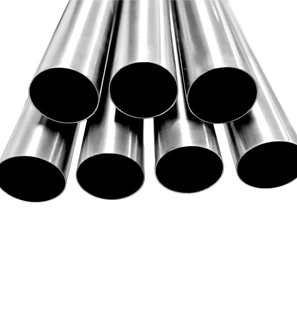

Titanium Tubes for Sale Titanium Tube/Pipe Stock

Titanium tube stock is a type of titanium product that is used across various applications, including the aerospace and medical industries. It is made by melting and casting titanium sponge or scrap, then rolled and welded into tubes. Titanium tubes are known for their high strength, low weight, and excellent corrosion resistance. Inquiry titanium tubes for sale at competitive price.

Types of Titanium Tube for Sale

-

1-inch titanium tube is a versatile piece of metal with unique properties that make it desirable for various applications.Made from titanium, a strong, lightweight metal known for its excellent corros...1 Inch Titanium Tubes Price

1-inch titanium tube is a versatile piece of metal with unique properties that make it desirable for various applications.Made from titanium, a strong, lightweight metal known for its excellent corros...1 Inch Titanium Tubes Price1 Inch Titanium Tubes

-

The 2 Inch Titanium Tubings Stock is a versatile and high-performance inventory item designed for a range of demanding applications.2 Inch Titanium Tubings Price

The 2 Inch Titanium Tubings Stock is a versatile and high-performance inventory item designed for a range of demanding applications.2 Inch Titanium Tubings Price2 Inch Titanium Tubings

-

A 2.5-inch titanium pipe is a robust yet lightweight option for various industrial and performance applications. Due to its unique properties, 2.5-inch titanium pipes find use in various industries.a ...2.5 Inch Titanium Pipes Price

A 2.5-inch titanium pipe is a robust yet lightweight option for various industrial and performance applications. Due to its unique properties, 2.5-inch titanium pipes find use in various industries.a ...2.5 Inch Titanium Pipes Price2.5 Inch Titanium Pipes

-

The 3 inch titanium tubing has a 3-inch outside diameter (OD). Wall thickness can vary depending on the application, with common options ranging from 0.065 inches to thicker for additional strength. ...3 Inch Titanium Pipes Price

The 3 inch titanium tubing has a 3-inch outside diameter (OD). Wall thickness can vary depending on the application, with common options ranging from 0.065 inches to thicker for additional strength. ...3 Inch Titanium Pipes Price3 Inch Titanium Pipes

-

The 3.5 Inch Titanium Tubing Perfect for industries demanding the utmost in durability and resistance, from aerospace to medical.3.5 Inch Titanium Tubing Price

The 3.5 Inch Titanium Tubing Perfect for industries demanding the utmost in durability and resistance, from aerospace to medical.3.5 Inch Titanium Tubing Price3.5 Inch Titanium Tubing

-

The 4 Inch Titanium Pipes is crafted from the highest quality titanium. It is the epitome of strength and resilience. As one of high-quality custom titanium products, it is ideal for a wide range of i...4 Inch Titanium Pipes Price

The 4 Inch Titanium Pipes is crafted from the highest quality titanium. It is the epitome of strength and resilience. As one of high-quality custom titanium products, it is ideal for a wide range of i...4 Inch Titanium Pipes Price4 Inch Titanium Pipes

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский