Thank you for your

attention on Yesheng !

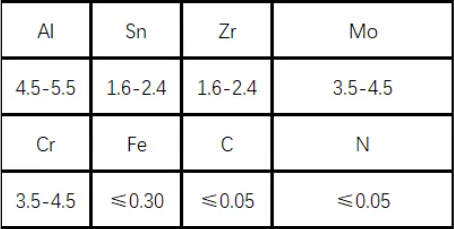

Detailed Discussion on Ti5Al2Sn2Zr4Mo4Cr Titanium Alloy Processing Technology

I. Characteristics of Ti5Al2Sn2Zr4Mo4Cr Titanium Alloy

High Strength and Toughness: Ti5Al2Sn2Zr4Mo4Cr titanium alloy has excellent strength and toughness, meeting the requirements for high structural efficiency and reliability.

High Hardenability: Its high hardenability allows for a uniform microstructure during heat treatment.

Wide Forging Temperature Range: The wide forging temperature range provides greater flexibility in processing.

Corrosion Resistance: It has good general corrosion resistance, but its sensitivity to hot salt stress corrosion must be considered.

II. Ti5Al2Sn2Zr4Mo4Cr Titanium Alloy Processing Technology

1. Forging Technology

Traditional Die Forging: Ti5Al2Sn2Zr4Mo4Cr titanium alloy billets are typically produced using traditional die forging processes, which ensure precise shape and size of the forgings.

Open Die Forging: Although less commonly used for Ti5Al2Sn2Zr4Mo4Cr titanium alloy production, open die forging has lower production costs and greater operability. By controlling the forging process, different microstructures such as equiaxed and basketweave structures can be obtained. Different forging processes affect the microstructure and mechanical properties of the forgings. For example, specific heating and deformation control can result in a uniform, fine basketweave structure, improving the tensile strength, yield strength, and impact properties at room temperature.

2. Heat Treatment Technology

Solution Treatment: Solution treatment is a crucial step for adjusting the microstructure and properties of Ti5Al2Sn2Zr4Mo4Cr titanium alloy. Depending on the forging process, the temperature and duration of the solution treatment vary. For β-forged materials, the solution treatment temperature is 800℃±10℃, with a 4-hour hold followed by water quenching. For α+β forged materials, a combination treatment of 840℃±10℃ air cooling followed by 800℃±10℃ water quenching is used.

Aging Treatment: Aging treatment involves holding the alloy at a specific temperature range for an extended period to further adjust its properties. The typical aging temperature for Ti5Al2Sn2Zr4Mo4Cr titanium alloy ranges from 585℃ to 685℃, with a standard aging process being 630℃ for 8 hours followed by air cooling.

Stress Relief Annealing: Stress relief annealing is mainly used to eliminate internal stresses generated during processing, enhancing the alloy's stability and service life. The stress relief annealing temperature generally does not exceed the aging temperature, with a hold time typically ranging from 1 to 4 hours.

3. Surface Treatment Technology

Pickling: Pickling is a critical step for removing surface oxides and impurities from Ti5Al2Sn2Zr4Mo4Cr titanium alloy. Commonly used pickling solutions consist of hydrofluoric acid and nitric acid. By controlling the pickling process parameters, surface cleanliness can be ensured.

Anodizing: Anodizing can form a dense oxide film on the surface of Ti5Al2Sn2Zr4Mo4Cr titanium alloy, improving its corrosion resistance and aesthetics. By controlling the electrolyte, voltage, temperature, and time parameters, an ideal oxide film can be obtained.

III. Ti5Al2Sn2Zr4Mo4Cr Titanium Alloy Application Fields

Thanks to its excellent properties, Ti5Al2Sn2Zr4Mo4Cr titanium alloy is widely used in aerospace, marine engineering, and biomedical fields. For instance, in the aerospace sector, Ti5Al2Sn2Zr4Mo4Cr titanium alloy is used to manufacture critical components such as aircraft wing skins, engine blades, and structural parts. In marine engineering, it is used for submarine hulls and offshore platform components.

The processing technology of Ti5Al2Sn2Zr4Mo4Cr titanium alloy involves various aspects such as forging, heat treatment, and surface treatment. By optimizing these process parameters, the performance and application scope of Ti5Al2Sn2Zr4Mo4Cr titanium alloy can be further enhanced.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский