Blog

-

Common Applications of Titanium

13

25.03

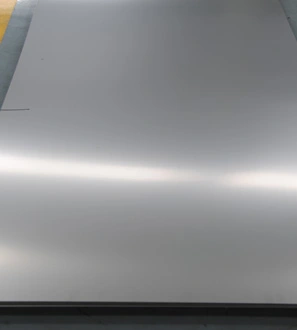

Titanium is an alloying element of steel (ferro-titanium), which reduces the grain size of the steel and acts as a deoxidizer to reduce the oxygen content of the steel; adding titanium to stainless st...

Details

Common Applications of Titanium

13

25.03

Titanium is an alloying element of steel (ferro-titanium), which reduces the grain size of the steel and acts as a deoxidizer to reduce the oxygen content of the steel; adding titanium to stainless st...

Details

-

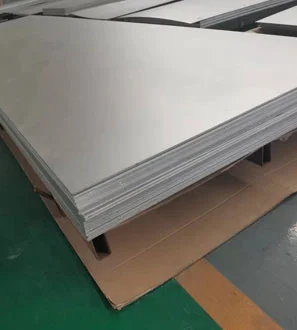

How to lead materials science and technology into a new chapter?

05

25.03

With the continuous progress of material science, new processes for titanium and titanium alloys have become a major highlight in science and technology. These new processes not only enhance the perfo...

Details

How to lead materials science and technology into a new chapter?

05

25.03

With the continuous progress of material science, new processes for titanium and titanium alloys have become a major highlight in science and technology. These new processes not only enhance the perfo...

Details

-

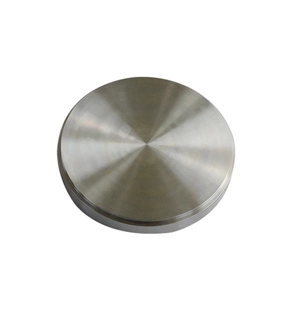

What state is titanium in at room temperature?

04

25.03

Titanium is an important transition metal with the chemical symbol Ti and atomic number 22. Many people may not know much about the state of titanium at room temperature. In this paper, we will discus...

Details

What state is titanium in at room temperature?

04

25.03

Titanium is an important transition metal with the chemical symbol Ti and atomic number 22. Many people may not know much about the state of titanium at room temperature. In this paper, we will discus...

Details

-

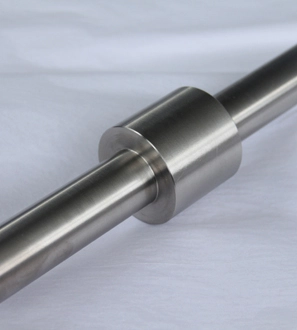

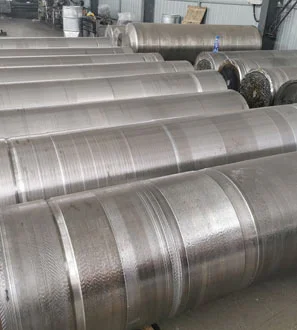

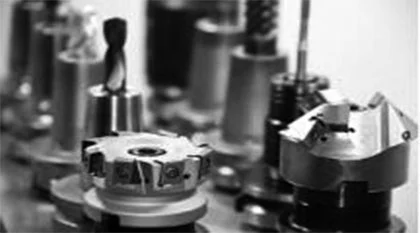

What are Titanium Shafts Used for?

18

25.02

Titanium shafts are integral components in a myriad of industries, renowned for their exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility. These characteristics make titan...

Details

What are Titanium Shafts Used for?

18

25.02

Titanium shafts are integral components in a myriad of industries, renowned for their exceptional strength-to-weight ratio, corrosion resistance, and biocompatibility. These characteristics make titan...

Details

-

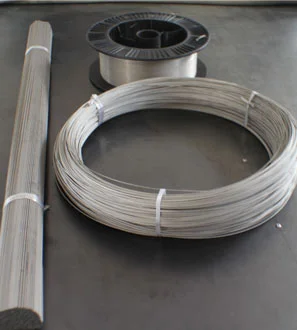

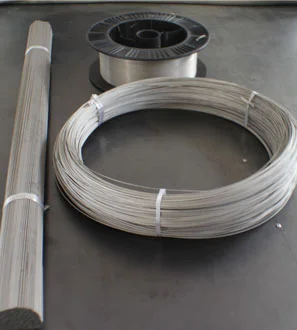

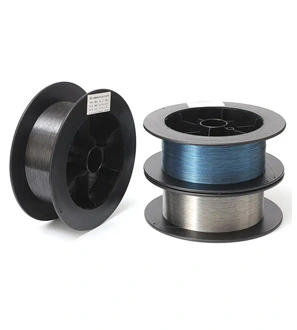

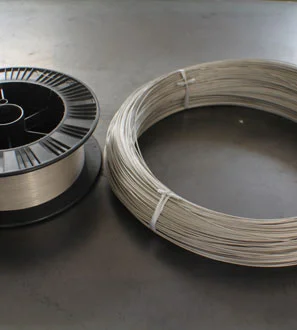

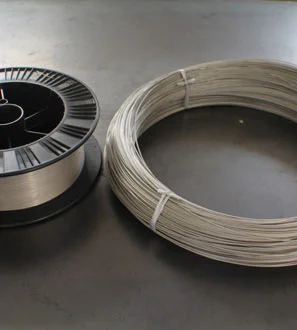

Titanium Filament Introduction

14

25.02

In the world of advanced materials, titanium filament stands out as a revolutionary development. Known for its exceptional strength-to-weight ratio, biocompatibility, and resistance to corrosion, tita...

Details

Titanium Filament Introduction

14

25.02

In the world of advanced materials, titanium filament stands out as a revolutionary development. Known for its exceptional strength-to-weight ratio, biocompatibility, and resistance to corrosion, tita...

Details

-

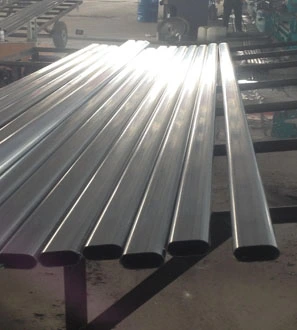

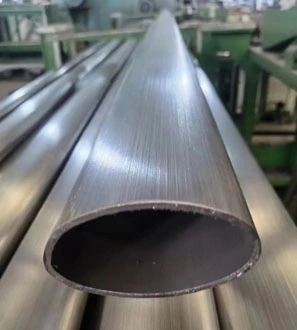

Comprehensive Insights into Custom Titanium Tubes

11

25.02

In an era when advanced engineering and precise material specifications play a crucial role in various industries, custom titanium tubes have carved out a unique niche. These tubes, tailored to meet s...

Details

Comprehensive Insights into Custom Titanium Tubes

11

25.02

In an era when advanced engineering and precise material specifications play a crucial role in various industries, custom titanium tubes have carved out a unique niche. These tubes, tailored to meet s...

Details

-

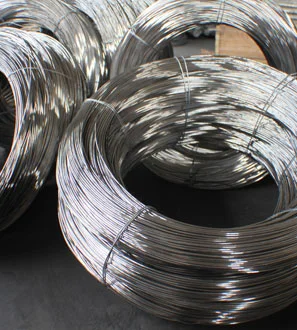

What is 18 Gauge Titanium Wire?

07

25.02

18 gauge titanium wire is a metallic wire made from titanium with a specific diameter typically associated with an 18 gauge measurement, equivalent to 1.024mm. Renowned for its exceptional strength, l...

Details

What is 18 Gauge Titanium Wire?

07

25.02

18 gauge titanium wire is a metallic wire made from titanium with a specific diameter typically associated with an 18 gauge measurement, equivalent to 1.024mm. Renowned for its exceptional strength, l...

Details

-

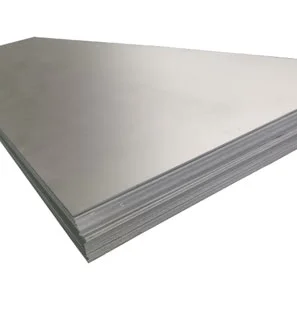

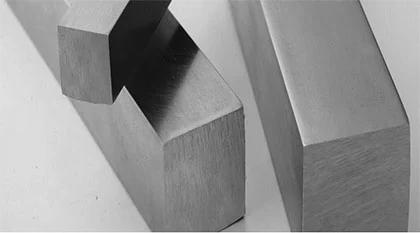

What is Titanium Square Stock?

05

25.02

Titanium square stock represents one of the most versatile materials extensively used in a myriad of industries. Produced from a metal well-regarded for its incredible strength-to-weight ratio, excell...

Details

What is Titanium Square Stock?

05

25.02

Titanium square stock represents one of the most versatile materials extensively used in a myriad of industries. Produced from a metal well-regarded for its incredible strength-to-weight ratio, excell...

Details

-

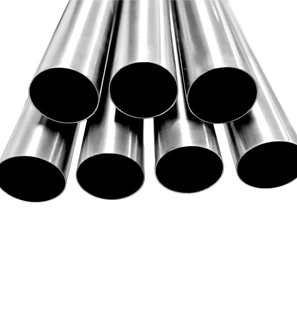

What's the Benefits of Titanium Seamless Tubes?

24

25.01

In the realm of advanced materials, the titanium seamless tube has garnered significant attention for its exceptional properties and wide range of applications. From aerospace engineering to medical d...

Details

What's the Benefits of Titanium Seamless Tubes?

24

25.01

In the realm of advanced materials, the titanium seamless tube has garnered significant attention for its exceptional properties and wide range of applications. From aerospace engineering to medical d...

Details

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский