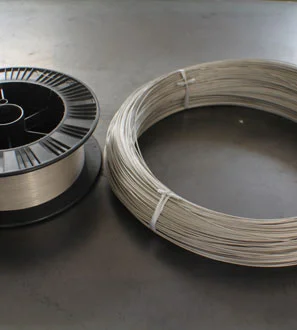

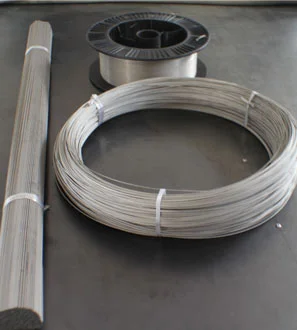

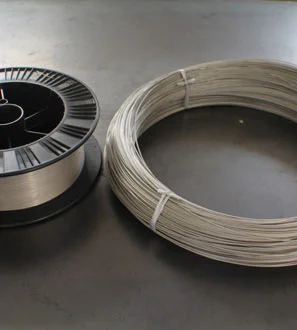

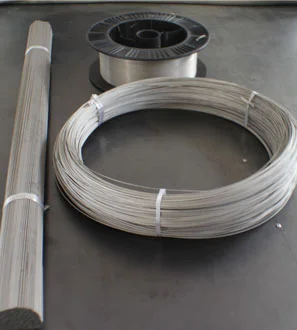

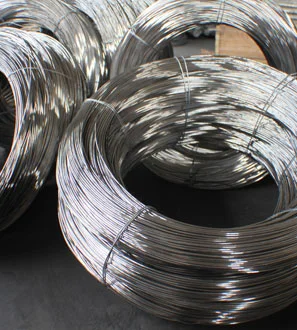

Titanium Wire Titanium Wire Stock

Titanium wire is a highly versatile, corrosion-resistant, and strong wire made from titanium metal. It finds applications in various industries, including aerospace, medical, marine, and automotive, where it is used to make critical components due to its excellent strength-to-weight ratio and biocompatibility.

Titanium Wire Types

-

Gr1 Titanium Wire is a commercially pure titanium wire with excellent corrosion resistance, high strength, and low weight, commonly used in various industrial and medical applications.Gr1 Titanium Wire Price

Gr1 Titanium Wire is a commercially pure titanium wire with excellent corrosion resistance, high strength, and low weight, commonly used in various industrial and medical applications.Gr1 Titanium Wire PriceGr1 Titanium Wire

-

Gr2 Titanium Wire is a commercially pure titanium wire known for its excellent corrosion resistance, formability, and high strength-to-weight ratio, suitable for a wide range of applications.Gr2 Titanium Wire Price

Gr2 Titanium Wire is a commercially pure titanium wire known for its excellent corrosion resistance, formability, and high strength-to-weight ratio, suitable for a wide range of applications.Gr2 Titanium Wire PriceGr2 Titanium Wire

-

Gr3 Titanium Wire is a commercially pure titanium wire with improved corrosion resistance compared to Gr2, commonly used in chemical processing and marine environments.Gr3 Titanium Wire Price

Gr3 Titanium Wire is a commercially pure titanium wire with improved corrosion resistance compared to Gr2, commonly used in chemical processing and marine environments.Gr3 Titanium Wire PriceGr3 Titanium Wire

-

Gr4 Titanium Wire is a commercially pure titanium wire with higher strength and improved corrosion resistance compared to Gr3, suitable for various industrial applications.Gr4 Titanium Wire Price

Gr4 Titanium Wire is a commercially pure titanium wire with higher strength and improved corrosion resistance compared to Gr3, suitable for various industrial applications.Gr4 Titanium Wire PriceGr4 Titanium Wire

-

Gr5 Titanium Wire is a titanium alloy wire made of 6% aluminum and 4% vanadium, known for its high strength, low weight, and exceptional corrosion resistance.Gr5 Titanium Wire Price

Gr5 Titanium Wire is a titanium alloy wire made of 6% aluminum and 4% vanadium, known for its high strength, low weight, and exceptional corrosion resistance.Gr5 Titanium Wire PriceGr5 Titanium Wire

-

Gr5ELI Titanium Wire is a medical-grade titanium alloy wire with the same composition as Gr5, designed for biomedical applications with enhanced biocompatibility properties.Gr5ELI Titanium Wire Price

Gr5ELI Titanium Wire is a medical-grade titanium alloy wire with the same composition as Gr5, designed for biomedical applications with enhanced biocompatibility properties.Gr5ELI Titanium Wire PriceGr5ELI Titanium Wire

-

Gr9 Titanium Wire is a titanium alloy wire with a composition of 3% aluminum and 2.5% vanadium, offering high strength-to-weight ratios and excellent corrosion resistance.Gr9 Titanium Wire Price

Gr9 Titanium Wire is a titanium alloy wire with a composition of 3% aluminum and 2.5% vanadium, offering high strength-to-weight ratios and excellent corrosion resistance.Gr9 Titanium Wire PriceGr9 Titanium Wire

-

Gr23 Titanium Wire is a titanium alloy wire made of 6% aluminum and 4% vanadium, known for its excellent corrosion resistance and high-strength properties.Gr23 Titanium Wire Price

Gr23 Titanium Wire is a titanium alloy wire made of 6% aluminum and 4% vanadium, known for its excellent corrosion resistance and high-strength properties.Gr23 Titanium Wire PriceGr23 Titanium Wire

-

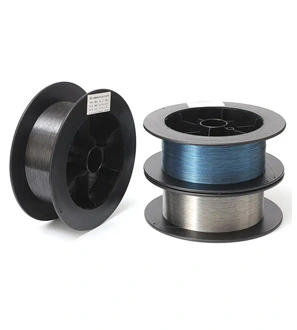

Titanium Weld Wire is a type of wire specifically designed for welding applications using titanium and titanium alloys, providing high-quality and reliable welds.Titanium Weld Wire Price

Titanium Weld Wire is a type of wire specifically designed for welding applications using titanium and titanium alloys, providing high-quality and reliable welds.Titanium Weld Wire PriceTitanium Weld Wire

-

Yeshengti's 14-gauge titanium wire is on sale, providing excellent strength, flexibility, and resistance to corrosion. Perfect for medical, aerospace, and industrial uses, it guarantees dependable...14 Gauge Titanium Wire Price

Yeshengti's 14-gauge titanium wire is on sale, providing excellent strength, flexibility, and resistance to corrosion. Perfect for medical, aerospace, and industrial uses, it guarantees dependable...14 Gauge Titanium Wire Price14 Gauge Titanium Wire

-

Yeshengti's 16-gauge titanium wire is available in Grades 2, 5, and 7. Offering exceptional strength, corrosion resistance, and versatility, it is ideal for aerospace, medical, and industrial appl...16 Gauge Titanium Wire Price

Yeshengti's 16-gauge titanium wire is available in Grades 2, 5, and 7. Offering exceptional strength, corrosion resistance, and versatility, it is ideal for aerospace, medical, and industrial appl...16 Gauge Titanium Wire Price16 Gauge Titanium Wire

-

Yeshengti presents tailor-made 18-gauge titanium wire available for purchase, showcasing superior durability, flexibility, and resistance to corrosion. Perfect for niche uses in aerospace, medical, an...18 Gauge Titanium Wire Price

Yeshengti presents tailor-made 18-gauge titanium wire available for purchase, showcasing superior durability, flexibility, and resistance to corrosion. Perfect for niche uses in aerospace, medical, an...18 Gauge Titanium Wire Price18 Gauge Titanium Wire

-

20 gauge refers to the American Wire Gauge (AWG) system, with lower numbers indicating larger diameters. At 20 gauge, titanium wire is relatively thin and flexible compared to thicker gauges. Titaniu...20 Gauge Titanium Wire Price

20 gauge refers to the American Wire Gauge (AWG) system, with lower numbers indicating larger diameters. At 20 gauge, titanium wire is relatively thin and flexible compared to thicker gauges. Titaniu...20 Gauge Titanium Wire Price20 Gauge Titanium Wire

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский