Thank you for your

attention on Yesheng !

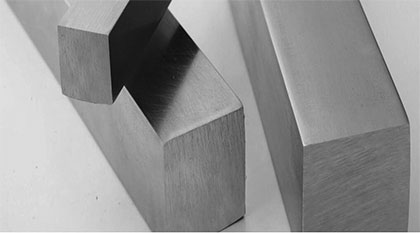

What is Titanium Square Stock?

Titanium square stock represents one of the most versatile materials extensively used in a myriad of industries. Produced from a metal well-regarded for its incredible strength-to-weight ratio, excellent corrosion resistance, and biocompatibility, titanium square stock is a favored choice for applications that demand high performance and durability. Available in various sizes and lengths, this material has become indispensable in fields ranging from aerospace to medical technology. But what makes titanium square stock so special? Let's explore its properties, applications, manufacturing processes, and how it compares to other materials.

Properties of Titanium Square Stock

When discussing the properties of titanium square stock, it's essential to recognize its two defining characteristics: light weight and high strength. Titanium is approximately 45% lighter than steel yet has comparable strength, making it ideal for applications where weight savings are crucial.

1. Corrosion Resistance: One of the standout properties of titanium square stock is its resistance to corrosion. Titanium naturally forms a thin oxide layer that protects it from rust and other forms of corrosion, even in harsh environments such as seawater or acidic exposure.

2. High Strength and Low Density: Titanium square stock boasts an impressive strength-to-weight ratio. Its high tensile strength can endure substantial stress, while its low density ensures that the material remains lightweight.

3. Biocompatibility: Titanium is uniquely compatible with human tissue, which is why it is extensively used in medical devices, implants, and surgical instruments.

4. Thermal Stability: The material can withstand extreme temperatures without losing its mechanical properties, making it suitable for high-temperature applications.

5. Electrical Conductivity: Although not as conductive as metals like copper, titanium square stock offers useful electrical conductivity properties, which can be advantageous in certain applications.

Applications of Titanium Square Stock

Owing to its exceptional properties, titanium square stock finds utility in various high-stakes industries:

1. Aerospace and Defense: The aerospace sector benefits significantly from the high strength and low weight of titanium square stock. It is used in aircraft structures, fasteners, and spacecraft components, allowing for better fuel efficiency and enhanced performance.

2. Medical Technology: Because of its biocompatibility, titanium square stock is a primary material in medical implants, dental devices, and surgical instruments. It interacts well with the human body's tissues and can last for years without degrading.

3. Marine Engineering: The corrosion resistance of titanium square stock makes it ideal for underwater applications, including shipbuilding, offshore drilling rigs, and underwater pipelines.

4. Automotive Industry: High-performance and luxury vehicles often incorporate titanium parts made from square stock to reduce weight and improve fuel efficiency without compromising strength.

5. Chemical Processing: In environments where materials are exposed to corrosive substances, titanium square stock proves invaluable. It is often used in heat exchangers, reaction vessels, and piping.

Manufacturing Processes for Titanium Square Stock

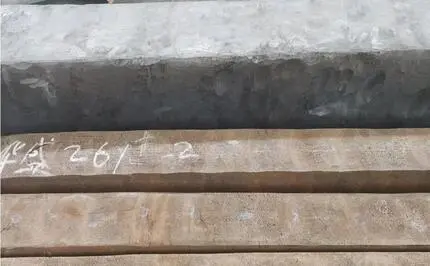

The production of titanium square stock involves several meticulous steps to ensure the material meets industry standards:

1. Extraction: The primary raw material for producing titanium is the mineral ilmenite or rutile, which is processed to produce titanium dioxide. The Kroll process is then used to convert titanium dioxide into titanium sponge.

2. Melting and Casting: The titanium sponge is melted, often in a vacuum arc furnace, to produce a high-purity titanium ingot. This ingot is then cast into a more workable form.

3. Forming: The ingot undergoes multiple mechanical processes such as forging, rolling, or extrusion to form square bars of desired dimensions.

4. Heat Treatment: To enhance mechanical properties like strength and ductility, the titanium square stock is subjected to various heat treatments.

5. Finishing: The final steps include surface treatments, machining, and quality checks to ensure the titanium square stock meets stringent industry specifications.

Comparing Titanium Square Stock to Other Materials

Understanding how titanium square stock stacks up against other materials helps in selecting the best option for specific applications:

1. Steel: While steel is stronger, titanium offers a much better strength-to-weight ratio. Additionally, titanium is far more resistant to corrosion, making it preferable in corrosive environments.

2. Aluminum: Aluminum is lightweight like titanium but lacks in strength and corrosion resistance. For applications where these factors are critical, titanium is the superior choice.

3. Carbon Fiber: Carbon fiber offers excellent strength-to-weight ratios but can be brittle and less impact-resistant. Titanium square stock provides a balance of strength, ductility, and durability.

4. Plastics: High-performance plastics are lighter and corrosion-resistant but generally can't match the strength and thermal stability of titanium square stock.

Titanium square stock exemplifies a material that stands out due to its exceptional properties and broad range of applications. From aerospace to medical technology, its unique characteristics provide unparalleled benefits, ensuring it remains a material of choice for high-performance needs.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский