Thank you for your

attention on Yesheng !

Investigating Titanium Ingots: Unveiling Properties and Characteristics

Unraveling the Intrinsic Properties of Titanium Ingots

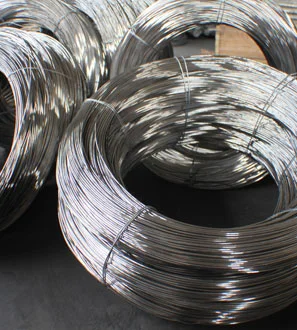

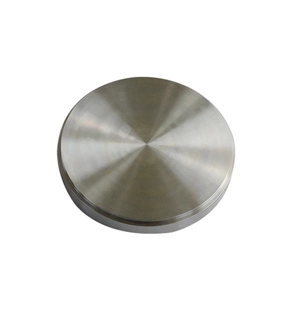

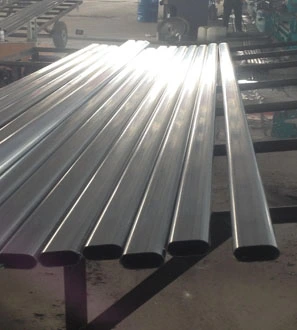

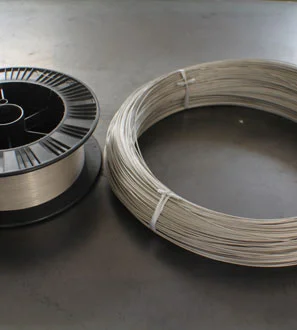

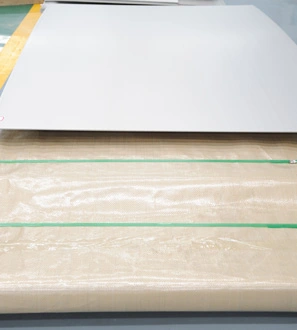

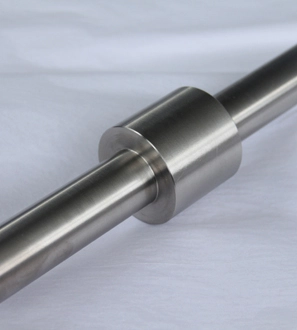

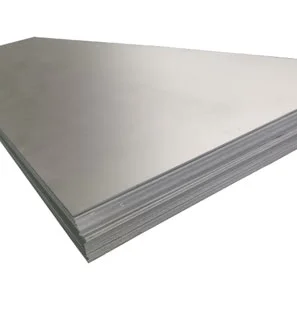

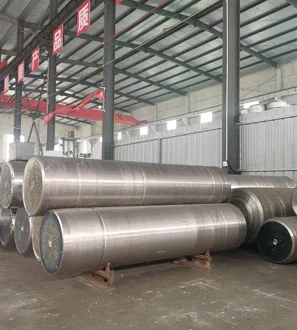

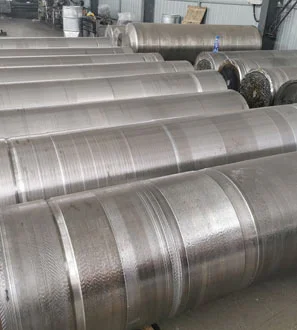

Titanium ingots, the fundamental building blocks of a myriad of industries, possess a unique set of properties that make them highly sought after. Renowned for their exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility, titanium ingots serve as a preferred material in diverse applications. The low density of titanium, combined with its robustness, makes it a staple in aerospace engineering, medical implants, and various high-performance components. As we delve into the investigation of titanium ingots, a closer look at their intrinsic properties unveils a material that stands as a testament to the remarkable synergy of strength and versatility.

The Versatility Unleashed: Utilizing Titanium Ingots Across Industries

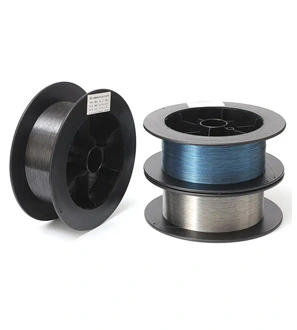

Titanium ingots find their way into an array of industries, each harnessing the metal's unique properties to advance technology and innovation. In aerospace applications, the lightweight yet robust nature of titanium is harnessed to reduce aircraft weight, enhance fuel efficiency, and ensure structural integrity. Medical advancements, on the other hand, benefit from titanium's biocompatibility, making it an ideal choice for implants and surgical instruments. Beyond these core sectors, titanium ingots are also integral in the production of high-performance sports equipment, chemical processing plants, and even consumer electronics. The versatility of titanium ingots lies in their ability to elevate performance across a spectrum of applications, driving progress and pushing the boundaries of what is possible.

Navigating Market Trends: Demand, Innovation, and Global Dynamics

In the dynamic landscape of the titanium market, trends are ever-evolving, influenced by factors such as technological advancements, geopolitical shifts, and environmental considerations. The aerospace industry continues to be a major driver of demand for titanium ingots, with an increasing focus on fuel-efficient and eco-friendly aircraft. Similarly, the medical sector sees sustained growth, driven by the expanding use of titanium in implants and medical devices. Beyond traditional sectors, emerging technologies, such as additive manufacturing, are opening new avenues for titanium ingots, allowing for intricate designs and customized components.

Market trends also reflect a growing emphasis on sustainability, pushing manufacturers to adopt eco-friendly practices in titanium ingot production. Recyclability and closed-loop systems are gaining prominence, aligning with broader global efforts to reduce environmental impact. This shift not only addresses resource concerns but also positions titanium as a material of choice for environmentally conscious industries.

As we conclude our investigation into titanium ingots, it becomes evident that their significance extends beyond the boundaries of any single industry. The properties that make titanium ingots exceptional—strength, lightness, and corrosion resistance—position them at the forefront of material innovation. Market trends underscore the dynamic nature of the titanium industry, with sustained demand from traditional sectors and emerging opportunities driven by technological advancements.

The investigation into titanium ingots unveils a material that is not only integral to present-day technological advancements but also poised to shape the future of manufacturing. From aerospace engineering to medical breakthroughs, titanium ingots continue to be a catalyst for progress, embodying the spirit of innovation and resilience in the ever-evolving landscape of materials science and industry.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский