Thank you for your

attention on Yesheng !

The Titanium Forging Process

The titanium forging process is a critical step in the manufacturing of titanium components that are used in various industries such as aerospace, medical, and automotive. Titanium forgings offer several advantages, including high strength-to-weight ratio, corrosion resistance, and excellent mechanical properties. In this article, we will explore the titanium forging process and highlight some of the leading titanium forging companies, manufacturers, and suppliers in the industry.

The Titanium Forging Process:

Billet Selection: The first step in the titanium forging process is selecting the appropriate titanium billet. Titanium billets are typically produced by melting titanium scrap and converting it into ingots. These ingots are then rolled into sheets or billets.

Forging Preparation: Once the titanium billet is selected, it undergoes heat treatment to increase its plasticity. This heat treatment process, known as solution treatment, involves heating the billet to a high temperature and then quenching it rapidly.

Forging: The heat-treated titanium billet is then placed between two dies and subjected to high pressure to shape it into the desired component. The forging process can be done using open-die forging or closed-die forging, depending on the complexity of the part.

Heat Treatment: After the forging is completed, the titanium component undergoes a series of heat treatments to improve its mechanical properties. These heat treatments include solution treatment, precipitation hardening, and aging.

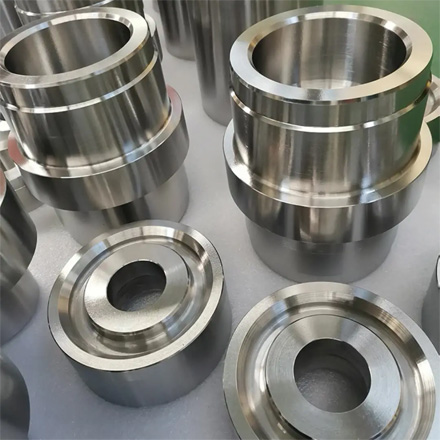

Machining: The forged titanium component is then precision machined to achieve the final dimensions and surface finish. This step ensures that the component meets the required specifications and tolerances.

Leading Titanium Forging Companies:

Yesheng Titanium Industry: Based in China, Yesheng Titanium Industry is a leading manufacturer and supplier of titanium forgings. They offer a wide range of titanium components for various industries, including aerospace, medical, and automotive.

The titanium forging process involves several critical steps, including billet selection, forging preparation, forging, heat treatment, and machining. Titanium forgings offer numerous advantages, making them a preferred choice for applications requiring high strength, corrosion resistance, and excellent mechanical properties. Companies like Yesheng Titanium Industry play a vital role in providing high-quality titanium forgings to meet the demands of various industries.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский