Thank you for your

attention on Yesheng !

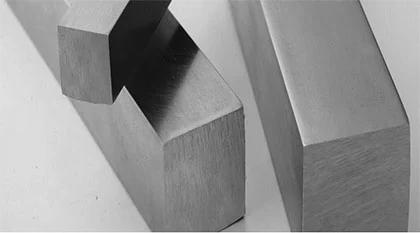

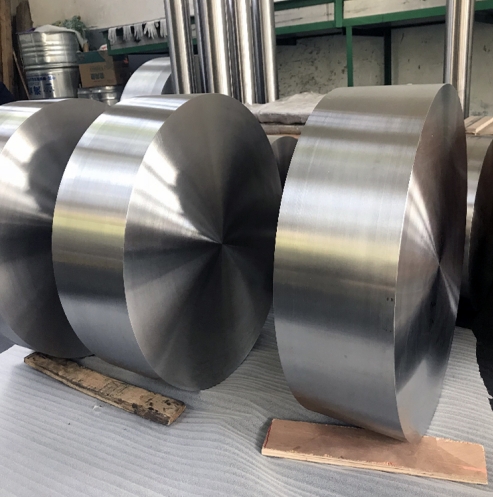

Forging Temperature Requirements for Different Grades of Titanium Alloys

Forging is a critical process in the manufacturing of titanium alloy components, and the temperature requirements for different grades of titanium alloys are essential to ensure optimal mechanical properties and microstructure. Titanium production companies must adhere to these forging temperature guidelines to produce high-quality parts that meet industry standards.

TA7

The α+β phase transition temperature of this alloy is 930–970°C, and the β phase transition temperature is 1040–1090°C. The forging temperature range for ingot breakdown is 1180–900°C, with an allowable deformation rate of 30–50%.

TA13

The β phase transition temperature of this alloy is 895±10°C. The forging temperature range for ingot breakdown is 1050–750°C, the preform temperature is 950–700°C, and the hammer forging temperature is 880–700°C.

TC4

This is a commonly used titanium alloy, with an α+β phase transition temperature of 980–1010°C. The forging temperature range for ingot breakdown is 1200–850°C, the preform temperature is 1000–800°C, and the hammer forging temperature is 980–800°C.

TC6

The α+β phase transition temperature of this alloy is 980±20°C. The forging temperature range for ingot breakdown is 1150–850°C, the preform temperature is 1050–800°C, and the hammer forging temperature is 950–800°C.

TC11

The α+β phase transition temperature of this alloy is 1000±20°C. The forging temperature range for ingot breakdown is 1200–900°C, the preform temperature is 980–800°C, and the hammer forging temperature is 980–850°C.

TB6

This is a near-β titanium alloy, with an α+β phase transition temperature of 800±15°C. The forging temperature range for ingot breakdown is 1150–850°C, the preform temperature is 840–700°C, and the hammer forging temperature is 800–680°C.

When forging different grades of custom titanium products, factors such as ingot preparation, heating, forging process, heat treatment, machining, grinding, ingot number management, ultrasonic flaw detection, sawing, and sampling must be taken into account. Additionally, the forging process performance of titanium alloys is also affected by alloying elements and impurities, so it is essential to strictly control the chemical composition and impurity content.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский