Thank you for your

attention on Yesheng !

Titanium and Titanium Alloy Melting Technology

The melting technology of titanium and titanium alloys is a key step in determining the composition and structure of the alloy, which is of great significance for improving the performance of titanium alloys.

1、Vacuum Arc Remelting (VAR)

This is a melting technology conducted in a vacuum, where the metal is melted using the energy of an arc. VAR technology is mainly used for melting reactive and refractory metals, such as titanium, zirconium, molybdenum, and is also suitable for heat-resistant steels, stainless steels, etc. The VAR furnace can produce large-sized and high-tonnage metal ingots, and the metal is not contaminated during the melting process. The structure is uniform, free of shrinkage cavities, and dense. Since inclusions float up during the melting process, some inclusions may concentrate at the ends of the ingot. VAR technology was first used in the early 1950s to remelt high-temperature alloys and has demonstrated superior performance, becoming one of the important methods for remelting high-temperature alloys and special steels.

2、Electron Beam Cold Hearth Melting (EBM)

EBM technology uses an electron beam in a high vacuum as a heat source for metal melting. This technology can provide high-purity metals, especially suitable for melting refractory metals and high-purity metals. In the EBM process, the metal melts and solidifies in a water-cooled copper crucible, effectively preventing contamination of the molten metal by refractory materials, resulting in uniform structure, no shrinkage cavities, and dense steel ingots. EBM technology has unique advantages in eliminating high and low-density inclusions, making it widely used in the melting of titanium and titanium alloys in titanium manufacturing companies.

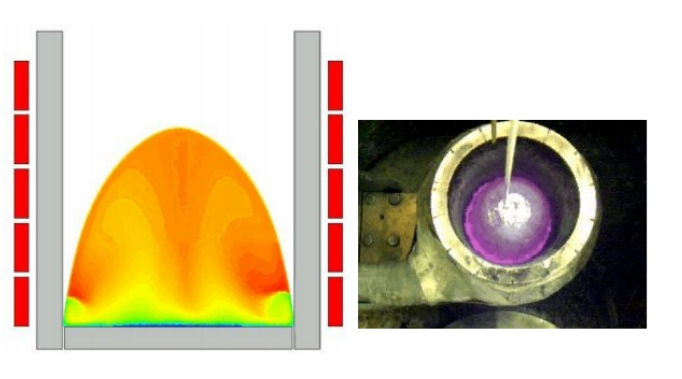

3、Plasma Arc Melting (PAM)

PAM technology uses a plasma arc as the heat source to melt, refine, and remelt metals. Compared with EBM, PAM operates in an inert atmosphere close to atmospheric pressure, which prevents the evaporation of volatile elements, making it suitable for melting highly alloyed and complex titanium alloys. PAM technology features concentrated energy and a slender arc column, providing better stirring during the melting process, which helps to homogenize the alloy composition. PAM technology can effectively eliminate various inclusions in custom titanium products, improving the purity of the alloy.

4、Cold Crucible Induction Melting (CCIM)

This technology uses induction heating to melt in a water-cooled copper crucible. CCIM can melt and process materials without contamination from crucible materials, as the melt and the crucible wall are in a non-contact state, and the crucible wall remains cold, preventing interaction between the melt and the crucible wall. This technology is suitable for melting reactive metals and can provide extremely pure materials.

5、Electroslag Remelting (ESR)

ESR is a refining process that uses the resistive heat of slag for secondary remelting. This technology can produce steel ingots with high purity, dense structure, and uniform composition. In the ESR process, metal droplets pass through a slag pool into the molten metal pool, and due to the cooling effect of the water-cooled mold, the liquid metal solidifies quickly to form an ingot. The variety of products produced by electroslag remelting is wide, and it is applicable to many types of alloy structural steels and high-temperature alloys.

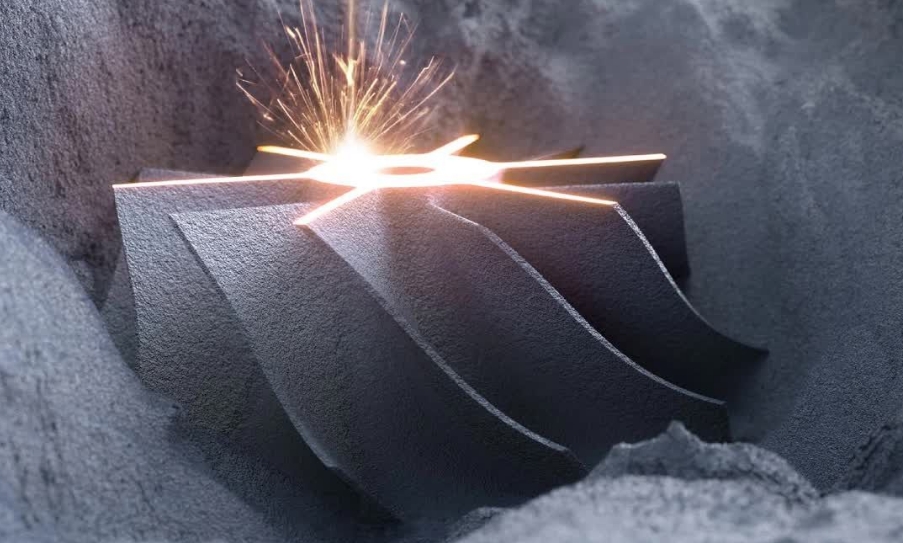

6、Selective Laser Melting (SLM)

SLM is an additive manufacturing technology suitable for the direct production of titanium and titanium alloys. SLM uses a laser as an energy source to scan a bed of metal powder layer by layer according to a 3D CAD model, causing the metal powder to melt, solidify, and metallurgically bond, eventually forming the designed metal part. SLM technology can manufacture metal parts with complex shapes, and the parts have nearly fully dense structures and excellent mechanical properties.

Each melting technology has its unique advantages and application scenarios, and choosing the appropriate melting technology is crucial for improving the performance of titanium alloys. For titanium products such as titanium billet for sale, Yeshengti factory is your first choice. Using advanced melting technology, we manufactures high-quality titanium products.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский