Thank you for your

attention on Yesheng !

TB6 Titanium Alloy: The Rising Star of High-Strength, High-Toughness Aerospace Materials

TB6 titanium alloy, also known by the American designation Ti-1023, is a high-strength, high-toughness near-β titanium alloy developed in the United States during the 1970s. Its nominal composition is Ti-10V-2Al-3Fe, with aluminum and molybdenum equivalents of 4.0 and 11.1, respectively. The high molybdenum equivalent significantly enhances the alloy's heat treatment strengthening capability. Additionally, the small amount of aluminum not only strengthens the α phase but also inhibits the formation of the ω phase during quenching and aging.

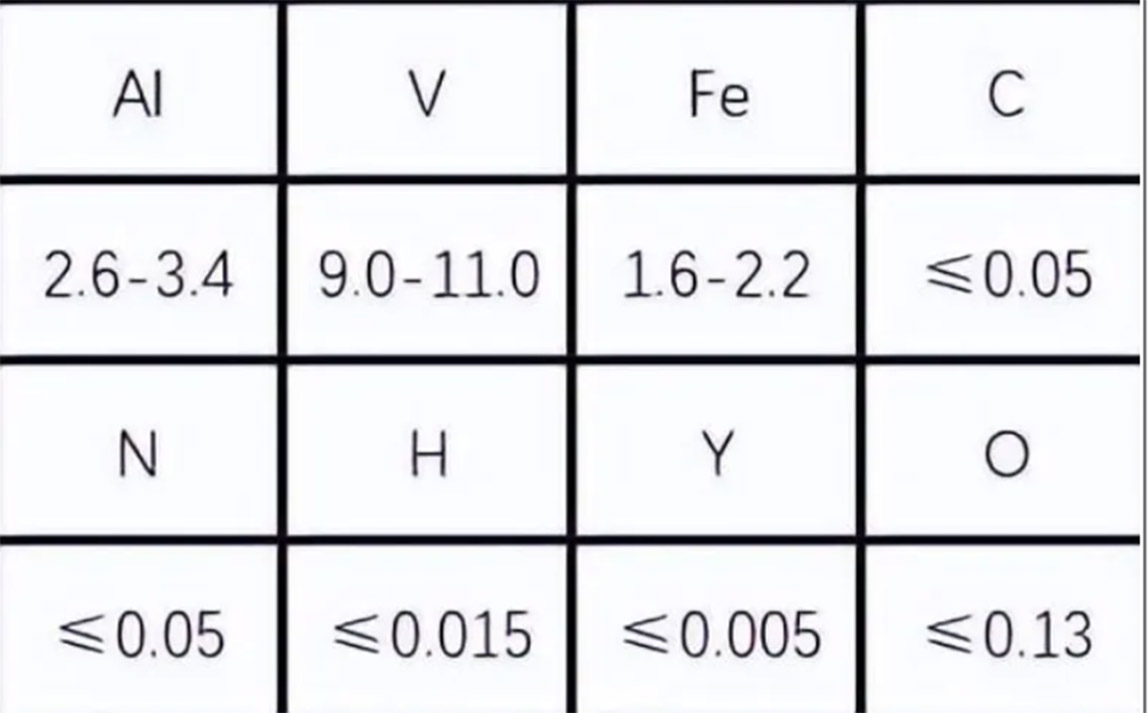

1.Chemical Composition of TB6 Titanium Alloy

2. Properties of TB6 Titanium Alloy

TB6 titanium alloy has a density of 4.62 g/cm³ and a room temperature elastic modulus of 104 GPa. The phase transition temperature is 800°C ± 15°C, and its hardness ranges from 335 to 375 HB. This alloy is renowned for its high specific strength, excellent fracture toughness, lower forging temperature, and strong resistance to stress corrosion. These characteristics make TB6 titanium alloy particularly advantageous in the manufacturing of high-strength titanium forgings. Through heat treatment, TB6 titanium alloy can achieve an ideal balance of strength, plasticity, and toughness over a wide range. Additionally, when used in a solution-treated and aged condition, the maximum hardenability section can reach up to 125 mm.

3. Applications of TB6 Titanium Alloy

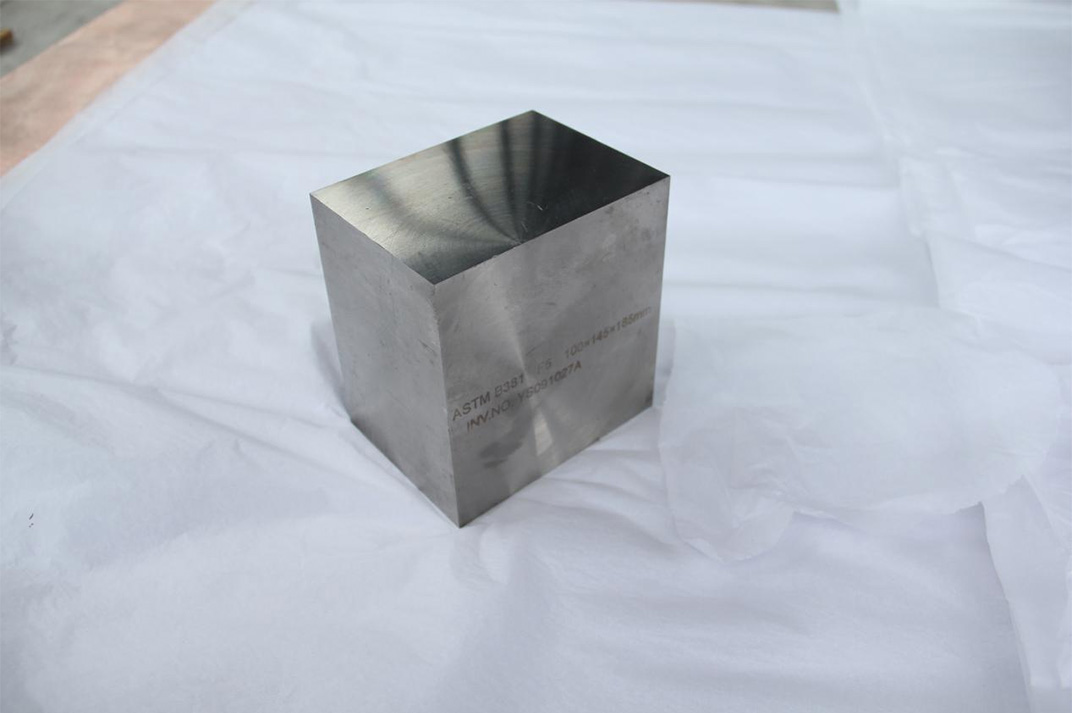

The primary semi-finished forms of TB6 titanium alloy include bars and forgings, but it can also be produced as thick plates and profiles. Due to its exceptional properties, TB6 titanium alloy is particularly suitable for manufacturing isothermal forgings and hot-die forgings. In fact, TB6 alloy has been widely used in various civil and military aircraft, such as the Boeing 757, A320, B-1B, and Mirage 2000. Additionally, TB6 titanium alloy is extensively used in new aircraft like the Boeing 777 and the Super Puma multi-purpose helicopter, contributing significantly to the advancement of the aerospace industry.

Baoji Yesheng Titanium Industry Co., Ltd. is a high-tech company that integrates the production, processing, and sales of titanium and titanium alloys, nickel, zirconium, and other non-ferrous elements. It is situated in China's "Titanium Valley"-Baoji.Plates, bars, wires, tubes, standard components, forgings, equipment, and titanium and titanium alloys are the primary products. Nickel, zirconium, and alloys are also important.Welcome your consultation.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский