Thank you for your

attention on Yesheng !

High-Temperature Titanium Alloys and Various Types of Titanium Alloys: Classification and Properties

High-Temperature Titanium Alloys

The world's first high-temperature titanium alloy successfully developed was Ti-6Al-4V, with a service temperature of 300-350°C. Subsequently, alloys with a service temperature of up to 400°C, such as IMI550 and BT3-1, were developed, followed by alloys like IMI679, IMI685, Ti-6246, and Ti-6242, which can operate at 450-500°C. Recently, new high-temperature titanium alloys such as the UK's IMI829 and IMI834, the USA's Ti-1100, and Russia's BT18Y and BT36 have been successfully applied in aircraft engines. In recent years, international research has focused on developing high-temperature titanium alloys using rapid solidification/powder metallurgy techniques and fiber or particle reinforced composites, aiming to increase the operating temperature of titanium alloys to above 650°C. McDonnell Douglas in the USA successfully developed a high-purity, high-density titanium alloy using rapid solidification/powder metallurgy technology, which retains its strength at 760°C, comparable to current titanium alloys at room temperature.

Titanium Alloys Based on Titanium-Aluminum Compounds

Compared to conventional titanium alloys, titanium alloys based on titanium-aluminum compounds such as Ti3Al (α2) and TiAl (γ) have advantages including excellent high-temperature performance (service temperatures of 816°C and 982°C, respectively), strong oxidation resistance, good creep resistance, and low weight (density is only half that of nickel-based superalloys). These advantages make them competitive materials for future aerospace engines and aircraft structural components. Currently, two Ti3Al-based titanium alloys, Ti-21Nb-14Al and Ti-24Al-14Nb-#v-0.5Mo, are being produced in bulk in the USA. Other recently developed Ti3Al-based titanium alloys include Ti-24Al-11Nb, Ti-25Al-17Nb-1Mo, and Ti-25Al-10Nb-3V-1Mo. The focus for TiAl (γ)-based titanium alloys is on compositions in the range of TAl-(1-10)M (at.%), where M represents at least one element from V, Cr, Mn, Nb, Mn, Mo, and W. Recently, TiAl3-based titanium alloys, such as Ti-65Al-10Ni, have begun to attract attention.

High-Strength, High-Toughness β-Type Titanium Alloys

The earliest β-type titanium alloy was B120VCA (Ti-13V-11Cr-3Al), developed by Crucible Company in the USA in the mid-1950s. β-type titanium alloys have good hot and cold workability, are easy to forge, roll, and weld, and can achieve high mechanical properties and good environmental resistance through solution-aging treatment, with an excellent combination of strength and fracture toughness. Representative new high-strength, high-toughness β-type titanium alloys include:

Ti1023 (Ti-10V-2Fe-#Al): Comparable to the commonly used high-strength structural steel 30CrMnSiA in aircraft structural components, with excellent forging properties.

Ti153 (Ti-15V-3Cr-3Al-3Sn): Has better cold workability than commercially pure titanium, with room temperature tensile strength exceeding 1000 MPa after aging.

β21S (Ti-15Mo-3Al-2.7Nb-0.2Si): Developed by the Timet division of the Titanium Metals Corporation in the USA, this new ultra-high-strength titanium alloy has excellent oxidation resistance, outstanding hot and cold workability, and can be made into foils as thin as 0.064 mm.

SP-700 (Ti-4.5Al-3V-2Mo-2Fe): Developed by NKK in Japan, this alloy has high strength and superplastic elongation of up to 2000%, with a superplastic forming temperature 140°C lower than Ti-6Al-4V, making it a potential replacement for Ti-6Al-4V in superplastic forming-diffusion bonding (SPF/DB) technology for various aerospace components.

BT-22 (Ti-5V-5Mo-1Cr-5Al): Developed in Russia, with a tensile strength exceeding 1105 MPa.

Flame-Resistant Titanium Alloys

Conventional titanium alloys have a tendency to combust under specific conditions, which significantly limits their applications. To address this issue, various countries have conducted research on flame-resistant titanium alloys and achieved certain breakthroughs. Alloy C, also known as Ti-50V-35Cr-15Cr (mass fraction), is a flame-resistant titanium alloy developed in China that is insensitive to sustained burning and is used in the F119 engine. BTT-1 and BTT-3 are flame-resistant titanium alloys developed in Russia, both Ti-Cu-Al based, with excellent hot deformation processing performance, making them suitable for manufacturing complex parts.

Medical Titanium Alloys

Titanium is non-toxic, lightweight, strong, and has excellent biocompatibility, making it an ideal material for medical applications such as implants. Currently, the widely used alloy in the medical field is still Ti-6Al-4V ELI, but it can release trace amounts of vanadium and aluminum ions, reducing its cell compatibility and potentially causing harm to the human body. This issue has long been a concern in the medical community. The USA started developing aluminum-free, vanadium-free, biocompatible titanium alloys for orthopedic surgery in the mid-1980s. Japan, the UK, and other countries have also conducted extensive research and made some new advancements. For example, Japan has developed a series of α+β titanium alloys with excellent biocompatibility, including Ti-15Zr-4Nb-4Ta-0.2Pd, Ti-15Zr-4Nb-4Ta-0.2Pd-0.20~0.05N, Ti-15Sn-4Nb-2Ta-0.2Pd, and Ti-15Sn-4Nb-2Ta-0.2Pd-0.20, which have superior corrosion strength, fatigue strength, and corrosion resistance compared to Ti-6Al-4V ELI. Compared to α+β titanium alloys, β titanium alloys have higher strength, better notch performance, and toughness, making them more suitable for implants. In the USA, five β titanium alloys have been recommended for medical applications: TMZFTM (Ti-12Mo-^Zr-2Fe), Ti-13Nb-13Zr, Timetal 21SRx (Ti-15Mo-2.5Nb-0.2Si), Tiadyne 1610 (Ti-16Nb-9.5Hf), and Ti-15Mo. It is estimated that in the near future, these high-strength, low-elastic-modulus, and excellent-formability and corrosion-resistant β titanium alloys are likely to replace the widely used Ti-6Al-4V ELI alloy in the medical field.

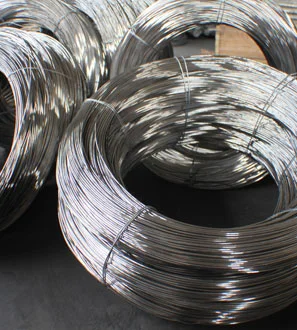

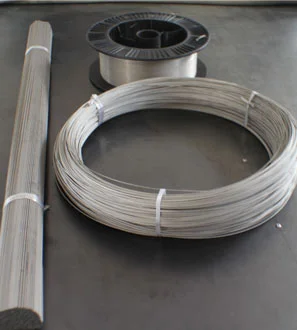

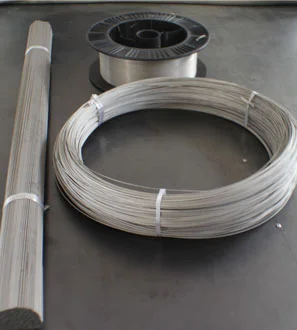

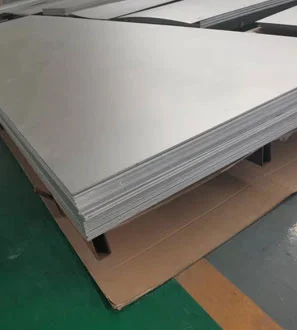

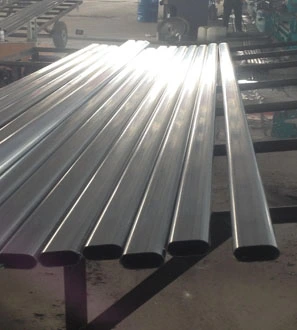

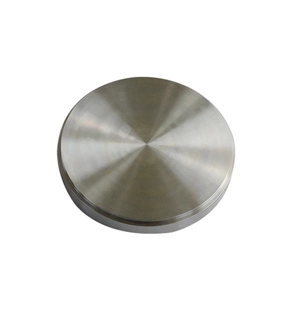

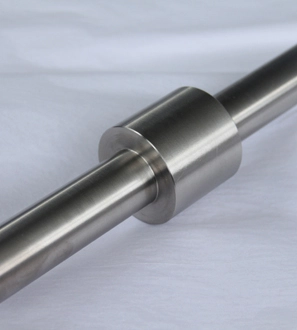

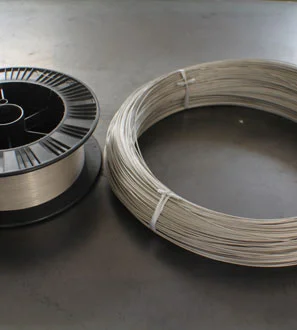

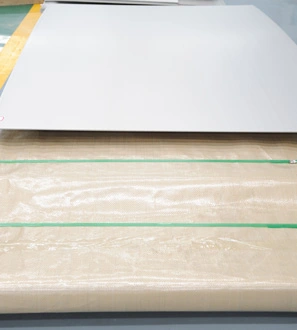

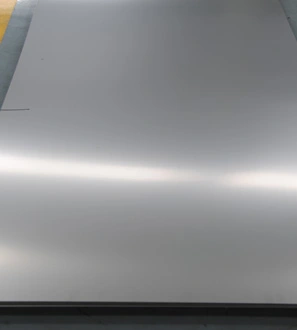

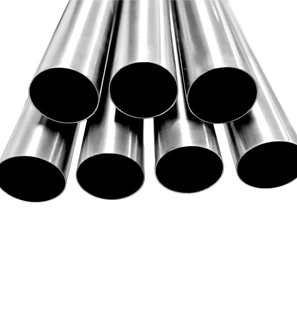

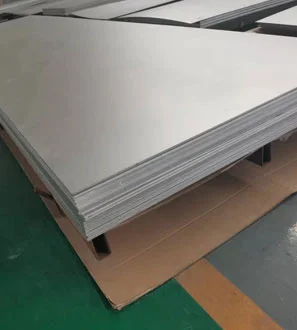

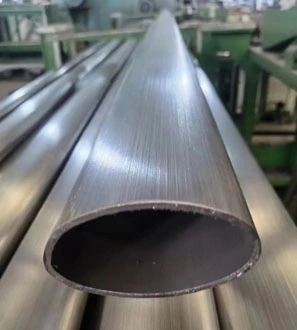

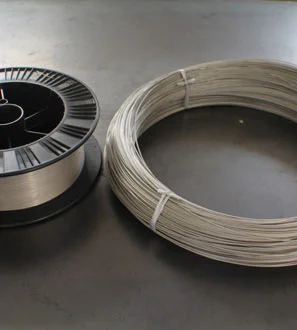

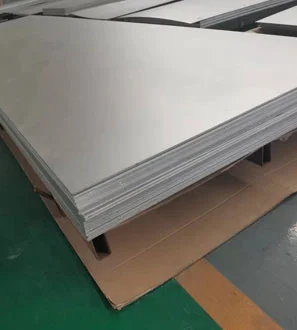

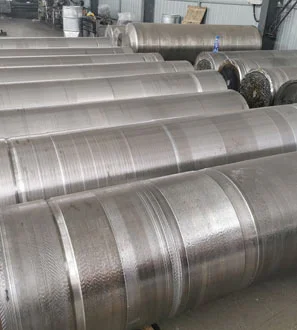

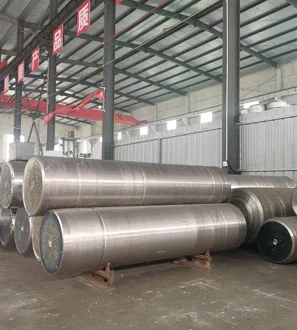

Established in 2007, Baoji Yesheng Titanium Industry Co., Ltd. is a high-tech company that integrates the production, processing, and sales of titanium and titanium alloys, nickel, zirconium, and other non-ferrous elements. It is situated in China's "Titanium Valley"-Baoji. Plates, bars, wires, tubes, standard components, forgings, equipment, and titanium and titanium alloys are the primary products. Nickel, zirconium, and alloys are also important.Welcome your consultation.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский