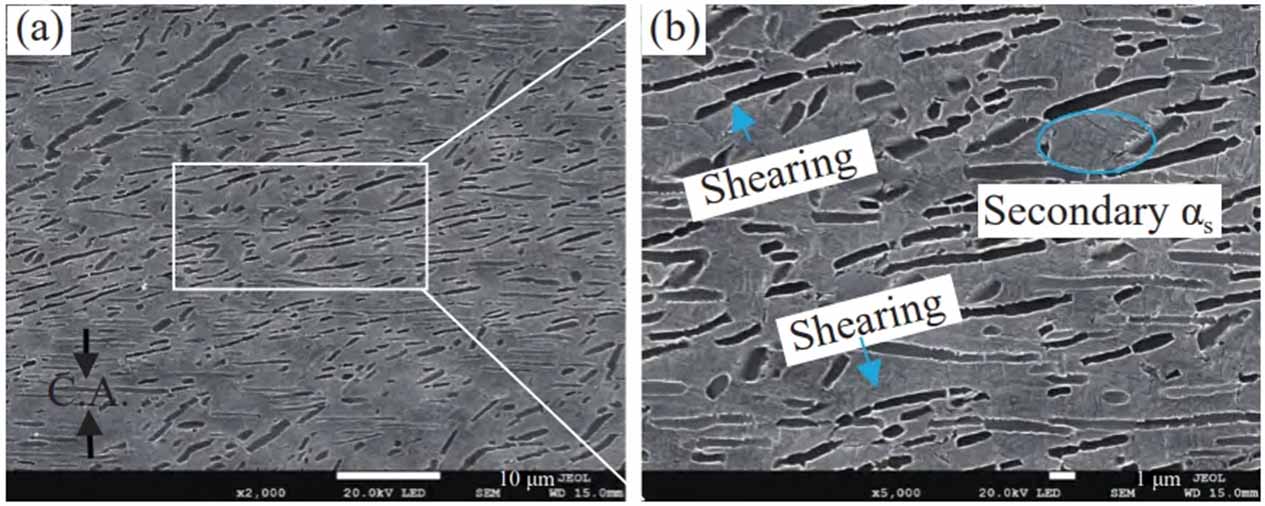

Thank you for your

attention on Yesheng !

Thermal Deformation Behavior of SP700 Titanium Alloy

Titanium alloys are known for their low density, high specific strength, and excellent comprehensive properties, making them ideal for reducing the weight of structural components in aerospace, marine, and other fields. However, during processing, titanium alloys often face challenges such as high deformation resistance and significant springback after forming. Superplastic forming (SPF) emerges as a promising hot processing technology that can form complex-shaped parts in a single step, improving material utilization and reducing production costs.

SP700 titanium alloy is favored for its excellent superplasticity and mechanical properties and has been included in the U.S. aerospace material specifications, with successful applications in aerospace body materials. The alloy is predominantly used in sheet form for superplastic forming, typically produced by multi-pass two-phase region hot rolling to obtain thin SP700 titanium sheets.

In this study, hot compression deformation experiments were conducted to investigate the flow behavior of SP700 titanium alloy, exploring the effects of deformation process parameters on the alloy's microstructure and the spheroidization behavior of lamellar structures during thermal deformation. This provides a theoretical basis for formulating the hot deformation process for SP700 titanium alloy.

1. Experimental Materials and Methods

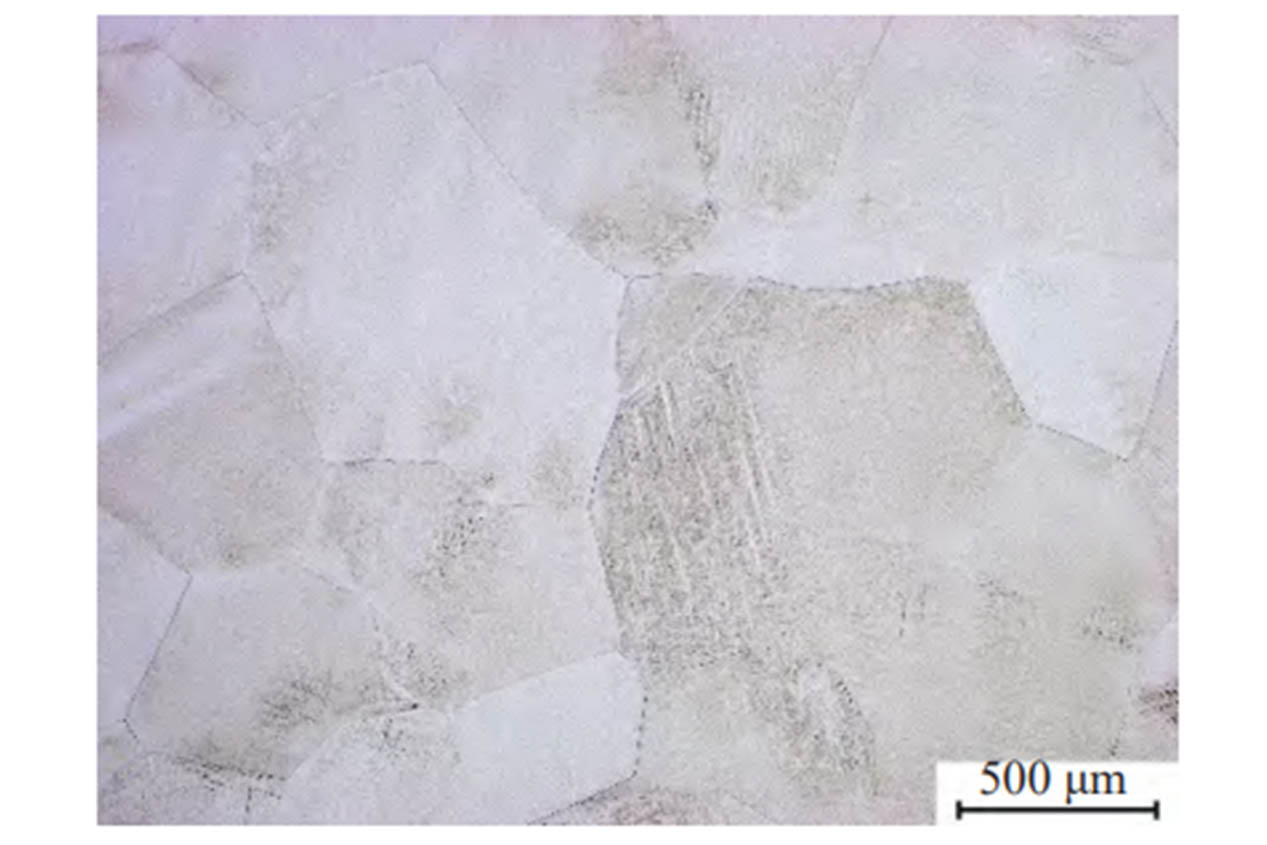

The experimental material used was a rolled SP700 titanium alloy plate with a thickness of 22 mm, and its chemical composition is listed in Table 1. The phase transition point of the alloy was determined to be 910°C using metallographic methods. The original plate was subjected to water quenching after holding at 940°C for 30 minutes, resulting in a quenched structure primarily composed of fine acicular martensite with an average prior β grain size of approximately 615 μm, as shown in Figure 1

Fig.1 Water-quenched microstructure of SP700 titanium alloy

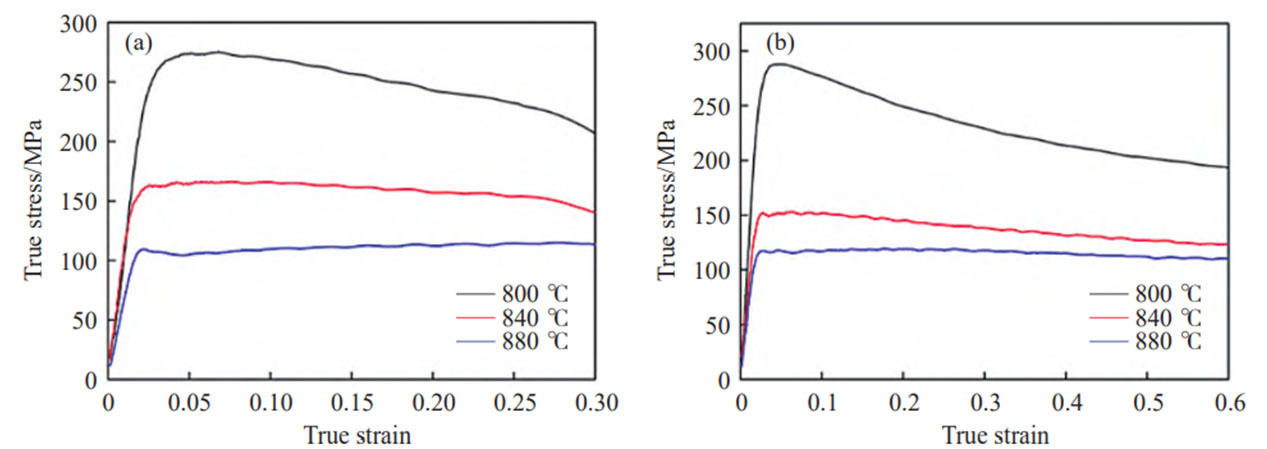

Table 1 Chemical composition of SP700 titanium alloy%

The quenched alloy was then subjected to hot compression simulation tests. The sample size was ϕ8 mm × 12 mm, with the height direction parallel to the plate's normal direction. The tests were conducted on a Gleeble3800 thermal simulation machine. Before compression deformation, graphite sheets were used to lubricate both ends of the sample to reduce uneven deformation caused by friction. The testing temperatures were 800, 840, and 880°C, with strain rates of 1, 5, and 10 s⁻¹, and compression deformation amounts of 30% and 50%. The samples were heated to the deformation temperature at a rate of 10°C/s, held for 5 minutes, and then subjected to compression deformation. After deformation, the samples were quenched in water to preserve the high-temperature deformation microstructure.

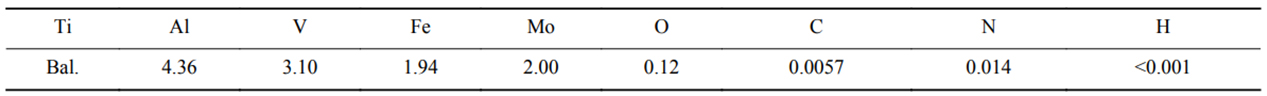

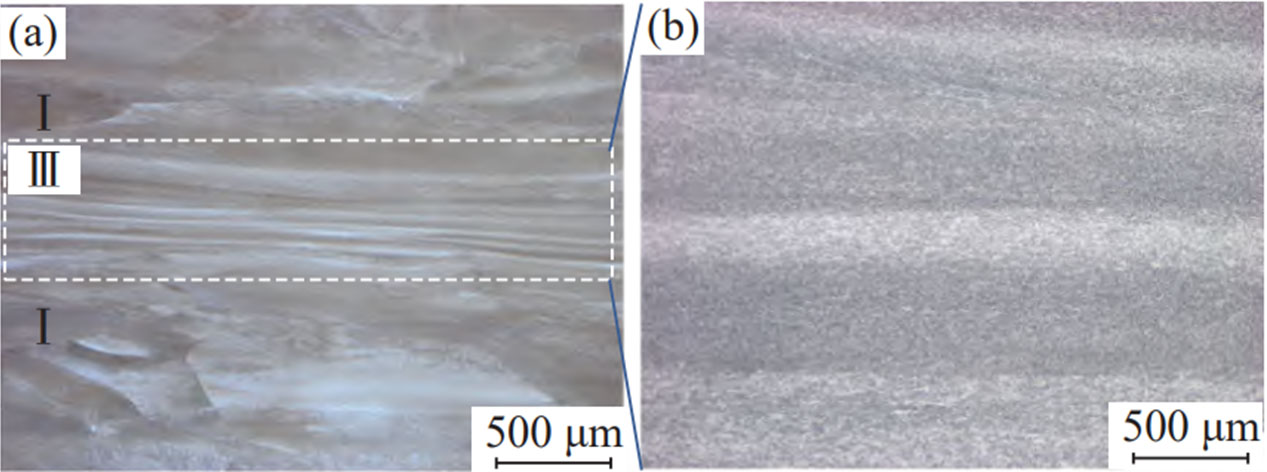

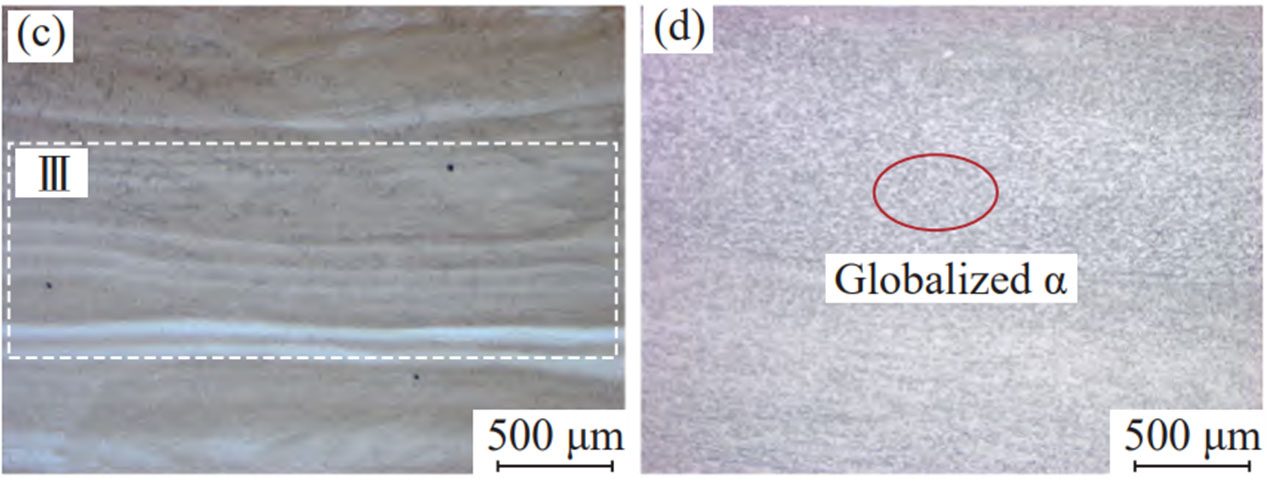

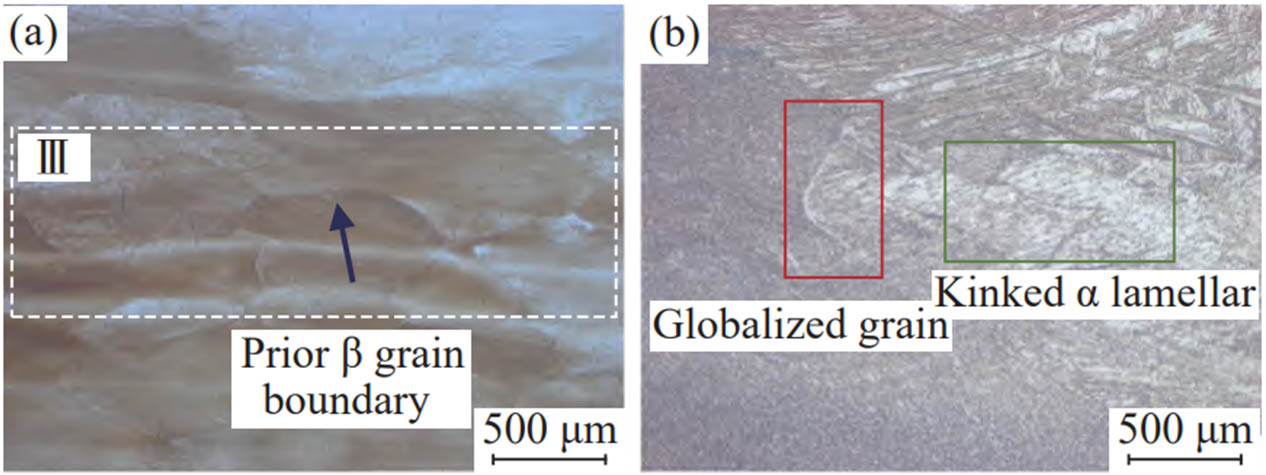

The compressed samples were sectioned parallel to the compression axis for microstructural observation and analysis, as shown in Figure 2. The figure labels σ as the stress, indicating the direction of stress loading. The compression deformation sample mainly comprised three regions: hard-to-deform region I, free deformation region II, and large deformation region III. This study focuses on the impact of deformation conditions on the microstructure, primarily examining the large deformation region III. The observation surfaces of the samples were ground with 240-5000# SiC water abrasive paper, electropolished at room temperature and 65V in a solution of 5% HClO4 + 95% CH3COOH by volume, and then etched using Kroll’s reagent (2 mL HF, 8 mL HNO3, and 82 mL H2O). Microstructure analysis was conducted using an Axiovert 200 MAT optical microscope (OM), a JEOL JEM-7900F scanning electron microscope (SEM), and electron backscatter diffraction (EBSD) at an accelerating voltage of 20 kV.

Fig.2 Schematic diagram of the observation positions after compression

2. Results and Discussion

2.1 Thermal Deformation Behavior

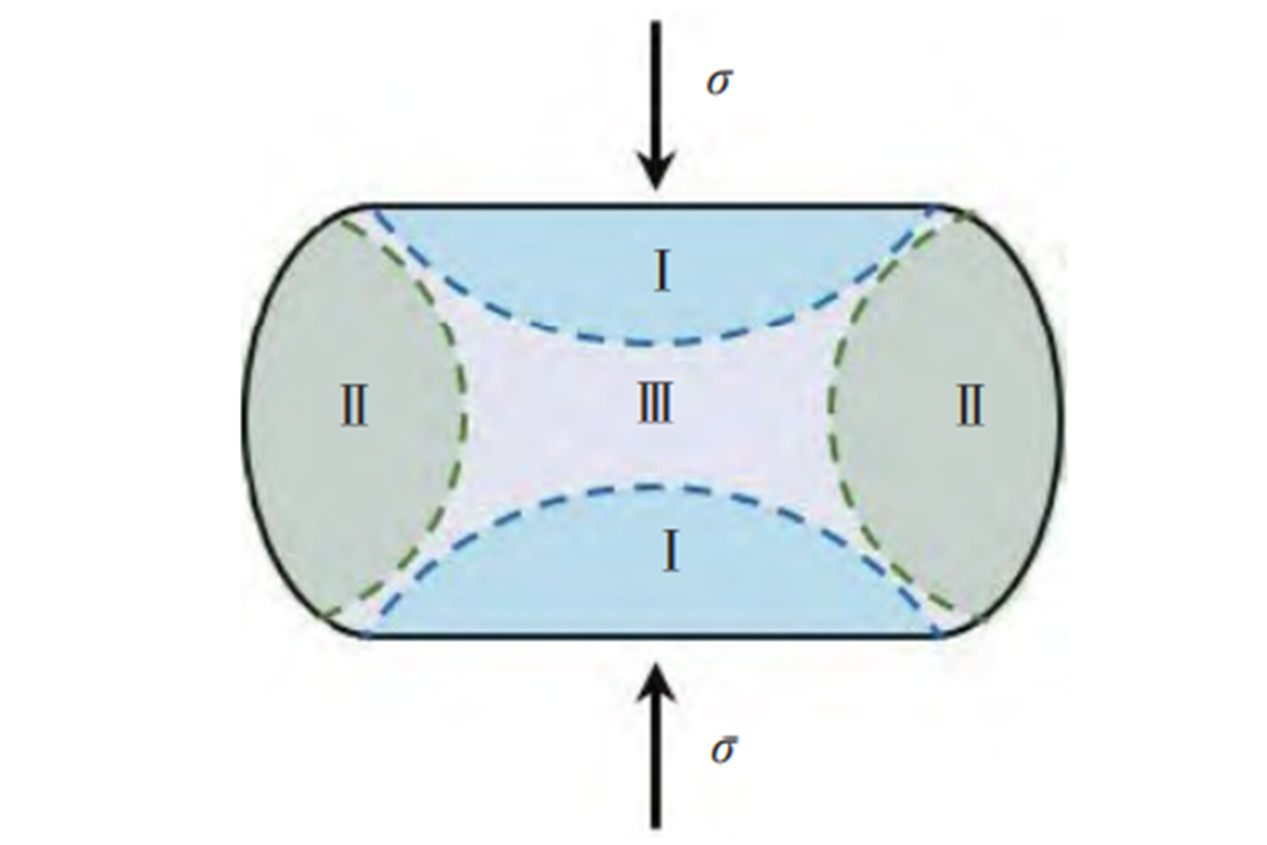

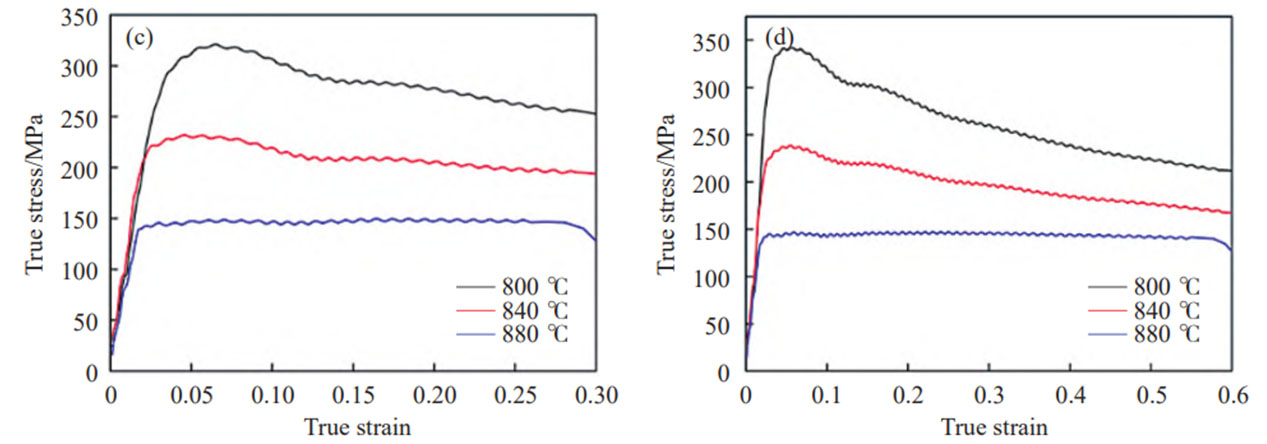

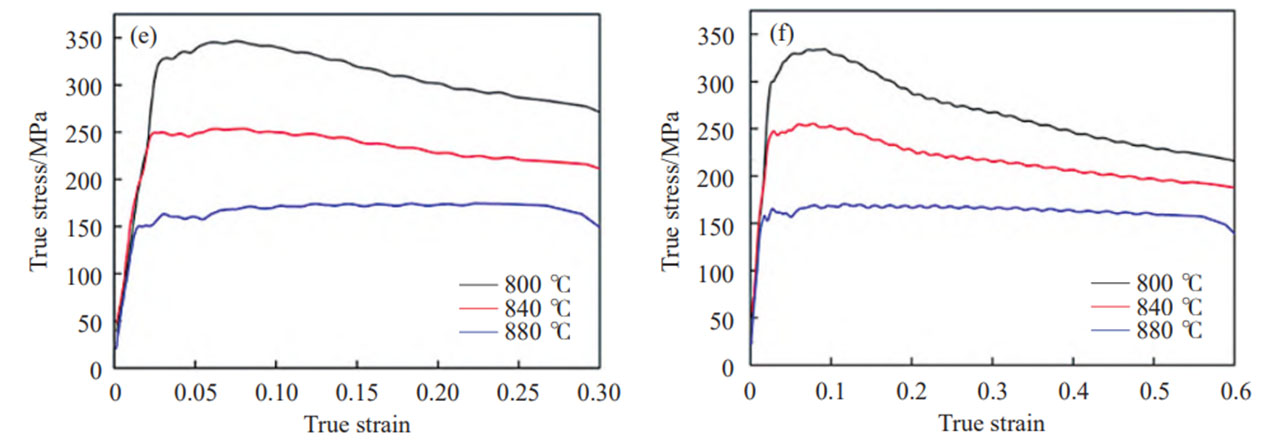

Figure 3 shows the true stress-true strain curves of SP700 titanium alloy under different deformation parameters during hot compression. It can be seen that in the initial stage of compression deformation, as the strain increases, the flow stress of the alloy rapidly rises. This is primarily due to the rapid multiplication of dislocations within the alloy during the initial stage of deformation, with the rate of dislocation multiplication surpassing the rate of dislocation annihilation caused by movement, leading to work hardening of the alloy. Once the flow stress reaches a peak value, with further increase in compression deformation, the true stress-true strain curves exhibit different patterns. At 800°C, the stress gradually decreases and stabilizes after reaching the peak, indicating flow softening. At higher temperatures (840-880°C), the stress remains nearly constant after reaching the peak value, displaying a steady-state flow behavior.

Figure 3 (a) 1 s–1/30%; (b) 1 s–1/50%; (c) 5 s–1/30%; (d) 5 s–1/50% ;(e) 10 s–1/30%; (f) 10 s–1/50%

During the hot deformation of titanium alloys, work hardening due to plastic deformation competes with softening caused by dynamic recovery or dynamic recrystallization, leading to different characteristics in the true stress-true strain curves. In the initial stage of plastic deformation, as the deformation increases, dislocation density rapidly rises and entangles, obstructing dislocation motion and causing an increase in flow stress. With further deformation, the increased dislocation density raises the stored deformation energy within the alloy. When the stored energy reaches the activation energy for dynamic recrystallization, dynamic recrystallization occurs, reducing the dislocation density and causing flow softening. When the hardening due to dislocation multiplication and softening due to dynamic recrystallization balance out, the stress-strain curve exhibits steady-state flow. If softening significantly exceeds hardening, the flow stress drops sharply, showing a pronounced dynamic recrystallization-type curve. Additionally, numerous studies have found that the spheroidization of lamellar or lath structures in titanium alloys can also lead to flow softening. From Figure 3, it is evident that at 800°C, with compression deformation exceeding 50%, the alloy undergoes significant dynamic recrystallization. Under the same strain rate and compression deformation amount, the peak stress of the SP700 titanium alloy decreases with increasing deformation temperature. For a constant deformation temperature and amount, the peak stress of the alloy increases with increasing strain rate, due to rapid dislocation multiplication and increased dislocation density.

2.2 Influence of Deformation Parameters on Alloy Microstructure

2.2.1 Deformation Temperature

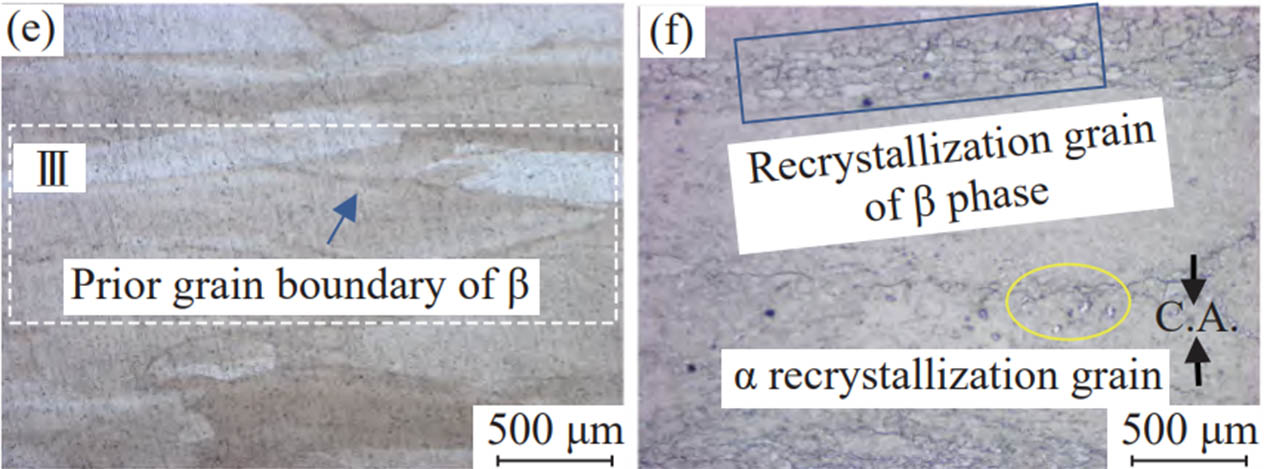

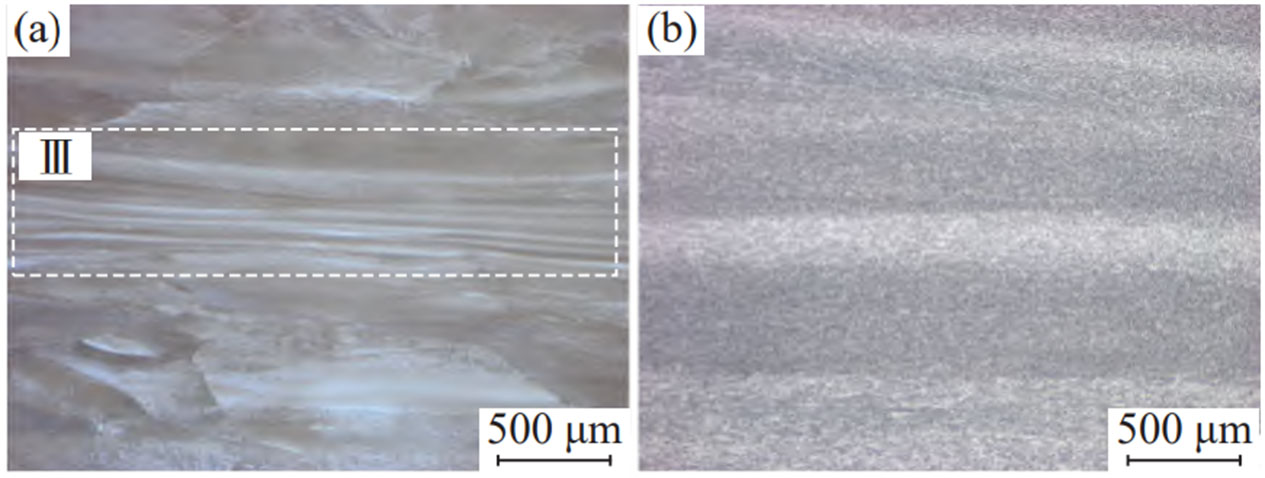

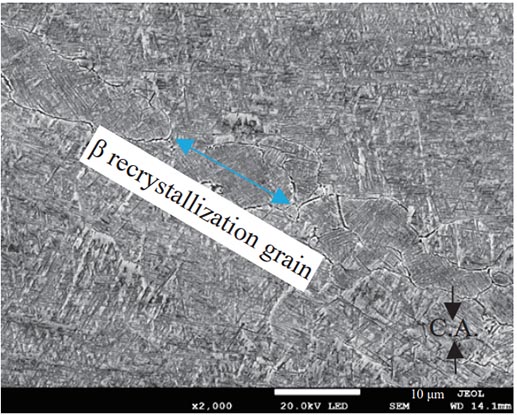

Figure 4 shows the microstructure of SP700 titanium alloy compressed at different temperatures (800-880°C) under a strain rate of 1 s⁻¹ and a compression deformation amount of 50%. In the two-phase region after compression deformation, the microstructure of SP700 titanium alloy primarily consists of α lamellae and a small amount of residual β phase. As shown in Figures 4(a), (c), and (e), deformation temperature significantly affects the microstructure of SP700 titanium alloy. Compared with the original structure (Figure 1), the original β grains elongate perpendicular to the compression direction after compression deformation. At 800°C and 840°C, the original β grain boundaries disappear, and the α lamellae undergo spheroidization. With increasing deformation temperature, the degree of spheroidization of the α lamellae decreases. When the temperature rises to 880°C, the original β grains are retained with clear grain boundaries, and numerous β recrystallized grains are observed at the grain boundaries. This is because after thermal deformation, rapid cooling results in a large degree of supercooling, hindering element diffusion and causing partial original β phase to transform into an oversaturated solid solution with the same crystal structure. As the deformation temperature increases, the degree of spheroidization of the intragranular α lamellae decreases, with only a few recrystallized equiaxed α grains observed after compression deformation at 880°C. This could be due to the β phase having a body-centered cubic structure with more slip systems, leading to dynamic recovery and recrystallization first during deformation, thereby reducing deformation stored energy and decreasing the tendency for α lamellae spheroidization.

Figure 4 (a, b) 800 ℃; (c, d) 840 ℃; (e, f) 880 ℃

2.2.2 Strain Rate

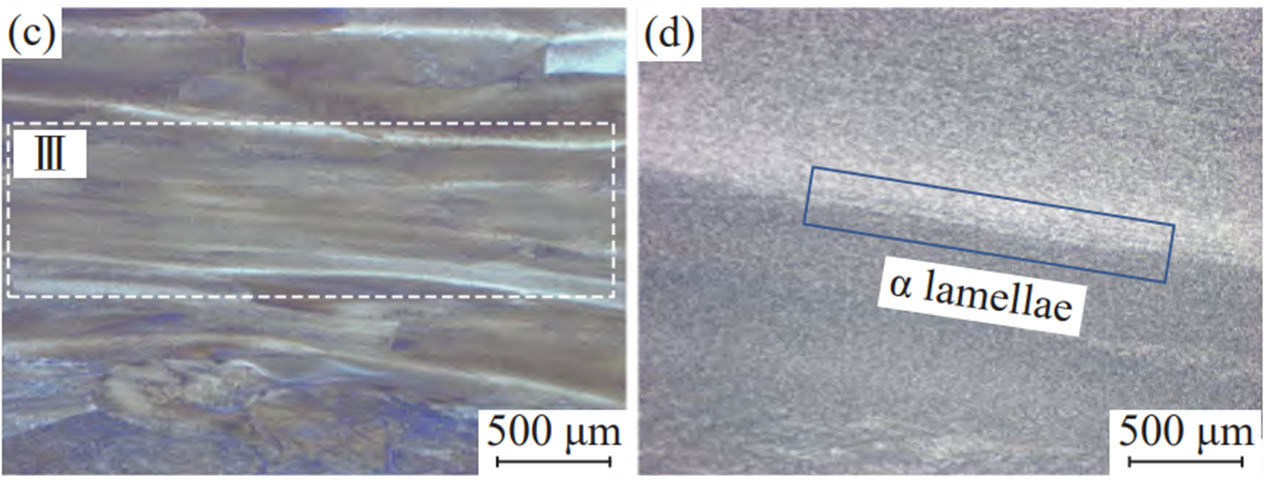

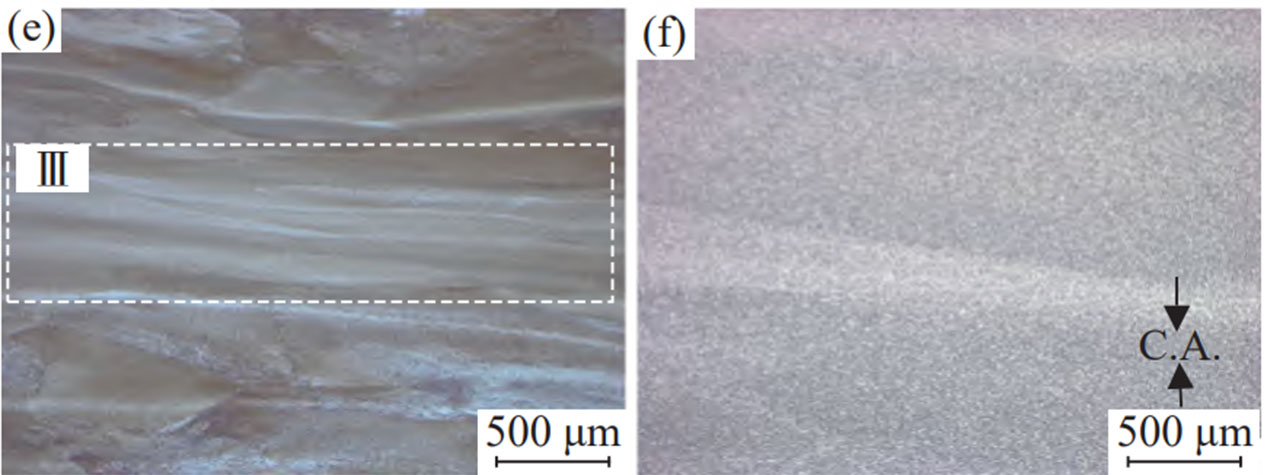

Figure 5 shows the microstructure of SP700 titanium alloy compressed at different strain rates (1-10 s⁻¹) under a deformation temperature of 800°C and a compression deformation amount of 50%. The β grains elongate perpendicular to the compression direction after compression deformation, and the original β grain boundaries become blurred, forming distinct flow lines. As the strain rate increases, the intragranular α lamellae coarsen, fracture, and spheroidize. At strain rates of 1 s⁻¹ or 5 s⁻¹, a few α lamellae with aspect ratios greater than 3 remain in the deformation microstructure, as shown in Figure 5(d). When the strain rate increases to 10 s⁻¹, the extent of fracture and spheroidization of the original β grains and intragranular α lamellae increases, the original β grain boundaries disappear, and significant dynamic recrystallization occurs in the alloy, resulting in a microstructure consisting of recrystallized grains, as shown in Figure 5(f). In titanium alloys, plastic deformation primarily occurs through dislocation movement. With a constant compression deformation amount, increasing the strain rate reduces deformation time, inhibiting grain boundary sliding and diffusion creep, leading to dislocation pile-up at interfaces, thus promoting dislocation slip within grains. Consequently, increasing the strain rate makes α lamellae more susceptible to shear deformation or grain rotation, increasing the degree of lamellae spheroidization. Additionally, the grain boundary defects and dislocations in the original β phase provide numerous nucleation sites for recrystallization, thus increasing the extent of dynamic recrystallization of the β phase with increasing strain rate.

Figure 5 (a, b) 1 s–1; (c, d) 5 s–1; (e, f) 10 s–1

2.2.3 Compression Deformation Amount

Figure 6 shows the microstructure of SP700 titanium alloy at a deformation temperature of 800°C and a strain rate of 5 s⁻¹ under different compression deformation amounts (30% and 50%). As can be seen, after a 30% compression deformation (Figures 6(a) and (b)), the original β grains are flattened, but the grain boundaries remain clearly visible. Additionally, a significant number of fine recrystallized grains are observed at the β grain boundaries. Within the grains, the α lamellae exhibit bending, and some α lamellae show undulations at the interfaces, indicating that dynamic recrystallization has begun to occur even at smaller deformation amounts. When the deformation amount is increased to 50% (Figures 6(c) and (d)), the β grain boundaries become almost linear, and the α lamellae within the grains undergo fragmentation and spheroidization, with a further increase in the degree of recrystallization.

Figure 6 (a, b) 30%; (c, d) 50%

2.3 Spheroidization Behavior of Lamellar Structure in SP700 Titanium Alloy

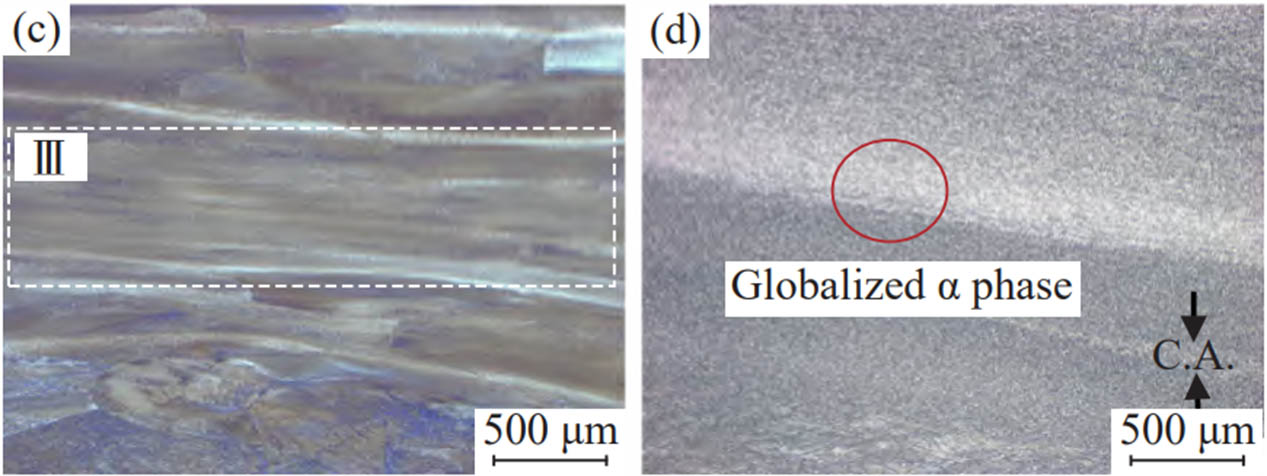

Figure 7 shows the microstructure of SP700 titanium alloy after hot compression deformation at 800°C. The figure indicates that, following the compression deformation, the compressive stress caused the α lamellae to break and rotate perpendicularly to the compression direction. Specifically, the α lamellae that were perpendicular to the compression direction (as shown in region A of Figure 7(a)) exhibited interface undulations, leading to unstable dihedral angles at the boundaries. To reduce surface tension, elemental diffusion at high temperatures caused the β phase to wedge into the α lamellae, leading to the fragmentation of the α lamellae and subsequent spheroidization under high-temperature conditions (as illustrated in Figure 7(b)). For the α lamellae parallel to the compression direction (as shown in region B of Figure 7(a)), significant shape changes occurred. During compression deformation, the lamellar structure underwent bending and twisting under compressive stress, storing significant strain energy within the alloy. This led to the formation of sub-grain boundaries within the lamellar α phase, and the α/β interface rotated under stress, eventually causing the lamellae to break apart.

Figure 7 Microstructure of SP700 titanium alloy subjected to 800 ℃/1 s–1/30% hot compression deformation. (a) Low magnification; (b) High magnification

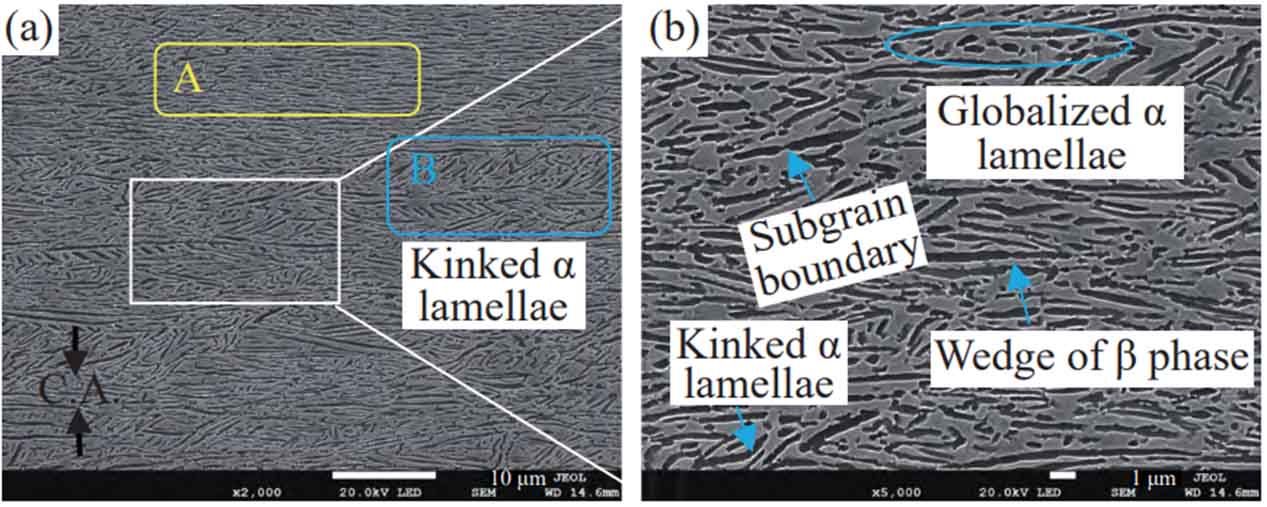

Figure 8 depicts the microstructure of SP700 titanium alloy after hot compression deformation at 840°C. Similar to the behavior at 800°C, the interface of the α lamellae was disrupted and underwent separation during compression at 840°C. However, with the increase in deformation temperature, the α lamellae thickened, and partial dissolution of the α phase was observed. Upon cooling following compression deformation, secondary α phase (αs) precipitated, as shown in Figure 8(b).

Figure 8 Microstructure of SP700 titanium alloy subjected to 840 ℃/1 s–1/30% hot compression deformation. (a) Low magnification; (b) High magnification

When the deformation temperature was raised to 880°C, the microstructure differed significantly from that observed at 800°C and 840°C. As shown in Figure 9, there was little to no spheroidized α phase present at 880°C. As previously mentioned, the phase transformation temperature for the alloy under study is 910°C, suggesting that deformation-induced phase transformation may occur during hot deformation, altering the phase morphology within the alloy. Figure 9 shows that post-880°C deformation, dynamic recrystallization of β grains dominated, with numerous recrystallized β grains forming a "necklace-like" structure at the grain boundaries. Similar microstructural changes have been observed in the hot deformation of Ti-6242S alloy.

Fig.9 Microstructure of SP700 titanium alloy deformed at 880 ℃/1 s–1/30%

3、 Conclusions

1.The high-temperature flow behavior of SP700 titanium alloy is closely related to deformation temperature, strain rate, and compression deformation. During compression deformation at high temperatures (840–880°C), the alloy exhibits steady-state flow characteristics. In contrast, at lower temperatures (800°C) with a compression deformation of 50%, the alloy displays dynamic softening characteristics.

2.Under deformation conditions of 800–880°C, strain rates of 1–10 s⁻¹, and compression deformation of 30%–50%, the primary microstructural changes in SP700 titanium alloy during hot compression deformation are the spheroidization of the α lamellae and the recrystallization of the β phase. As the deformation temperature decreases and the strain rate increases, the degree of spheroidization of the α lamellae increases. Additionally, a larger amount of compression deformation promotes the occurrence of dynamic recrystallization in the alloy.

3.After high-temperature compression deformation, continuous orientation differences develop within the α lamellae perpendicular to the compression axis, causing undulations at the interface and forming unstable dihedral angles. Within the α lamellae parallel to the compression axis, discontinuous orientation differences emerge, creating new α/α interfaces. The β phase wedges into the α lamellae at the dihedral angles or the new α/α interfaces, leading to the fracture and separation of the lamellae, which subsequently undergo spheroidization under high-temperature conditions.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский