Thank you for your

attention on Yesheng !

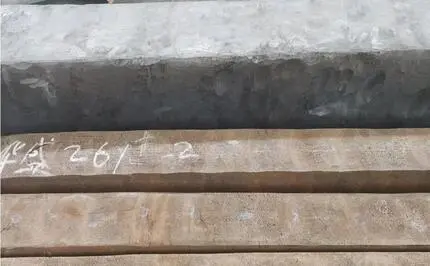

Welding titanium tubing with Yeshengti titanium pipe stock

Welding titanium tubing requires a meticulous procedure and adherence to specific guidelines to ensure a seamless and durable joint. Yeshengti Titanium Pipe Stock stands as a trusted source for premium titanium pipes, and understanding the key steps and considerations in welding titanium tubing is paramount for industries relying on this versatile material. Let's delve into the welding procedure, types of welding suitable for titanium, and the essential considerations for achieving impeccable welds with Yeshengti's titanium pipe stock.

Welding Titanium Tubing Procedure

Type of Welding Used for Titanium

Titanium's unique properties demand a precise welding approach. Gas tungsten arc welding (GTAW), commonly known as TIG welding, is the preferred method for welding titanium tubing. TIG welding allows for controlled heat input, ensuring a high-quality weld without compromising the material's integrity.

Key Steps for Welding Titanium Pipes

Use of Direct Current Negative Polarity

Employ direct current (DC) negative polarity for welding titanium pipes. This ensures a stable arc and proper penetration during the welding process.

Back Purging:

Back purging is a crucial step in welding titanium pipes. It involves eliminating oxygen inside the pipeline to prevent oxidation during the welding process. Various methods, including the use of inert gases, can be employed for effective back purging.

Filler Metal Usage:

When the thickness of the welded titanium pipes exceeds 0.010 inches, it's essential to use filler metal. The filler metal chosen should match the grade of the titanium pipe for optimal compatibility and strength in the weld joint.

Considerations for Welding Titanium Pipes

Low-Temperature Material

Titanium is a low-temperature material, and its welding temperature is lower than that of stainless steel. When working with titanium tubes of 1mm (0.039 inches) thickness, maintaining a lower welding temperature is crucial to prevent any undesirable metallurgical changes in the material.

Avoidance of Incompatible Filler Materials

Titanium welding requires strict adherence to filler material compatibility. It's imperative to avoid using filler materials other than titanium, such as stainless steel or nickel alloy rods. Incompatible filler materials can compromise the integrity of the weld and the overall performance of the titanium tubing for sale and more custom titanium products.

Advantages of Welding Titanium Tubing with Yeshengti Titanium Pipe Stock

Premium Quality Titanium Pipes

Yeshengti Titanium Pipe Stock provides premium quality titanium pipes that serve as a solid foundation for welding applications. The pipes are crafted with precision, ensuring consistency and reliability in the welding process.

Versatility in Applications

The versatility of Yeshengti's titanium pipes extends to various industries, including aerospace, medical, chemical processing, and more. The suitability of these pipes for diverse applications makes them a preferred choice for welding projects in different sectors.

Customization Options

Yeshengti offers customization options in terms of lengths, diameters, and specifications. This ensures that industries can acquire titanium pipes tailored to their specific welding requirements, promoting efficiency and accuracy in the welding process.

Corrosion Resistance

Titanium's inherent corrosion resistance, coupled with the premium quality of Yeshengti's pipes, ensures that the welded joints maintain their integrity even in corrosive environments. This is particularly advantageous in industries such as chemical processing where resistance to corrosion is crucial.

Welding titanium tubing with Yeshengti Titanium Pipe Stock involves a meticulous procedure that aligns with the unique characteristics of this exceptional material. By following the recommended steps and considerations, industries can achieve high-quality welds that meet stringent standards. Yeshengti's titanium factory commitment to providing premium titanium pipes adds a layer of reliability to welding projects across diverse industries, contributing to the advancement of technology and infrastructure through the seamless integration of titanium tubing.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский