Thank you for your

attention on Yesheng !

“Approaching Titanium Alloys”: TC4 Titanium Alloy

TC4 (Ti-6Al-4V) titanium alloy is a typical alpha+beta dual-phase titanium alloy and is currently the most widely used and well-developed titanium alloy. This alloy is characterized by its low density, high specific strength, good thermal stability, and excellent weldability, making it highly effective for various applications. It is widely used as a load-bearing structural material in aerospace, marine, automotive, and electrical industries. For example, in the aerospace industry, TC4 titanium alloy by titanium manufacturing companies can be used to manufacture the shells of space rockets, fan blades of aircraft engines, various beams, frames, slides, landing gear beams, and other main load-bearing structural components, as well as various types of fasteners.

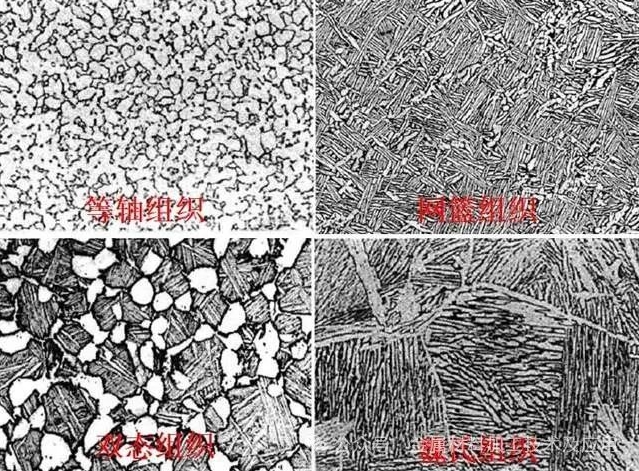

The performance of a material is determined by its microstructure, and different types of microstructures determine different mechanical properties, allowing for application in various working environments. As one of custom titanium products, TC4 titanium alloy is highly sensitive to changes in microstructure resulting from heat treatment processes. Different characteristics of microstructures, such as the ratio, morphology, and distribution of the two phases, can be achieved through heat treatment and deformation processing. The common microstructures of TC4 titanium alloy include the following four types: equiaxed, basketweave, bimodal, and Widmanstätten structures, as shown in the figure below.

1) Equiaxed Structure:

The equiaxed structure is characterized by the presence of more than 30% equiaxed alpha phase distributed on the beta-transformed matrix. This structure is generally formed at temperatures 30-100°C below the beta transition temperature point, following sufficient recrystallization annealing and substantial plastic deformation. The lower the annealing temperature and the more extensive the plastic deformation, the finer and higher the proportion of equiaxed alpha phase grains. The equiaxed structure has excellent overall performance and is widely used today, offering high elongation, cross-sectional reduction rates, and excellent plasticity. However, it has poor impact resistance, high-temperature performance, fracture toughness, and creep strength.

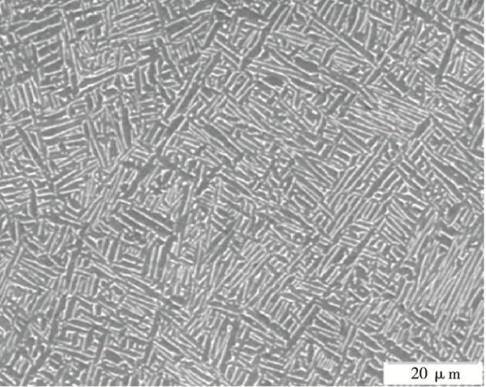

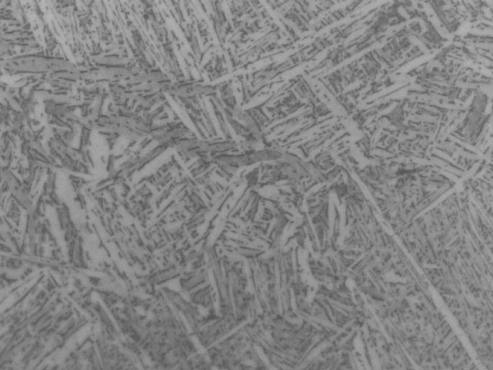

2) Basketweave Structure:

The basketweave structure features interwoven plate-like alpha phases distributed on the beta-transformed matrix, forming an overall basket-like pattern. This structure is generally formed when heated or deformed in the beta phase region and deformation is terminated in the alpha+beta two-phase region. If there is significant deformation in the two-phase region, the short plate-like alpha phase will spheroidize to form an equiaxed structure. The basketweave structure has high creep strength and good creep resistance, with excellent thermal strength, making it suitable for producing components used at high temperatures for extended periods. Moreover, this type of structure has a low fatigue crack growth rate, making it suitable for structural components with high damage tolerance requirements. However, the basketweave structure has poor plasticity and low thermal stability and may exhibit "beta brittleness." The way to avoid this is to shorten the heating time and temperature in the beta phase region and reduce the size of the original beta grains.

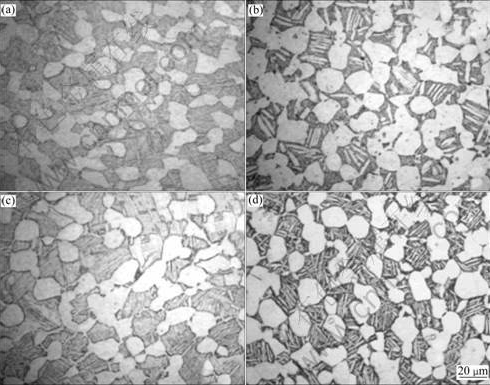

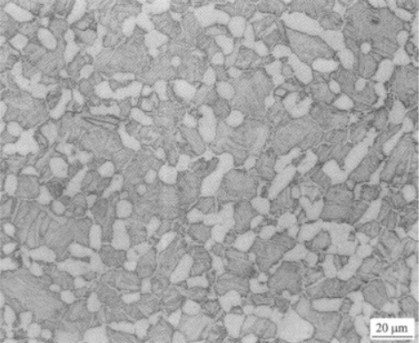

3) Bimodal Structure:

The bimodal structure consists of two types of microstructures: one is the equiaxed alpha phase, with a content of no more than 30%; the other is the beta-transformed structure, with lamellar alpha and beta phases arranged alternately. This structure is generally obtained through annealing or deformation at high temperatures in the alpha+beta two-phase region. Because the bimodal structure exhibits the morphological characteristics of both equiaxed and basketweave structures, it also combines the performance advantages of both. Compared to the equiaxed structure, the bimodal structure has higher fracture toughness, fatigue resistance, creep strength, and long-term strength. Compared to the basketweave structure, the bimodal structure offers better plasticity, heat resistance, room temperature strength, and fatigue resistance.

4) Widmanstätten Structure:

In the Widmanstätten structure, the original coarse beta grain boundaries are clearly visible. The beta grains consist of alternating lamellar alpha and beta phases arranged in a beta-transformed structure, with the lamellar alpha phase being slender, straight, and having a high aspect ratio with parallel arrangement. This type of structure is formed when the heating temperature in the beta single-phase region is too high and the degree of deformation is low, followed by slow cooling. The Widmanstätten structure has excellent creep resistance, long-term strength, and fracture toughness. However, due to the presence of coarse original beta grains and continuous alpha grain boundaries, its plasticity is very poor, similar to overheated structures in steel. This should be avoided as much as possible in actual production processes.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский