Thank you for your

attention on Yesheng !

How to lead materials science and technology into a new chapter?

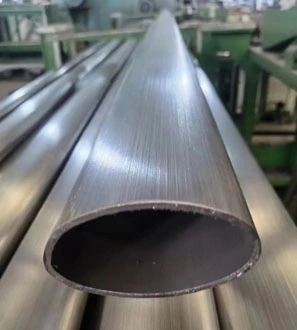

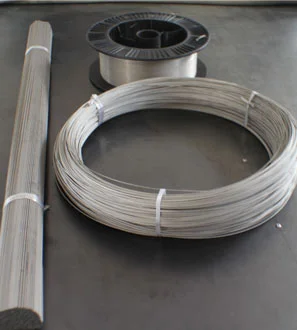

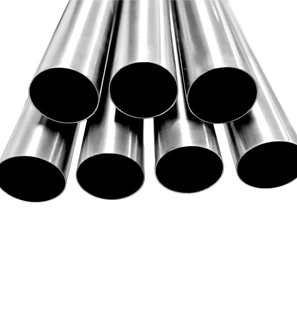

With the continuous progress of material science, new processes for titanium and titanium alloys have become a major highlight in science and technology. These new processes not only enhance the performance of titanium and titanium alloys but also significantly reduce the production cost, opening up a new path for their wide application.

As a rare metal, titanium is relatively abundant in nature, but it has always been regarded as a precious material due to its dispersed existence and difficulty in extraction. With the progress of science and technology, the preparation process of titanium and titanium alloys has been significantly improved. Traditional titanium preparation methods mainly include thermal reduction and molten salt electrolysis. The thermal reduction method utilizes strong reducing agents such as Li, Na, Mg, Ca, etc. to reduce titanium from its compounds at high temperatures, of which the Kroll method and Hunter method are the most widely used methods in the industry. The molten salt electrolysis method, on the other hand, prepares titanium by electrolyzing titanium-containing molten salts and has also made a lot of progress.

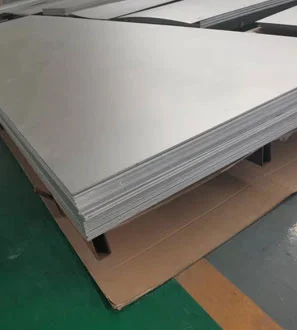

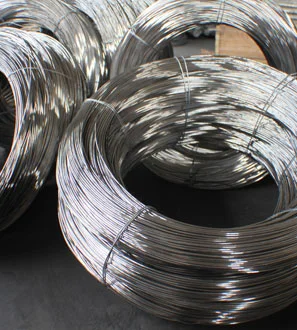

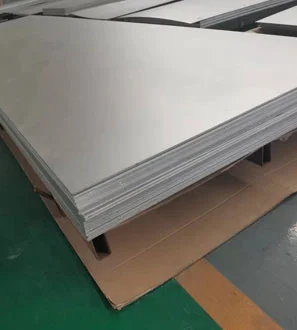

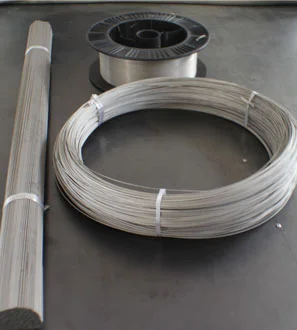

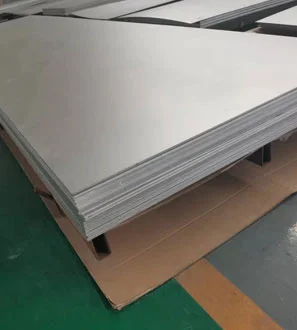

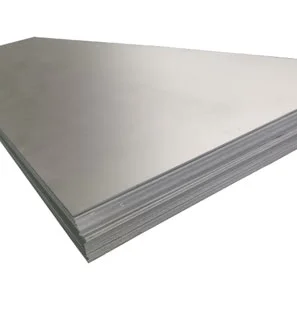

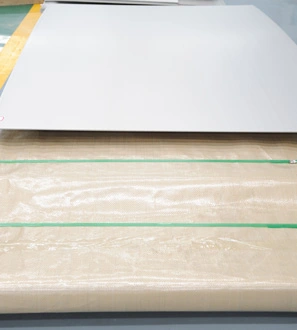

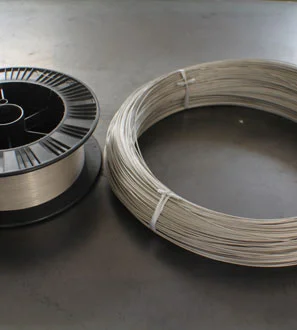

In recent years, new processes for titanium and titanium alloys have emerged. Among them, the powder metallurgy method utilizes titanium powder or titanium alloy powder as raw material, which is molded and sintered to create titanium parts with high performance. The advantage of the powder metallurgy method is that it can prepare titanium products with complex shapes and precise dimensions, and at the same time, it avoids some of the problems in the traditional casting and forging process, such as porosity and inclusions.

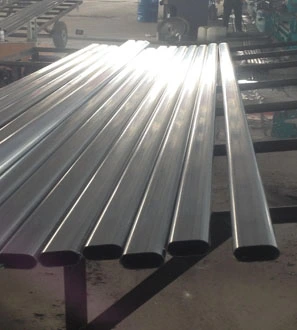

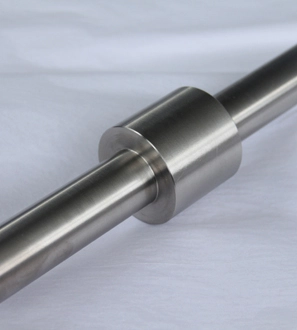

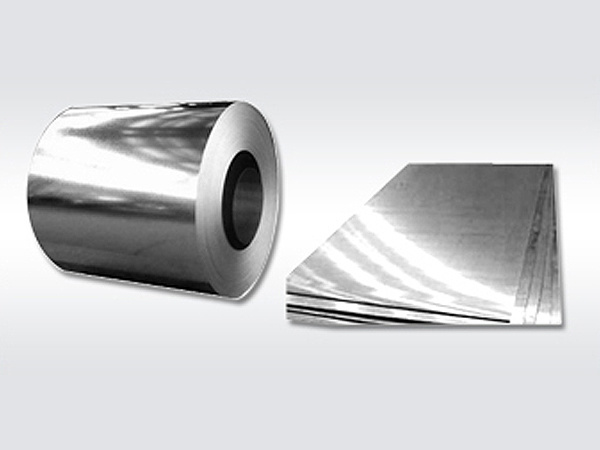

In addition to the powder metallurgy method, near-net molding technology is also a major highlight of the new process of titanium and titanium alloys. Near-net-shape technology includes laser molding, precision casting, precision die forging, spray molding, and other methods, these methods can directly manufacture titanium products close to the final shape and size, greatly reducing the amount of work of subsequent processing. Near-net molding technology not only improves the production efficiency of titanium products but also reduces the cost of production, so that titanium and titanium alloys are in more areas of application.

In terms of titanium alloys, the research and development of new titanium alloys have also made significant progress. University of Science and Technology of Beijing Institute of New Materials Technology has successfully developed a new organizational structure “dense row of hexagonal + face-centered cubic” dual-phase titanium alloy. This titanium alloy not only has the same strength as the current widely used titanium alloy but also shows excellent plasticity, which is twice as much as the traditional titanium alloy. What's more, the preparation cost of this new material is dramatically reduced, thanks to the team's independent invention of low-cost fluidized modified pure titanium powder as the raw material, which reduces the cost by more than 50% compared to traditional raw materials. This innovation not only adds a new member to the titanium alloy material family but also brings new development opportunities for the titanium alloy industry.

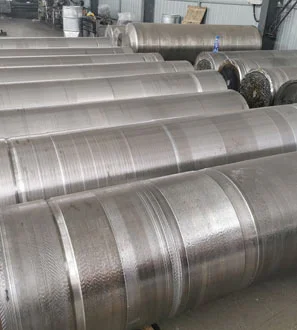

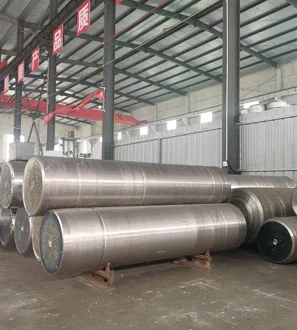

The melting technology of titanium alloy has also been significantly improved. By improving the melting equipment and process parameters, the melting efficiency and product quality of titanium alloy have been significantly improved. At the same time, the casting technology of titanium alloy has also made important breakthroughs, making titanium alloy more widely used in aerospace, military, and other fields.

The new technology of titanium and titanium alloy not only improves the performance of the material but also reduces the production cost, which provides strong support for the wide application of titanium and titanium alloy. With the progress of science and technology and policy support, the titanium and titanium alloy industry will usher in broader development prospects. In the future, we can expect titanium and titanium alloy to show their unique advantages and value in more fields.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский