Thank you for your

attention on Yesheng !

TC4 Titanium Alloy: An Outstanding Choice for Engineering Applications

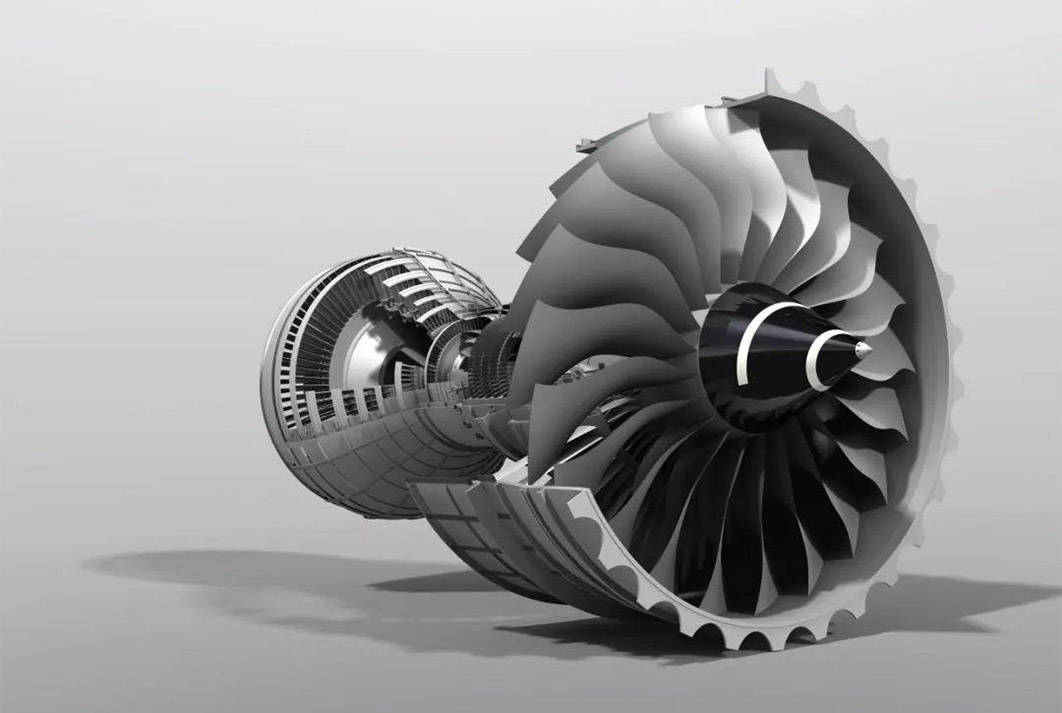

TC4 titanium alloy is a key material in modern engineering fields, renowned for its unique physical and mechanical properties. It plays a significant role in industries such as aerospace, automotive manufacturing, and medical devices. This article will explore the density, mechanical properties, thermal-physical properties, chemical stability, and manufacturing characteristics of TC4 titanium alloy, highlighting its exceptional value in various applications.

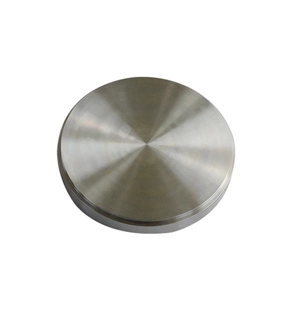

TC4 titanium alloy Density Characteristics

The density of TC4 titanium alloy is approximately 4.4 g/cm³. This characteristic makes it an important material in modern engineering design that prioritizes lightweight structures. Density, which measures the mass per unit volume of a material, directly affects the material's weight and volume. The low-density property of TC4 titanium alloy makes it widely used in the aerospace industry, helping to reduce the overall weight of aircraft and improve flight performance.

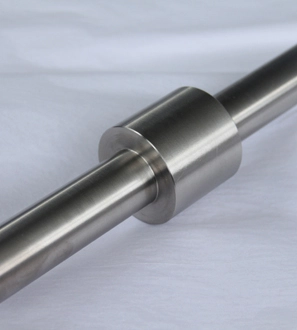

TC4 titanium alloy Mechanical Properties

TC4 titanium alloy exhibits excellent mechanical properties. It has a tensile strength exceeding 1000 MPa and a hardness of around HB 300, coupled with good toughness. These properties allow TC4 titanium alloy to maintain stability and durability even under extreme conditions of high temperature and high pressure, providing reliable material support for complex engineering applications in aerospace, automotive manufacturing, and other fields.

TC4 titanium alloy Thermal-Physical Properties

The thermal conductivity of TC4 titanium alloy is relatively low, about 6.7 W/(m·K). This property allows it to effectively maintain temperature stability in high-temperature environments. Additionally, its coefficient of thermal expansion is approximately 8.6 × 10^-6 /K, indicating that the material is less likely to experience significant deformation or stress concentration with temperature changes. These thermal-physical properties give TC4 titanium alloy a significant advantage in high-temperature engineering applications.

TC4 titanium alloy Chemical Stability

TC4 titanium alloy has excellent corrosion resistance and can withstand oxidation and exposure to acidic and alkaline environments. Even under conditions of high temperature and high pressure, TC4 titanium alloy maintains its structural integrity and stability. This property makes it widely used in marine engineering, chemical equipment, and other fields where resistance to corrosion is critical.

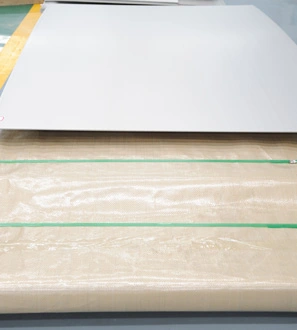

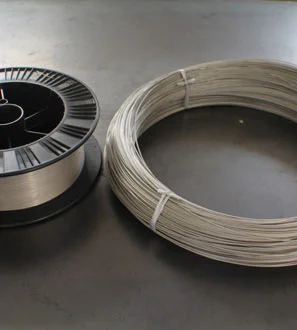

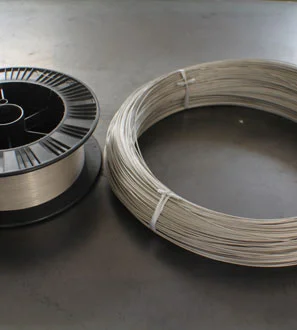

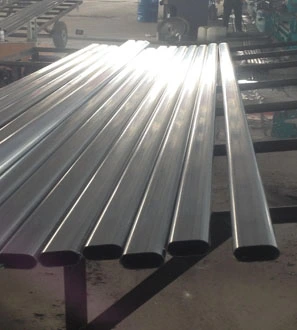

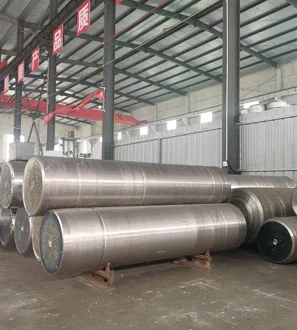

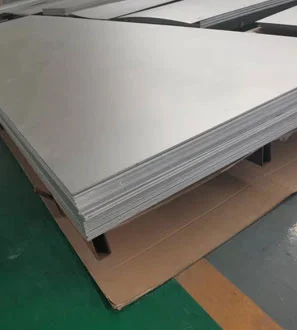

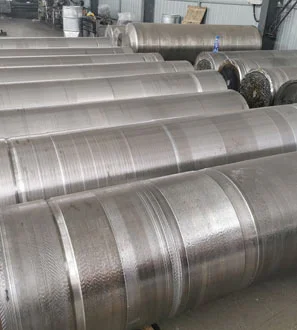

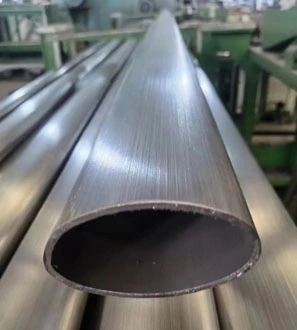

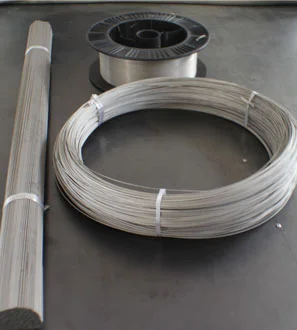

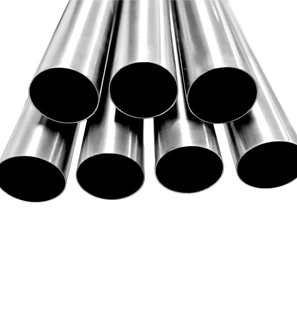

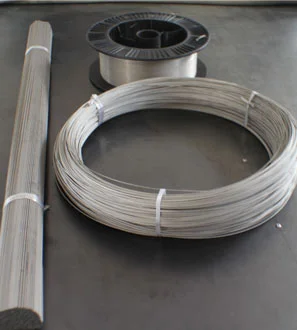

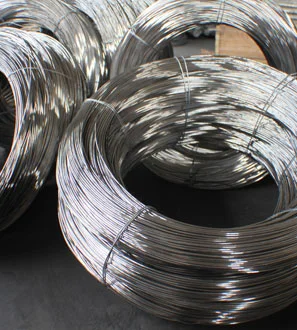

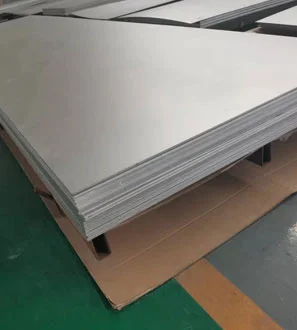

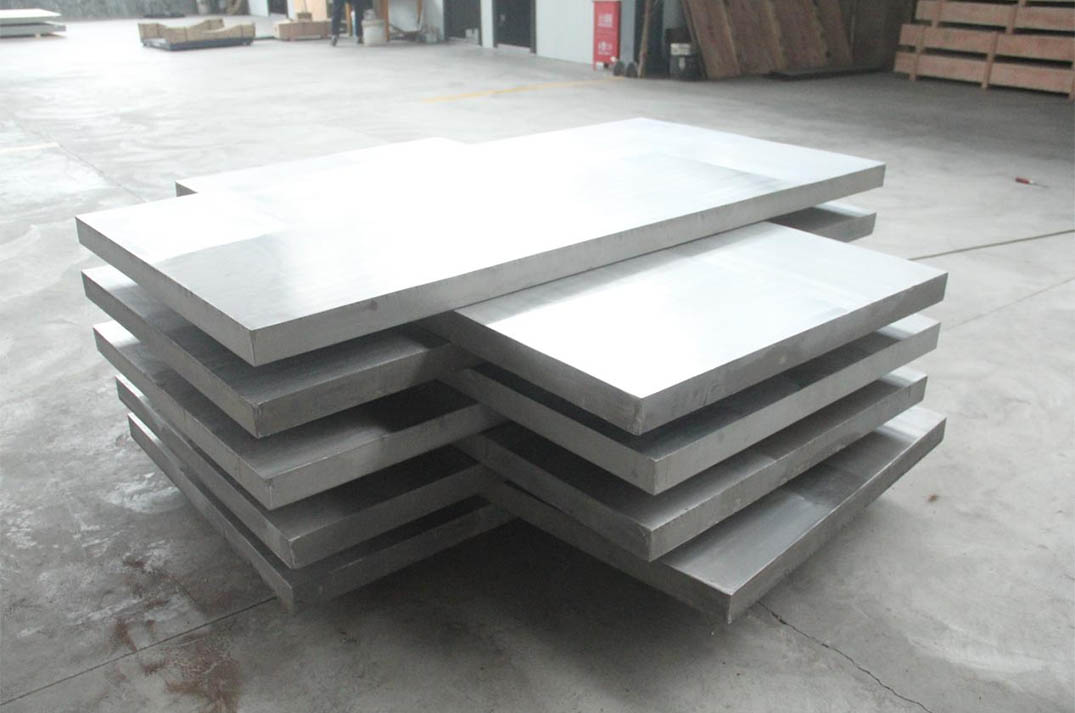

TC4 titanium alloy Manufacturing and Processing Characteristics

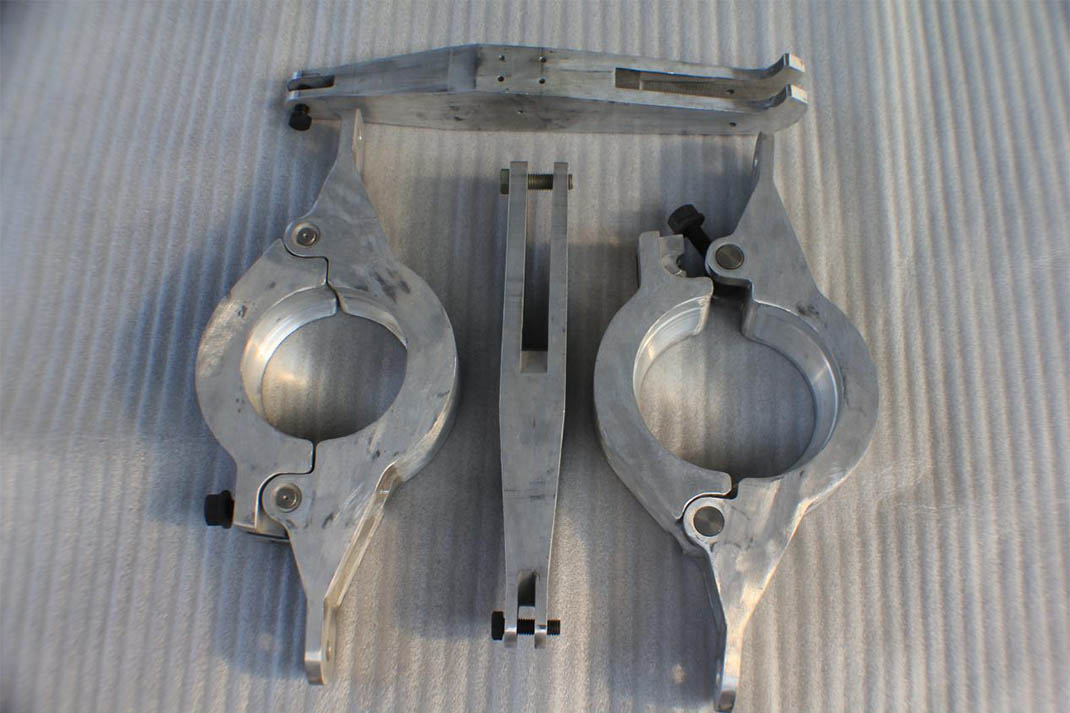

TC4 titanium alloy exhibits good manufacturability and can undergo various processing techniques, including forging, rolling, drawing, and welding. Welding is a crucial process for TC4 titanium alloy manufacturing, requiring precise control of welding parameters to ensure the quality and performance of the weld joints. This manufacturability enables TC4 titanium alloy to meet the demands of complex structural components, providing vital support for modern engineering design and manufacturing.

In conclusion, TC4 titanium alloy is an indispensable material in modern engineering due to its low density, excellent mechanical properties, stable thermal-physical properties, and outstanding chemical stability. With advances in technology and processes, TC4 titanium alloy will continue to play an important role in future engineering design and manufacturing.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский