Thank you for your

attention on Yesheng !

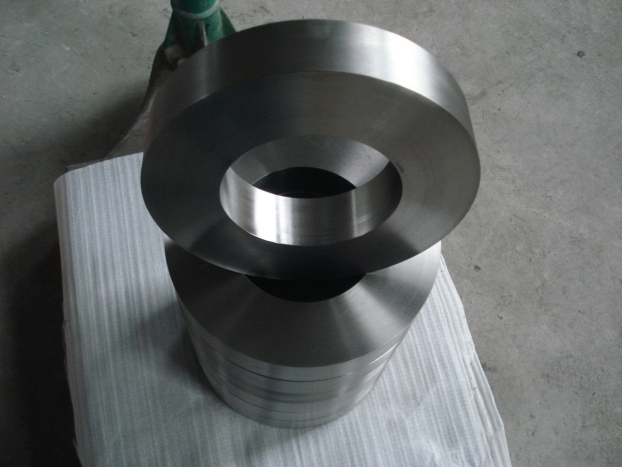

Effective Methods to Eliminate Widmanstätten Structure During Titanium Alloy Forging

The formation of Widmanstätten structure during titanium alloy forging is a critical issue that must be addressed as it can reduce the material's plasticity and toughness. To effectively eliminate this structure, the following measures can be taken:

1、Control of Forging Temperature custom titanium products have a narrow forging temperature range, and forging should be conducted in the α+β phase region to ensure good plasticity without causing significant grain growth. For example, the β-transformation temperature (Tβ) for TA1/TA2 titanium alloy is between 885°C and 900°C, so the forging temperature range should be set between 800°C and 900°C.

2、Optimization of Forging Process Adopting appropriate forging processes, such as drawing and upsetting techniques, can help prevent the formation of Widmanstätten structure. For example, flattening the titanium billet followed by upsetting increases the cross-sectional area, which prepares for subsequent broadening. This ensures regular metal flow, making size control easier and reducing the occurrence of Widmanstätten structure.

3、Heat Treatment A two-step method involving heat treatment in the β phase region and hot compression in the α phase region can refine the grain structure and eliminate Widmanstätten structure. This process leverages the abundant defects in the Widmanstätten structure, utilizing geometric dynamic recrystallization to refine grains and grain boundary sliding to achieve rigid grain rotation, effectively weakening the "microtexture bands" defects present in the original structure.

4、Control of Cooling Rate Controlling the cooling rate is essential to avoid the formation of Widmanstätten structure. During the forging process, the cooling rate of the forged piece should be controlled to prevent rapid cooling that may lead to structural transformation.

5、Post-Forging Heat Treatment For already formed Widmanstätten structure, subsequent heat treatment processes such as normalizing, annealing, or double-normalizing can be used to eliminate it.

6、Superplastic Forming In certain cases, superplastic forming technology can be applied, where deformation is performed at lower temperatures and higher strain rates to refine the grain structure and eliminate Widmanstätten structure.

7、Precise Control of Chemical Composition Optimizing the chemical composition of titanium alloys through precise control can improve their microstructure and reduce the formation of Widmanstätten structure.

8、Use of Advanced Manufacturing Processes Advanced processes such as selective laser melting can be used to manufacture parts with specific lattice structures. The stress generated during the cooling process can be alleviated through subsequent heat treatment.

By applying these measures comprehensively, the Widmanstätten structure can be effectively prevented and eliminated during titanium alloy forging, thus improving the quality and performance of the forged components.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский