Thank you for your

attention on Yesheng !

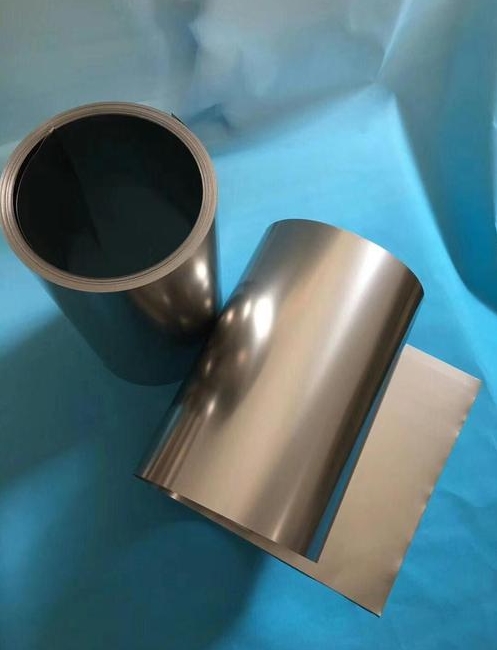

“Approaching Titanium Alloys”: Surface Treatment

Titanium is generally considered a difficult material to process due to its high resistance to deformation and low plasticity, particularly when alloyed, which presents additional challenges. Moreover, adhesion during processing adversely affects surface quality. The former is an inherent property of the material, while the latter is approached from the perspective of lubrication to prevent adhesion.

Typically, all metals experience some degree of wear or adhesion under friction. This can usually be minimized by appropriately selecting lubricants and types of metals in contact. However, for titanium and titanium alloys, which are prone to adhesion, such choices are rather limited. Therefore, preventing adhesion is a critical issue in titanium processing. In the drawing process of pipes, rods, and wires, almost all lubricants struggle to completely prevent adhesion.

Before drawing titanium and titanium alloy pipes, rods, and wires, surface treatments are generally carried out, including surface oxidation, coating, and metal film plating. These are then supplemented with lubricants made of molybdenum disulfide and soap powder. When drawing fine wires, soap water is typically used as an auxiliary lubricant.

Surface treatments to prevent adhesion in titanium and titanium alloys include surface oxidation, fluorophosphate treatment, and metal film plating with copper, chromium, nickel, and tin. Among these, oxidation and coating treatments are more commonly used.

Due to the tendency of titanium alloys to adhere to molds during drawing, which makes wire drawing difficult, in addition to using good lubricants, other measures such as coating and oxidation should also be employed to enhance lubrication. Before drawing, titanium alloys are mostly subjected to oxidation and coating treatments. Common coatings include graphite emulsion, salt-lime, and calcium-based coatings. The choice of coating depends not only on its ability to bond tightly with the wire material but also on its good wettability with the lubricant and ease of removal. Different drawing process conditions require different lubricants. Commonly used lubricants include industrial soap powder, graphite emulsion, and mixtures of soap powder with other materials. Lubricants should be selected for good wettability with the coating and high thermal stability.

Before hot drawing titanium alloy products, a graphite emulsion is often applied for process lubrication. This is because a graphite coating not only serves a lubricating function but also protects the surface of the billet from oxidation during heating or hot drawing. The specific requirements for the graphite emulsion are: a graphite content of about 20%-25%, minimal content of other impurities, a graphite particle size between 1-3 microns, and the ability to adhere firmly and evenly to the surface of the billet being drawn.

1、Salt-Lime Coating

The formula for the salt-lime lubricant layer is: 12% Na₂SO₄ + 12% CaO + 0.3% Na₃PO₄ + 0.2% NaCl + the remaining amount of water. Additionally, a mixture of 75% soap powder and 25% sulfur powder is used as a solid powder lubricant.

2、Fluorophosphate Treatment

After cleaning the metal billet surface using physical methods, a modified coating film is formed on the surface by immersing it in a solution. Then, a solid lubricant is applied over the modified coating film. The resulting lubricant has strong adhesion to the substrate, a low friction coefficient during drawing, and wear resistance. This method is suitable for continuous, multi-pass, large-deformation cold processing of high-strength, low-plasticity titanium alloys, where no adhesion or demolding occurs during cold processing, and the lubricant is easily removed afterward.

3、Boronizing Treatment

Titanium alloy wires are immersed in a boiling mixed solution of KBF₄, BaCl₂, and NH₄NO₃, then taken out, washed with water, and dried. After this treatment, the wire surface appears gray-black. A coating is then applied, forming a layer of fluoroborate on the surface of the titanium alloy wire. During cold heading, a layer of molybdenum disulfide must be applied as a lubricant on the wire surface; otherwise, the coating will be scraped off by the reduction area of the die, not only failing to provide lubrication but also acting as an obstacle.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский