Thank you for your

attention on Yesheng !

Making Titanium Alloys Stronger—Five Mainstream Metal 3D Printing Technologies

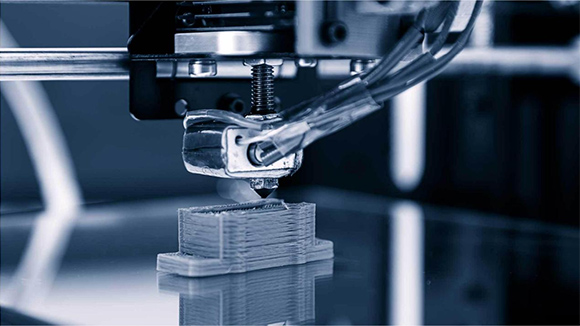

Today, with the rapid development of technology, metal 3D printing, which offers advantages like short-term manufacturing, on-demand production, and rapid prototyping, is turning many impossibilities into realities.

Currently, the mainstream metal 3D printing technologies on the market include the following five: Selective Laser Sintering (SLS), NanoParticle Jetting (NPJ), Selective Laser Melting (SLM), Laser Engineered Net Shaping (LENS), and Electron Beam Selective Melting (EBSM). Below is an introduction to the basic working principles of these five metal 3D printing technologies.

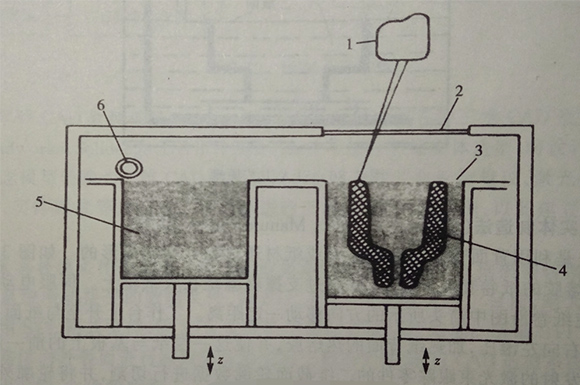

1. SLS - Selective Laser Sintering

Working Principle: A layer of powder material is pre-spread on the work platform. The laser, controlled by a computer, sinters the powder in the solid part according to the contour information of the layer. This process repeats cyclically, building the object layer by layer.

SLS uses an infrared laser as the energy source, and the materials used are mostly powder. During processing, the powder is preheated to just below its melting point, then spread flat by a roller. The laser beam, controlled by a computer, selectively sinters the powder based on the layer's cross-sectional information. After completing one layer, the next is sintered, repeating this process until the 3D part is formed. Finally, the unsintered powder is recovered, and the formed part is removed.

This method is known for its simple manufacturing process, high flexibility, wide material selection, low material cost, high material utilization, and fast forming speed. It is mainly used in the casting industry and can be directly used for rapid mold-making.

2. NPJ - NanoParticle Jetting

Working Principle: Metal is first loaded into the 3D printer in liquid form. During printing, a liquid containing metal nanoparticles is jetted to form the shape. Excess liquid is then evaporated by heating, leaving the metal parts, which are finally sintered at a low temperature to complete the formation.

This method can use ordinary inkjet print heads as tools and does not require external force to remove support structures, as they are melted away. Theoretically, this allows unlimited addition, giving designers greater freedom. In addition to metals, breakthroughs in ceramics technology have extended its applications to dentistry, medicine, and specific industrial fields.

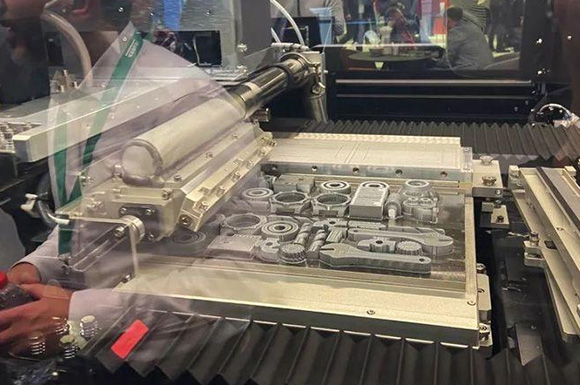

3. SLM - Selective Laser Melting

Working Principle: A high-energy laser beam melts metal alloy powder on the two-dimensional cross-section of the sliced 3D model, printing layer by layer from the bottom up to create metal parts with any complex structure and nearly 100% density.

SLM primarily uses CAD software to design 3D models, exporting them into a format recognizable by slicing software. The model is then sliced and support structures added, with cross-sectional data of the model obtained. Path planning software processes the contour data to generate scanning paths, which are imported into the SLM machine. The machine's control system directs the laser beam to selectively melt metal alloy powder layer by layer according to the scanning path, forming dense 3D metal parts.

SLM's advantages include high material utilization, precise metal part dimensions, and design freedom. Its limitations are high equipment component costs, inability to achieve mass production, and non-standard metal alloy powders required for processing. Therefore, SLM is mainly used in aerospace, biomedical fields, and for manufacturing precious or hard-to-process metal components like titanium and nickel alloys.

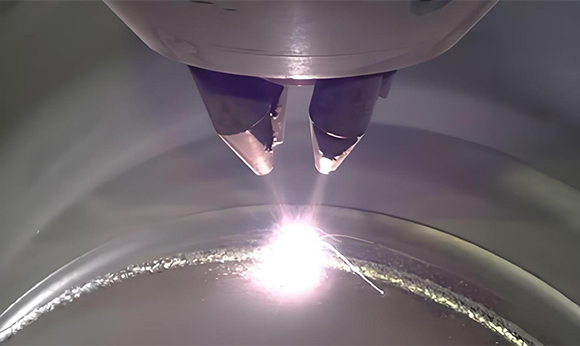

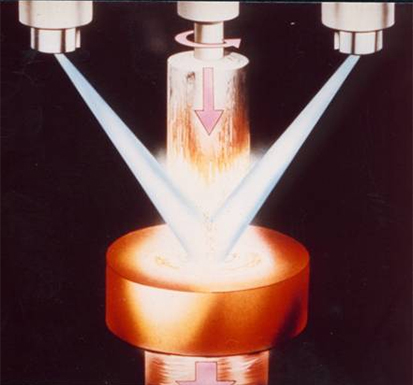

4. LENS - Laser Engineered Net Shaping

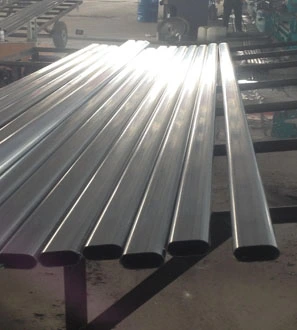

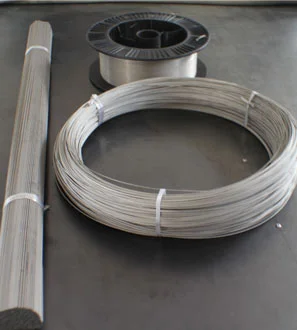

Working Principle: The 3D CAD model of the part is sliced into layers, obtaining the two-dimensional contour data. The contour data is then converted into the motion trajectory of the CNC worktable. Metal powder is fed at a certain rate into the laser focus area, where it is rapidly melted and solidified, building the part layer by layer into a near-net-shape 3D metal part.

LENS enables moldless manufacturing of metal parts, with the resulting parts having dense microstructures and high mechanical properties. It is capable of manufacturing heterogeneous and gradient material parts, as well as processing high-strength metals like titanium alloys.

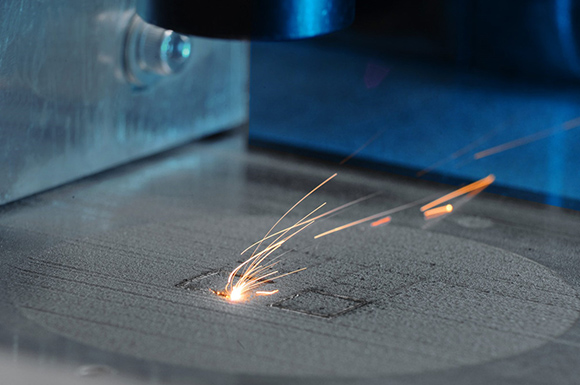

5. EBSM - Electron Beam Selective Melting

Working Principle: The 3D CAD model is first sliced into layers, and the resulting discrete data is input into the forming system. The forming system preheats the material, and the electron beam, guided by the CAD data, melts the pre-spread powder layer on the work platform. After one layer is processed, the work platform lowers by one layer thickness, and the next layer of powder is spread and melted. This process repeats until the 3D part is formed.

EBSM technology offers fast processing speed, high energy efficiency, low vacuum contamination, low residual stress in components, and no reflection issues. It is particularly suitable for the direct forming of reactive, refractory, and brittle metal materials, with broad prospects in aerospace, biomedical, automotive, and mold-making fields.

Prospects of Titanium Alloy 3D Printing Technology

With the development of 3D printing technology, titanium alloy 3D printing will find applications across various aspects of engineering materials. Titanium alloy 3D printing is bound to evolve toward more complex, high-precision, large-scale, and low-cost production. At the same time, 3D printing technology will be applied across various fields, speeding up production, promoting rapid development in manufacturing, and significantly boosting the speed of economic growth in China.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский