Thank you for your

attention on Yesheng !

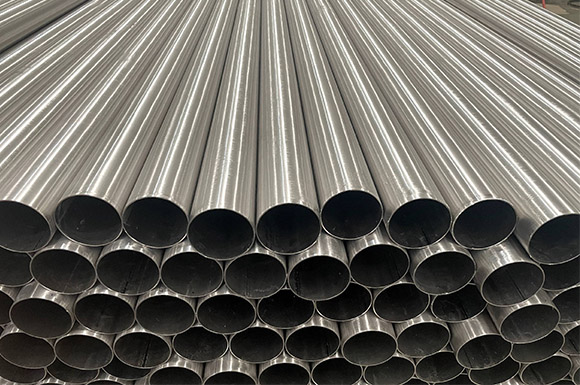

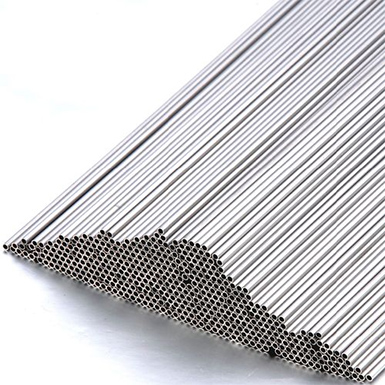

Five Major Properties and Seven Applications of Titanium Tubes

Titanium alloy tubes, made from titanium alloys, possess high mechanical properties, excellent stamping performance, and can be welded in various forms, with weld joint strength reaching 90% of the base metal strength. They also have good machinability. Titanium tubes exhibit high corrosion resistance to chlorides, sulfides, and ammonia. In seawater, titanium's corrosion resistance surpasses that of aluminum alloys, stainless steel, and nickel-based alloys. Titanium also has strong resistance to water impact.

Properties of Titanium Tubes

1、Ductility: 、Titanium tubes are highly ductile, with high-purity titanium tubes having an elongation of 50-60% and a reduction of area of 70-80%. Although high-purity titanium tubes have low strength, the mechanical properties of commercially pure titanium can be significantly enhanced by adding a small amount of impurities and alloying elements, making their strength comparable to that of high-strength materials. This means that even with just a small amount of interstitial impurities and other metallic impurities, commercially pure titanium tubes can achieve both high strength and adequate ductility.

2、High Specific Strength: The specific strength (strength-to-weight ratio) of industrially pure titanium tubes is very high among structural metals. Their strength is comparable to steel, but they weigh only 57% as much as steel.

3、Heat Resistance: Titanium tubes exhibit excellent heat resistance, maintaining good strength and stability even in atmospheres up to 500°C.

4、Low-Temperature Performance: Titanium tubes also have good low-temperature performance, retaining high impact strength even at ultra-low temperatures of -250°C, and they are resistant to high pressure and vibration.

5、Corrosion Resistance: Titanium tubes have strong corrosion resistance due to their high affinity for oxygen, which allows them to form a dense oxide film on their surface, protecting the titanium from corrosion by various media. Therefore, titanium exhibits excellent stability in acidic, alkaline, neutral salt solutions, and oxidizing media, surpassing the corrosion resistance of existing stainless steels and other non-ferrous metals.

Specific Applications of Titanium Tubes

Titanium tubes are lightweight, strong, and have excellent mechanical properties, making them widely used in heat exchange equipment such as tube-type heat exchangers, coil-type heat exchangers, serpentine heat exchangers, condensers, evaporators, and pipelines. Specific applications include:

1、Chemical Equipment: The types of chemical equipment have evolved from small and single-purpose to large and diversified. According to chemical industry estimates, the application of titanium tube equipment has expanded from the initial soda ash and caustic soda industries to the entire chemical industry. The annual usage of titanium tubes in the chemical industry is expected to exceed 1,500 tons. Since the 1970s and 1980s, vacuum salt manufacturing enterprises in China have gradually adopted titanium tube metal materials for equipment production, significantly improving the corrosion resistance of the equipment.

2、Petroleum Refining: During petroleum refining, sulfides, chlorides, and other corrosive agents in the products and cooling water pose serious corrosion risks, particularly to the overhead condensers of vacuum and atmospheric towers in the low-temperature light oil sections. The corrosion of equipment has become a major issue in the refining industry. In recent years, countries like the United States and Japan have introduced titanium tube equipment into these high-corrosion areas, achieving excellent results.

3、Automotive Industry: Titanium tubes have been used in racing cars for many years. Their lightweight and high-strength properties have long attracted the attention of automobile manufacturers. Nowadays, almost all racing cars use titanium tubing. Japan's automotive industry consumes over 600 tons of titanium annually, and with the global development of the automotive industry, the use of titanium tubes in vehicles is rapidly increasing.

4、Sports Equipment: Titanium tubes, with their high strength, light weight, and corrosion resistance, are ideal materials for making high-quality sports equipment such as iron clubs, golf clubs, and bicycle frames.

5、Medical Field: Titanium tubes have excellent biocompatibility and are less likely to cause rejection reactions in the human body. Coupled with their superior corrosion resistance and strength, they have gradually become the preferred material in the medical field. Titanium tubes are used to manufacture artificial joints, dental implants, cranial repair materials, internal stents, and other medical devices.

6、Aerospace: Titanium tubes possess excellent corrosion resistance and fatigue strength, making them suitable for producing various structural components and parts, such as engine components, cylinders, landing gear, seat frames, oxygen tanks, and rocket sealing structures.

7、Marine Engineering: In the deep-sea environment, where water pressure is extremely high, the corrosion resistance of titanium tubes becomes essential for marine engineering. They are widely used in producing submarine pipelines, subsea oil wells, support structures for offshore wind turbines, and marine biological resource survey equipment.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский