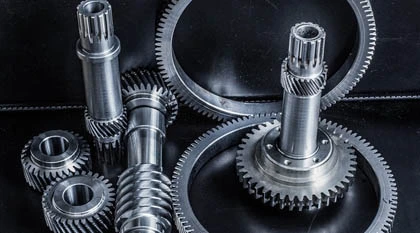

Titanium shaft manufacturing process

Titanium shafts, custom tianium products, are manufactured through several processes, each offering unique benefits:

Machined Shafts: This common method involves CNC machining or lathing solid titanium bars to achieve precise dimensions and features like grooves or threads. It ensures high accuracy and customization capabilities suitable for various sports and industrial applications.

Forged Shafts: Less common but advantageous for certain applications, forging entails shaping titanium under high temperatures and pressure. This process can yield a denser and potentially stronger shaft compared to machined counterparts of the same grade. However, it's less suitable for intricate geometries.

3D Printed Shafts: Emerging technology in titanium shaft manufacturing, 3D printing enables complex near-net-shape parts from titanium powder. This method excels in creating lightweight designs and intricate internal structures within the shaft, optimizing weight and performance. Yet, 3D printed titanium may exhibit slightly different mechanical properties compared to traditionally machined or forged shafts, influencing its application suitability.

The choice of manufacturing process for titanium shafts depends on specific performance requirements, geometrical complexity, and desired mechanical properties for end-use applications.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский