Welding and Joining Techniques of Titanium Bar/Rod

Titanium bar/rod is known for its high strength, low weight, and excellent corrosion resistance, making it essential in manufacturing applications. Welding and joining of titanium bar/rod require specialized techniques, such as gas tungsten arc welding (GTAW), which involves fusing the metal using an electric arc under an inert gas stream. Other methods include laser welding, plasma arc welding and electron beam welding. Joining techniques include fasteners such as screws, nuts, and bolts, and other techniques such as brazing and adhesives. Due to the unique properties of titanium bar/rod, the selection of the appropriate joining technique is essential to achieve maximum performance and longevity.

Advantages of Using Titanium Bar/Rod

1. Lightweight: Titanium is a low-density metal, making it about 50% lighter than steel, which is commonly used in many industries.

2. Corrosion-resistant: Titanium offers excellent resistance to corrosion, making it suitable for use in harsh environments where other metals may corrode or degrade.

3. Strength: Titanium is relatively strong and has an excellent strength-to-weight ratio, making it ideal for high-stress applications.

4. Biocompatible: Titanium is biocompatible, which makes it suitable for use in medical implants and prosthetics.

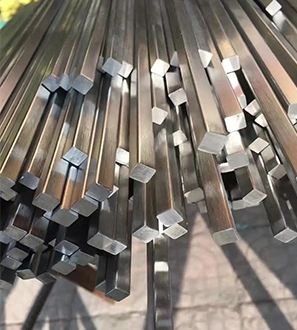

5. Versatility: Titanium bar/rod can be molded into various shapes and sizes, 2mm titanium rod, 3mm titanium rod, 4mm titanium rod, 5mm titanium rod, 6mm titanium rod, 8mm titanium rod, 10mm titanium rod, 12mm titanium rod, 25mm titanium bar, making it suitable for many different applications.

6. Durability: Titanium is highly durable and can withstand significant wear and tear, ensuring it will last for an extended period.

GR5 titanium steel bar and uses

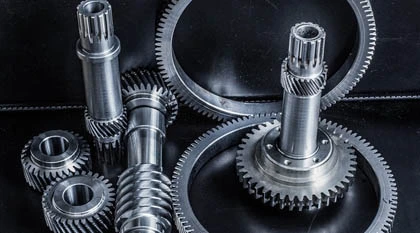

GR5 titanium steel bar finds extensive applications across diverse industries due to its exceptional properties. In the aerospace sector, it plays a crucial role in the manufacturing of engine components, airframe structures, landing gear components, and control surfaces. The high strength-to-weight ratio and corrosion resistance of GR5 titanium steel make it an ideal choice for these critical aircraft parts.

In chemical processing, GR5 titanium steel bar is utilized in the construction of reactors, vessels, pipes, and valves. The material's resistance to corrosion and its ability to withstand harsh chemical environments make it indispensable in ensuring the durability and reliability of these components.

The oil and gas industry benefit from the use of GR5 titanium steel bar in various applications, including drill pipes, casings, wellheads, and manifolds. Its resistance to corrosion from saltwater and hydrocarbons, along with its strength, makes it suitable for enduring the challenging conditions encountered in drilling and extraction operations.

In the medical field, GR5 titanium steel bar serves a critical role in the production of medical implants. This includes hip and knee implants, spinal implants, and dental implants. Its biocompatibility, strength, and durability are essential attributes for ensuring the success and longevity of these implants within the human body.

The military industry relies on the robust nature of GR5 titanium steel bar for applications such as armor plating, helmets, and body armor. Its ability to provide superior strength and protection while remaining lightweight is crucial for enhancing the performance and safety of military equipment.

Moreover, in the automotive sector, GR5 titanium steel bar is employed for high-performance components and exhaust systems. Its strength and heat resistance make it suitable for withstanding the demanding conditions experienced by automotive parts.

Even in consumer goods, GR5 titanium steel bar finds its place in the manufacturing of watches, jewelry, and cookware. Its corrosion resistance, durability, and aesthetic appeal contribute to the production of high-quality and long-lasting consumer products.

The versatility and remarkable properties of GR5 titanium steel bar make it a material of choice across a spectrum of industries, facilitating advancements in technology, medicine, defense, and everyday consumer products.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский