Thank you for your

attention on Yesheng !

Overview of Eight Metal Forming Processes:Processes, Advantages, Disadvantages, and Applications

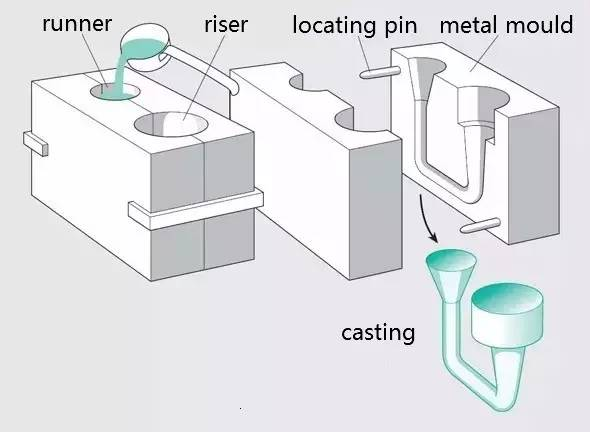

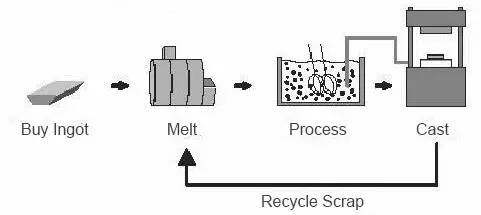

1. Casting

Casting is the process where liquid metal is poured into a mold that matches the shape and size of the desired part, then allowed to cool and solidify, resulting in a rough or finished part. This is typically referred to as liquid metal forming or casting.

Process Flow:

Liquid Metal → Mold Filling → Solidification Shrinkage → Casting

Characteristics:

Can produce parts with complex shapes, especially those with complex internal cavities.

Highly adaptable, with no restrictions on alloy types or casting sizes.

Widely available material sources; scrap can be remelted; low equipment investment.

High defect rate, lower surface quality, and poor working conditions.

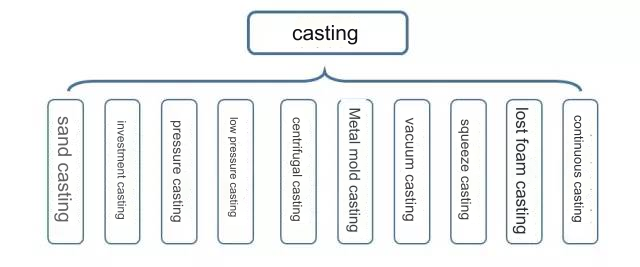

Types of Casting:

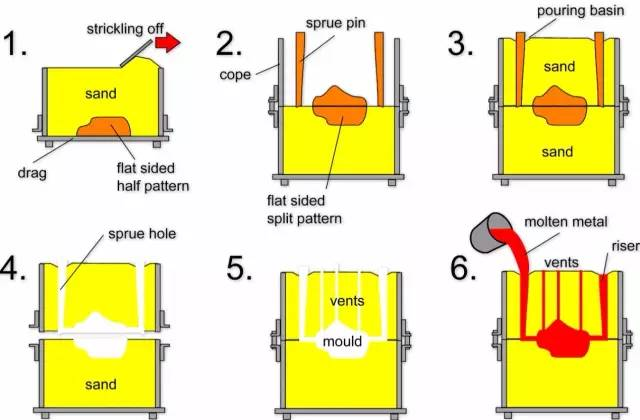

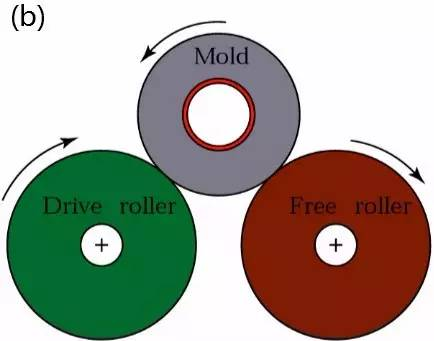

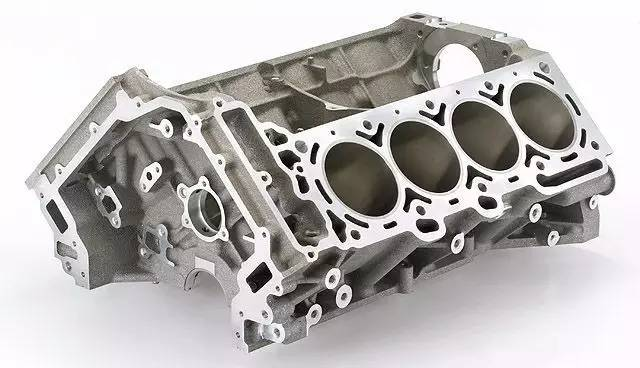

(1)Sand Casting

Sand casting involves producing castings in sand molds. Steel, iron, and most non-ferrous alloy castings can be produced using sand casting.

Process Flow:

Technical Characteristics:

Suitable for making complex shapes, especially those with complex internal cavities.

Wide adaptability and low cost.

For materials with poor plasticity, like cast iron, sand casting is the only forming process available.

Applications: Engine blocks, cylinder heads, crankshafts, etc.

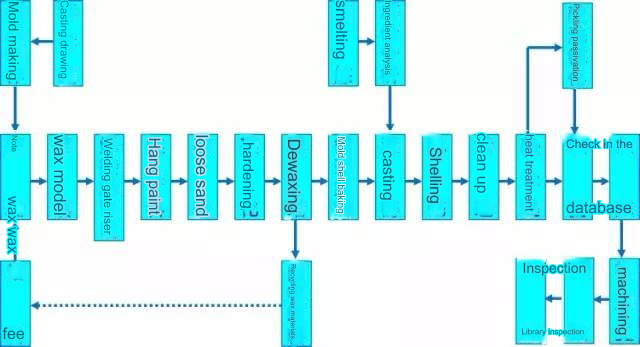

(2)Investment Casting

Investment casting, also known as lost-wax casting, involves creating a wax pattern, covering it with refractory material to form a shell, melting the wax out to leave a cavity, and then pouring metal into the cavity to form the casting.

Process Flow:

Advantages:

High dimensional and geometric accuracy.

High surface roughness.

Ability to cast complex shapes and unlimited alloys.

Disadvantages: Complex process and higher cost.

Applications: Small parts with complex shapes and high precision, such as turbine blades.

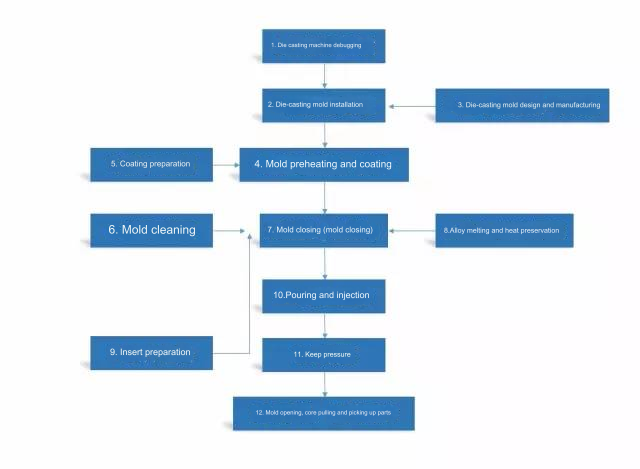

(3)Die Casting

Die casting uses high pressure to force liquid metal into a precision metal mold cavity. The metal solidifies under pressure to form a casting.

Process Flow:

Advantages:

High-pressure and fast metal flow during casting.

High-quality products with stable dimensions and good interchangeability.

High production efficiency with long-lasting molds.

Suitable for mass production, offering good economic benefits.

Disadvantages:

Castings are prone to small pores and shrinkage cavities.

Die castings have low plasticity and are unsuitable for impact loads and vibrations.

Low mold life for high melting point alloys, affecting production expansion.

Applications: Initially used in the automotive and instrumentation industries, now extended to agriculture, machinery, electronics, defense, computing, medical equipment, clocks, cameras, and daily hardware.

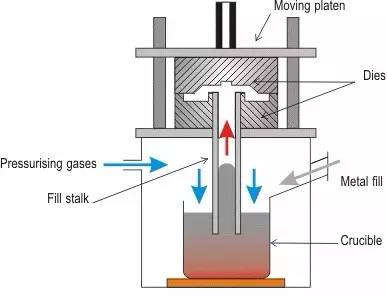

(4)Low-Pressure Casting

Low-pressure casting involves filling the mold with liquid metal under low pressure (0.02-0.06 MPa) and solidifying it under pressure to form the casting.

Process Flow:

Technical Characteristics:

Adjustable pouring pressure and speed, suitable for various molds and alloys.

Smooth mold filling, reducing gas entrapment and improving casting quality.

Dense castings with clear contours and high mechanical properties.

Higher metal utilization (90-98%) with reduced labor intensity and good automation potential.

Applications: Traditional products like cylinder heads, wheels, and cylinder frames.

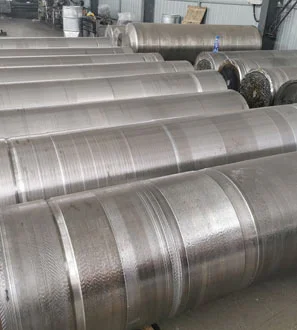

(5)Centrifugal Casting

Centrifugal casting involves pouring liquid metal into a rotating mold, where centrifugal force fills the mold and solidifies the casting.

Process Flow:

Advantages:

Minimal metal waste in the gating system, increasing yield.

No cores needed for hollow castings, improving metal filling ability.

High density and mechanical properties with fewer defects.

Suitable for producing composite metal castings.

Disadvantages:

Limited to certain shapes.

Rough internal surfaces and inaccurate inner diameters.

Prone to segregation.

Applications: Common in metallurgical, mining, transportation, irrigation, aviation, defense, and automotive industries, especially for cast iron pipes, engine liners, and bushings.

(6)Gravity Die Casting

Gravity die casting involves filling a metal mold with liquid metal under gravity and solidifying it to form the casting.

Process Flow:

Advantages:

High cooling rates result in dense castings with superior mechanical properties.

High dimensional accuracy and low surface roughness.

Improved working conditions with minimal or no core use.

Disadvantages:

No permeability in the metal mold, requiring measures to vent gases.

Prone to cracks due to lack of mold compliance.

Long mold manufacturing time and high cost, making it economical only for mass production.

Applications: Suitable for mass-producing complex aluminum, magnesium, and other non-ferrous alloy castings, as well as steel and iron castings.

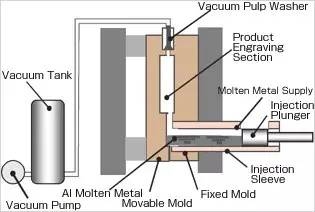

(7)Vacuum Die Casting

Vacuum die casting involves removing gases from the mold cavity during the casting process to reduce porosity and improve casting quality.

Process Flow:

Advantages:

Reduces or eliminates internal porosity, enhancing mechanical properties and surface quality.

Allows lower pressures and poorer casting alloys, potentially using smaller machines for larger castings.

Improves filling conditions, enabling thinner castings.

Disadvantages:

Complex mold sealing structures, increasing manufacturing and installation difficulty and cost.

Effectiveness varies with control precision.

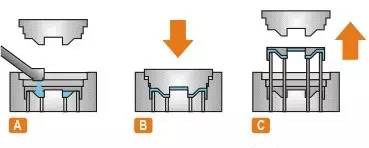

(8)Squeeze Casting

Squeeze casting involves solidifying and shaping liquid or semi-solid metal under high pressure to directly obtain parts or blanks.

Process Flow:

Direct squeeze casting: Coating → Pouring alloy → Mold closing → Pressurizing → Holding pressure → Releasing pressure → Mold opening → Blank removal → Reset. Indirect squeeze casting: Coating → Mold closing → Feeding → Mold filling → Pressurizing → Holding pressure → Releasing pressure → Mold opening → Blank removal → Reset.

Technical Characteristics:

Eliminates defects like porosity and shrinkage.

Low surface roughness and high dimensional accuracy.

Prevents casting cracks.

Facilitates automation.

Applications: Suitable for producing various alloy types like aluminum, zinc, copper, and ductile iron.

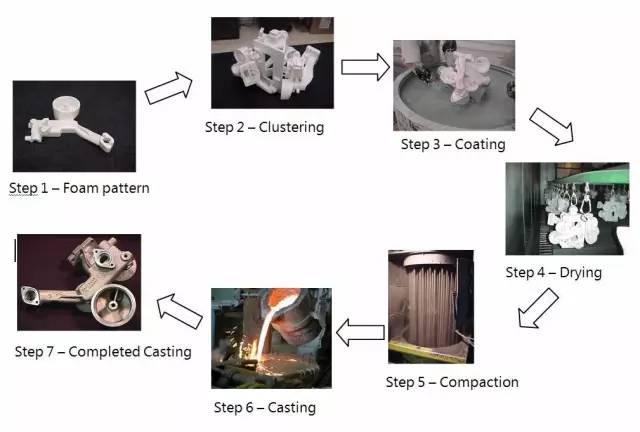

(9)Lost Foam Casting

Lost foam casting, also known as full mold casting, uses foam patterns that match the casting's shape and size. These patterns are coated with refractory material, dried, and buried in sand. When poured with liquid metal, the foam evaporates, and the metal takes its place.

Process Flow: Pre-foaming → Pattern forming → Coating → Drying → Molding → Pouring → Sand removal → Cleaning

Technical Characteristics:

High casting precision with no cores, reducing machining time.

No parting lines, offering high design flexibility.

Clean production with no pollution.

Reduced investment and production costs.

Applications: Suitable for producing complex and precise castings of various sizes and alloys, such as gray iron engine blocks and high manganese steel elbows.

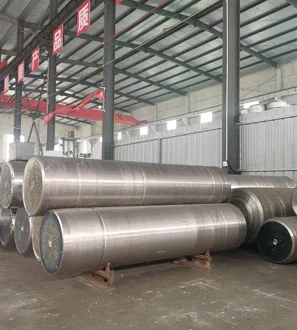

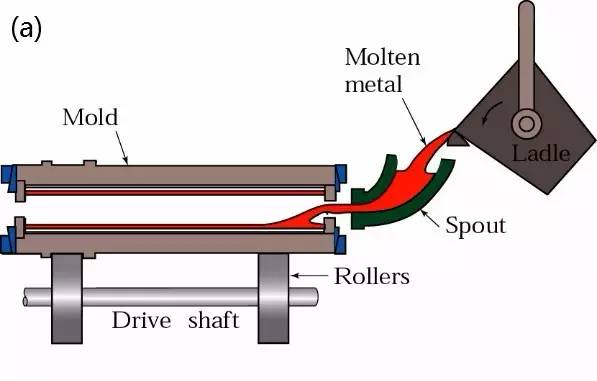

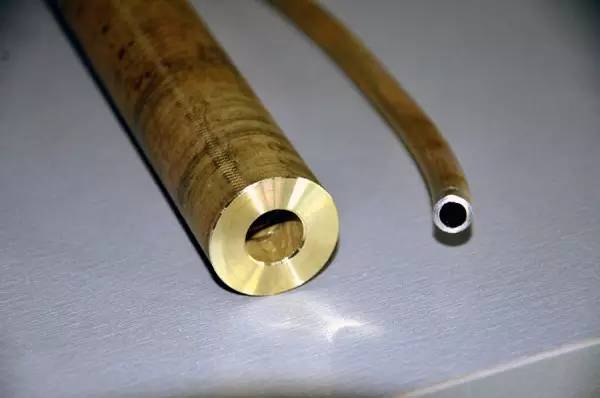

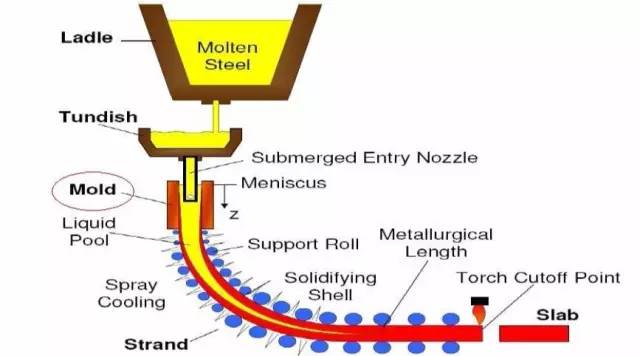

(10)Continuous Casting

Continuous casting is an advanced method where molten metal is continuously poured into a special mold called a crystallizer, and solidified castings are continuously pulled out from the other end, producing castings of any length or specific lengths.

Process Flow:

Technical Characteristics:

Rapid cooling leads to dense and uniform crystals, enhancing mechanical properties.

Saves metal and increases yield.

Simplifies processes, eliminating molding steps and reducing labor intensity.

Facilitates automation, increasing production efficiency.

Applications: Suitable for casting steel, iron, copper, aluminum, magnesium alloys, and other long products like billets, slabs, bars, and tubes.

2.Plastic Forming

Plastic forming utilizes the plasticity of materials to process parts with minimal or no cutting by applying external forces using tools and molds. It includes various methods such as forging, rolling, extrusion, drawing, and stamping.

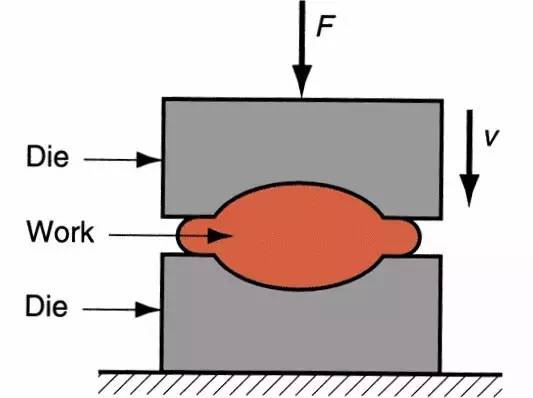

(1)Forging

Forging is a method where pressure is applied to metal billets using forging machinery to induce plastic deformation and obtain forged parts with specific mechanical properties, shapes, and sizes.

Types of Forging:

Free Forging: Uses simple tools to hammer metal ingots or blocks into the desired shape and size, typically done on hammers or hydraulic presses.

Die Forging: Uses molds to shape the metal on forging hammers or hot forging presses.

Ring Rolling: Produces ring-shaped parts of different diameters using specialized equipment, also used for automotive wheel hubs, train wheels, etc.

Special Forging: Includes methods like roll forging, wedge rolling, radial forging, and liquid die forging, suitable for producing special-shaped parts.

Process Flow: Billet heating → Roll forging preform → Die forging → Trimming → Punching → Straightening → Intermediate inspection → Forging heat treatment → Cleaning → Straightening → Inspection

Technical Characteristics:

Forged parts are of higher quality than castings, able to withstand greater impact forces, with superior plasticity, toughness, and mechanical properties, even better than rolled parts.

Saves raw materials and reduces processing time.

High production efficiency.

Free forging is suitable for single-piece or small-batch production, offering high flexibility.

Applications: Large rolling mill rolls, helical gears, turbine generator rotors, impellers, retaining rings, massive hydraulic press cylinders and columns, locomotive axles, automotive and tractor crankshafts, connecting rods, etc.

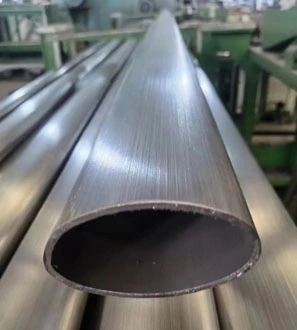

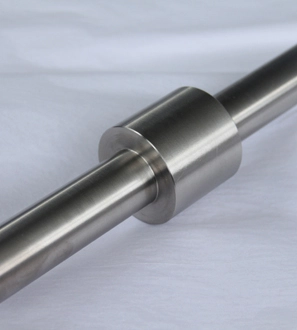

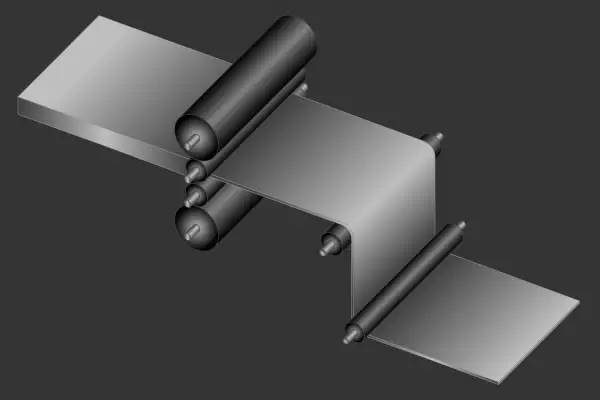

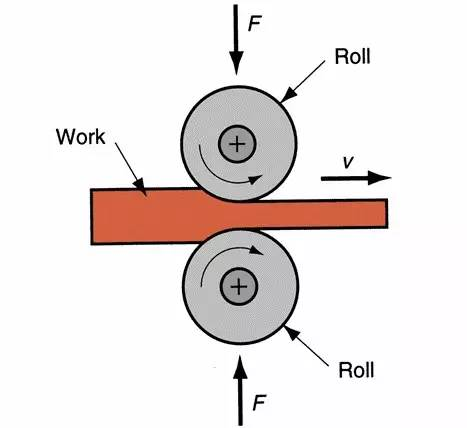

(2)Rolling

Rolling involves passing metal billets through a pair of rotating rolls (various shapes), compressing them to reduce their cross-section and increase their length.

Rolling Classification:

Longitudinal Rolling: The metal passes between two rolls rotating in opposite directions, undergoing plastic deformation.

Transverse Rolling: The deformed material moves in the same direction as the roll axis.

Cross Rolling: The billet moves in a helical pattern, with the billet and roll axis at a specific angle.

Applications: Mainly used for metal materials like profiles, plates, and tubes, as well as some non-metal materials like plastic and glass products.

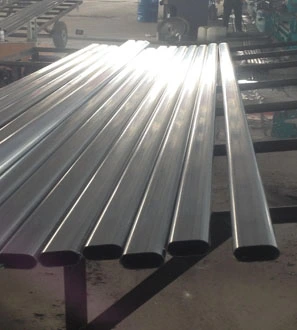

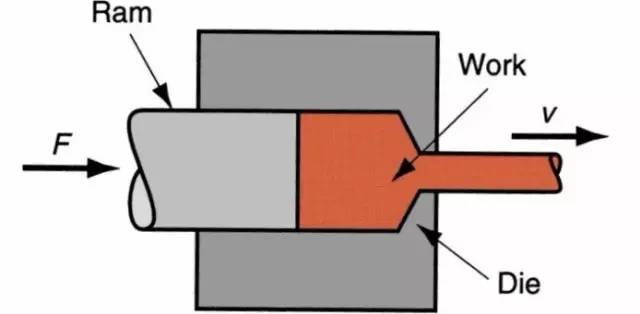

(3)Extrusion

Extrusion is a process where metal billets are pushed through a die or opening under three-way uneven compressive stress, reducing their cross-section and increasing their length to produce the desired products.

Process Flow: Pre-extrusion preparation → Billet heating → Extrusion → Stretching and straightening → Sawing (cutting to length) → Sampling and inspection → Artificial aging → Packaging and storage

Advantages:

Wide production range, diverse specifications, and product variety.

High production flexibility, suitable for small-batch production.

High dimensional accuracy and good surface quality of products.

Low equipment investment, small plant area, and easy to automate.

Disadvantages:

Significant geometric scrap loss.

Uneven metal flow.

Low extrusion speed, long auxiliary time.

High tool wear and cost.

Production Range: Mainly used for manufacturing long rods, deep holes, thin walls, and special cross-section parts.

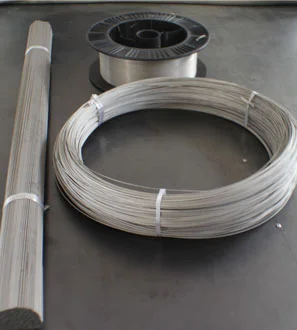

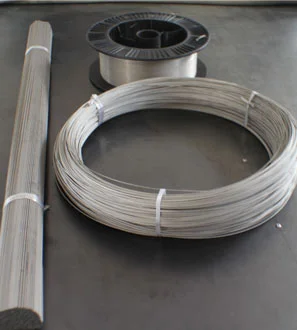

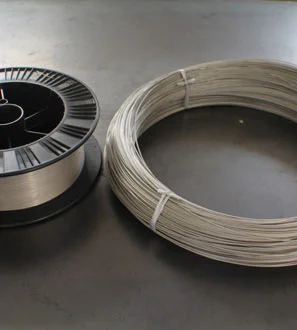

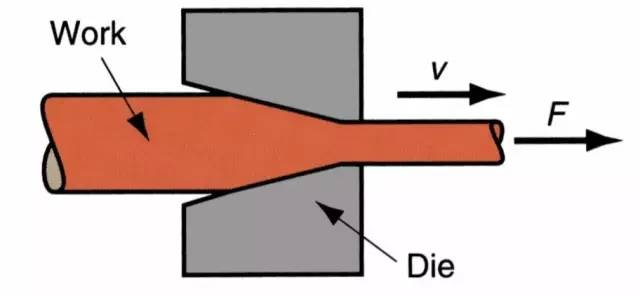

(4)Drawing

Drawing involves applying external force to the front end of the metal billet, pulling it through a die or opening smaller than the billet's cross-section to obtain products with the desired shape and size.

Advantages:

Precise dimensions and smooth surface.

Simple tools and equipment.

Continuous, high-speed production of small cross-section long products.

Disadvantages:

Limited deformation per pass and total deformation between anneals.

Length limitations.

Production Range: Drawing is the main processing method for metal tubes, bars, profiles, and wires.

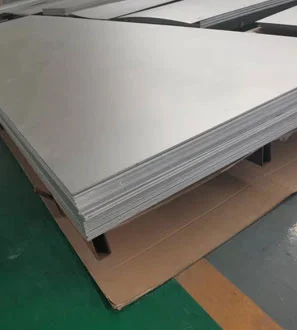

(5)Stamping

Stamping involves applying external force to sheet metal, strip, tube, and profile materials using a press and mold, causing plastic deformation or separation to obtain parts (stamping parts) of the desired shape and size.

Technical Characteristics:

1.Produces lightweight, high-rigidity products.

2.Good productivity, suitable for mass production with low cost.

3.Produces uniformly high-quality products.

4.High material utilization, good shearing and recyclability.

Applications: Around 60-70% of the world's steel is sheet metal, with most finished through stamping. Automotive bodies, chassis, fuel tanks, radiator fins, boiler shells, container shells, motor and electrical silicon steel sheets, as well as numerous products in instruments, household appliances, bicycles, office machinery, and daily utensils contain stamped parts.

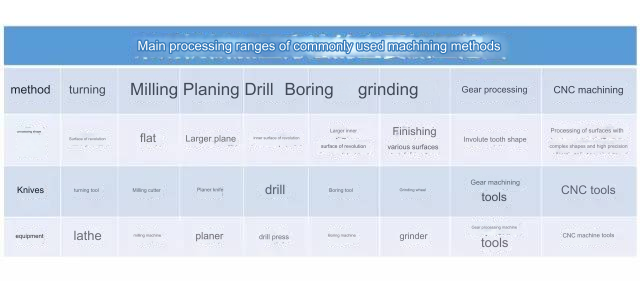

3.Machining

Machining involves removing excess metal layers from a raw part using cutting tools to achieve the technical requirements of dimensional accuracy, shape, positional accuracy, and surface quality as specified in the drawings.

Common Machining Methods:

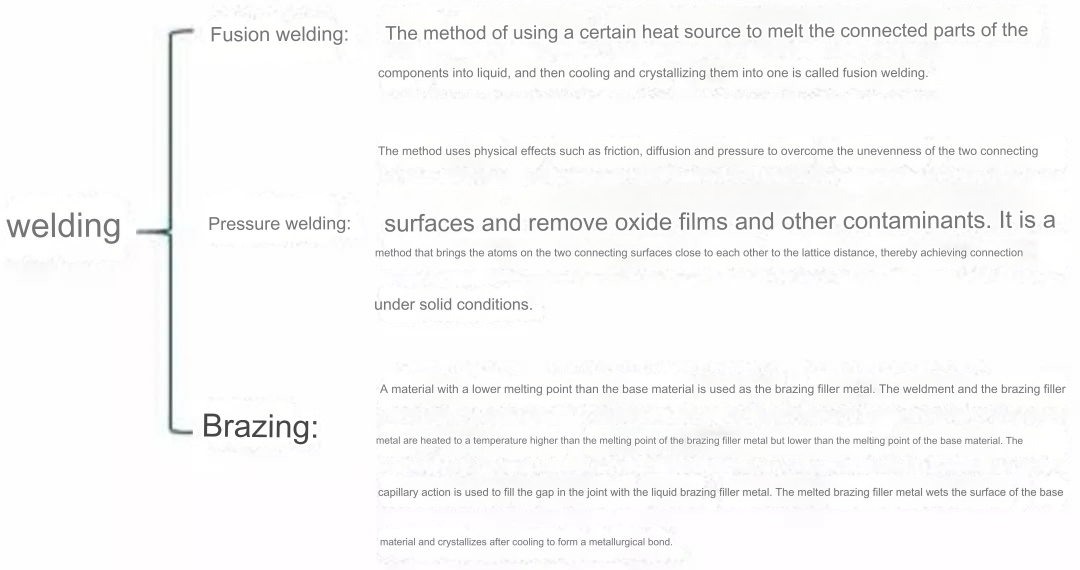

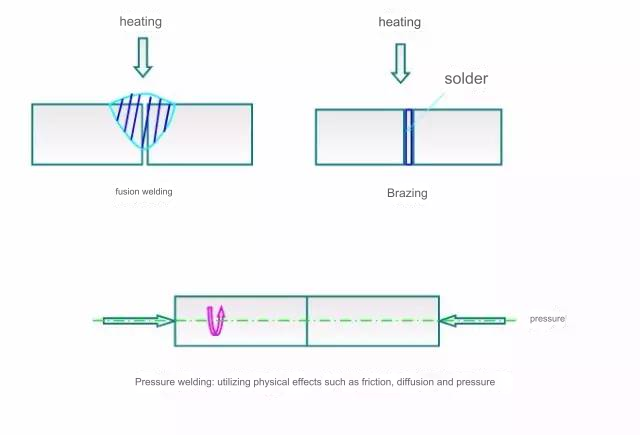

4.Welding

Welding, also known as fusion welding, is a process that joins metals or other thermoplastics using heat, high temperature, or high pressure.

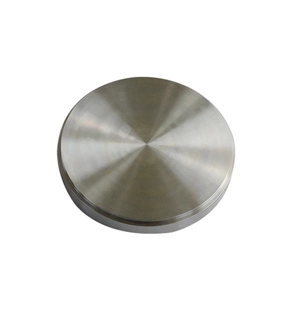

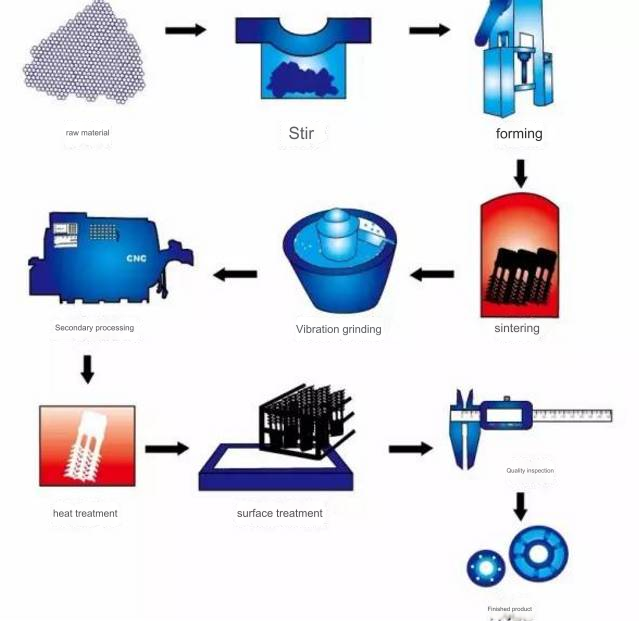

5.Powder Metallurgy

Powder metallurgy is a process technology that produces metal materials, composites, and various types of products by using metal powders (or mixtures of metal and non-metal powders) as raw materials, through forming and sintering.

Basic Process Flow:

Advantages:

Most refractory metals and their compounds, pseudo-alloys, and porous materials can only be manufactured using powder metallurgy methods.

Saves metal and reduces product cost.

No material contamination, making it possible to produce high-purity materials.

Ensures the correctness and uniformity of material composition.

Suitable for producing large quantities of products with the same shape, significantly reducing production costs.

Disadvantages:

Consideration of part size in the absence of mass production.

Higher mold costs compared to casting molds.

Production Range:

Powder metallurgy technology can directly produce porous, semi-dense, or fully dense materials and products, such as oil-impregnated bearings, gears, cams, guide rods, and tools.

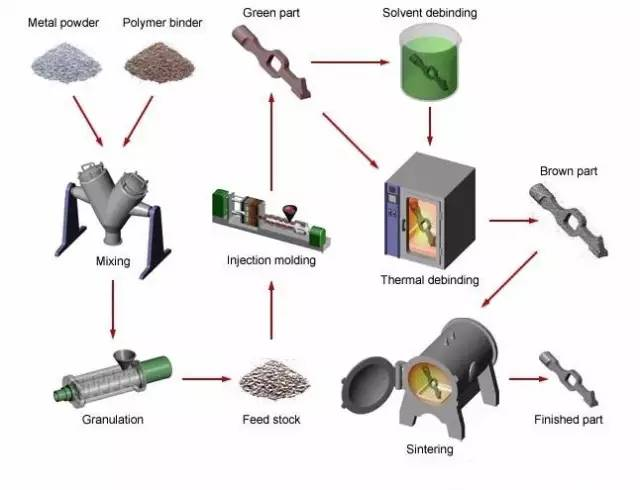

6.Metal Injection Molding

MIM (Metal Injection Molding) is a process where metal powder is mixed with a binder and then injection molded into a shape. The selected powder is mixed with the binder, granulated, and then injection molded into the desired shape.

MIM Process Flow:

The MIM process is divided into four distinct steps (mixing, molding, debinding, and sintering) to produce parts, with surface treatment applied as needed based on product characteristics.

Technical Characteristics:

Complex parts formed in one step.

Good surface quality, low scrap rate, high production efficiency, and easy automation.

Low requirements for mold materials.

Technical Core:

The binder is the core of MIM technology. Adding the right amount of binder enhances powder fluidity, making it suitable for injection molding and maintaining the basic shape of the molded parts.

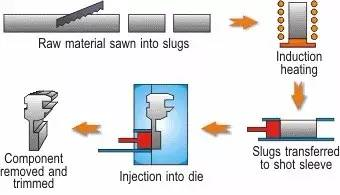

7. Metal Semi-Solid Forming

Semi-solid forming uses the unique rheology and slurry properties of non-dendritic semi-solid metals (Semi-Solid Metals, SSM) to control the quality of castings.

Semi-Solid Forming Types:

Rheoforming

Thixoforming

Technical Characteristics:

Reduces liquid forming defects, significantly improving quality and reliability.

Lower forming temperature than full liquid forming, greatly reducing thermal shock to molds.

Can manufacture alloys that conventional liquid forming methods cannot.

Applications:

Currently used successfully in the manufacture of master cylinders, steering system parts, rocker arms, engine pistons, wheel hubs, transmission system parts, fuel system parts, air conditioning parts, as well as in aviation, electronics, and consumer products.

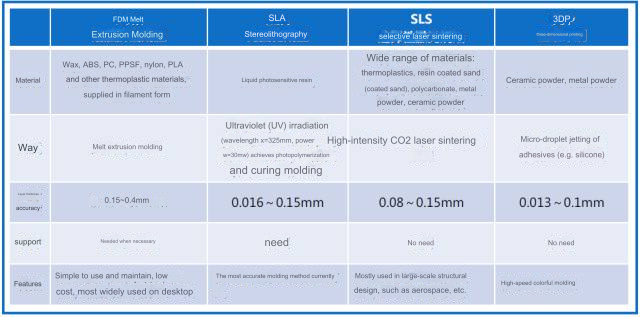

8. 3D Printing

3D printing, a type of rapid prototyping technology, is a method of constructing objects by layer-by-layer printing of materials such as powdered metals or plastics based on digital model files.

Comparison of 3D Printing Technologies:

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский