Thank you for your

attention on Yesheng !

Types and Uses of Titanium Alloys

Titanium alloys are composed of titanium as the base element with the addition of other alloying elements. They can be categorized into structural titanium alloys and heat-resistant titanium alloys, or more specifically into α-type, β-type, and α+β-type titanium alloys.

1. Development History of Titanium Alloys

Titanium emerged as a crucial structural metal in the 1950s. Recognizing the importance of titanium alloy materials, many countries around the world began researching and developing them, leading to practical applications.

The first practical titanium alloy, Ti-6Al-4V, was developed in the United States in 1954. It became a cornerstone of the titanium alloy industry due to its excellent heat resistance, strength, plasticity, toughness, formability, weldability, corrosion resistance, and biocompatibility. This alloy accounts for 75%-85% of all titanium alloys used, and many other titanium alloys are modifications of it.

The industrial production of titanium began in 1948. During the 1950s and 60s, efforts were focused on developing high-temperature titanium alloys for aerospace engines and structural titanium alloys for airframes. The 1970s saw the development of corrosion-resistant titanium alloys, and since the 1980s, further advancements have been made in corrosion-resistant and high-strength titanium alloys. The operating temperature of heat-resistant titanium alloys has increased from 400°C in the 1950s to 600-650°C in the 1990s, expanding their use from the cold end of engines (fans and compressors) to the hot end (turbines). Structural titanium alloys have evolved towards high strength, high plasticity, high toughness, high modulus, and high damage tolerance.

Since the 1970s, shape memory alloys such as Ti-Ni, Ti-Ni-Fe, and Ti-Ni-Nb have been developed and widely used in engineering. In China, research on titanium and titanium alloys began in 1956, and the industrial production of titanium materials and the development of the TB2 alloy started in the mid-1960s.

2. Major Classifications of Titanium Alloys

Titanium exists in two allotropic forms. Titanium alloys are classified based on these forms, with a melting point of 1668°C. Below 882°C, titanium has a hexagonal close-packed crystal structure, called α-titanium. Above 882°C, it has a body-centered cubic structure, called β-titanium. By adding suitable alloying elements, the phase transformation temperature and phase content can be adjusted to create different titanium alloy structures.

At room temperature, titanium alloys have three types of matrix structures, resulting in three types of titanium alloys: α alloys, (α+β) alloys, and β alloys. In China, they are denoted by TA, TC, and TB respectively.

α Titanium Alloys: Composed of a single-phase α solid solution, these alloys have stable structures at both general and higher application temperatures. They offer higher wear resistance and oxidation resistance compared to pure titanium. They maintain their strength and creep resistance at 500-600°C, but they cannot be strengthened by heat treatment and have low room temperature strength.

β Titanium Alloys: These are single-phase alloys composed of a β solid solution. They have high strength without heat treatment, and further strengthening can be achieved through quenching and aging, resulting in room temperature strengths of 1372-1666 MPa. However, they have poor thermal stability and are not suitable for high-temperature applications.

α+β Titanium Alloys: These are dual-phase alloys with good comprehensive properties, stable structure, good toughness, plasticity, and high-temperature deformation performance. They can be processed by hot pressure, quenched, and aged for alloy strengthening. The strength after heat treatment is about 50%-100% higher than the annealed state, with good high-temperature strength for long-term use at 400-500°C, though their thermal stability is slightly lower than α titanium alloys.

Among the three, α titanium alloys and α+β titanium alloys are the most commonly used. α titanium alloys offer the best machinability, followed by α+β alloys, with β alloys being the least machinable.

Titanium alloys can also be classified by application into heat-resistant alloys, high-strength alloys, corrosion-resistant alloys (such as titanium-molybdenum and titanium-palladium alloys), low-temperature alloys, and special functional alloys (such as titanium-iron hydrogen storage materials and titanium-nickel memory alloys).

The phase composition and microstructure of titanium alloys can be varied by adjusting the heat treatment process:

Fine equiaxed structures offer good plasticity, thermal stability, and fatigue strength.

Acicular structures provide high endurance strength, creep strength, and fracture toughness.

Mixed equiaxed and acicular structures offer good overall performance.

3. Characteristics of Titanium Alloys

Titanium alloys are ideal aerospace structural materials due to their low density, high specific strength, good corrosion resistance, high heat resistance, and favorable processing characteristics. They are widely used across various fields.

Titanium is a relatively new metal, and its properties are influenced by the content of impurities like carbon, nitrogen, hydrogen, and oxygen. The purest form, iodide titanium, contains less than 0.1% impurities, resulting in low strength but high plasticity. Industrial pure titanium with 99.5% purity has a density of 4.5 g/cm³, a melting point of 1725°C, and a hardness of HB195.

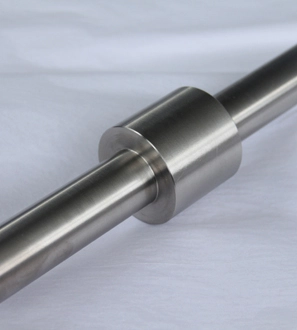

High Strength: Titanium alloys have a density of around 4.51 g/cm³, only 60% of that of steel. Pure titanium has a strength similar to that of ordinary steel, and some high-strength titanium alloys surpass many alloy steels in strength. Consequently, titanium alloys have a much higher specific strength (strength/density) than other metallic structural materials, enabling the production of components with high unit strength, good rigidity, and light weight. Titanium alloys are used in aircraft engine components, frames, skins, fasteners, and landing gear.

High Heat Resistance: Titanium alloys can operate at temperatures several hundred degrees higher than aluminum alloys and maintain their required strength at medium temperatures, working for extended periods at 450-500°C. They retain high specific strength between 150-500°C, whereas aluminum alloys' specific strength drops significantly at 150°C. Titanium alloys can work at temperatures up to 500°C, compared to under 200°C for aluminum alloys.

Good Corrosion Resistance: In humid atmospheres and seawater, titanium alloys outperform stainless steel in corrosion resistance. They resist pitting, acid corrosion, and stress corrosion, and have excellent resistance to bases, chlorides, organic substances, nitric acid, and sulfuric acid. However, they are less resistant to reducing oxygen and chromate media.

Good Low-Temperature Performance: Titanium alloys retain their mechanical properties at low and ultra-low temperatures. Alloys with extremely low levels of interstitial elements can maintain some plasticity even at -253°C, making titanium alloys important low-temperature structural materials.

High Chemical Activity: Titanium has high chemical reactivity, reacting strongly with atmospheric O, N, H, CO, CO2, water vapor, and ammonia. When the carbon content exceeds 0.2%, hard TiC forms in the alloy. At high temperatures, it forms TiN with nitrogen, and above 600°C, it absorbs oxygen, forming a hard surface layer. Increased hydrogen content leads to embrittlement. The depth of the hardened brittle layer due to gas absorption can reach 0.1-0.15 mm, with a hardness increase of 20%-30%. Titanium also has high chemical affinity, easily adhering to friction surfaces.

Low Thermal Conductivity and Elastic Modulus: Titanium's thermal conductivity is 15.24 W/(m·K), which is about one-fourth that of nickel, one-fifth that of iron, and one-fourteenth that of aluminum. The thermal conductivity of various titanium alloys is about 50% lower than that of pure titanium. Titanium alloys have an elastic modulus about half that of steel, making them less rigid and prone to deformation. This, along with significant spring-back during machining, leads to high friction and wear on cutting tools.

4. Advances in Titanium Alloys

The superior properties of titanium, titanium alloys, and titanium compounds have created a pressing need for their use. However, their high production costs have limited their application. Despite the superior performance of titanium alloy components, they are far from widespread use. The reasons include their high cost, poor formability, and challenging welding characteristics. The price of titanium alloys is significantly higher than other metals, both in terms of initial smelting and subsequent processing.

In recent years, with the development of near-net shape technology for titanium alloys and modern welding techniques such as electron beam welding, plasma arc welding, and laser welding, the issues of forming and welding titanium alloys are no longer the primary barriers to their application. Countries worldwide are now developing low-cost, high-performance new titanium alloys, striving to introduce titanium alloys into civilian industries with great market potential. Recent advancements in titanium alloy materials research, both domestically and internationally, can be summarized as follows:

High-Temperature Titanium Alloys

In recent years, foreign researchers have focused on developing high-temperature titanium alloys using rapid solidification/powder metallurgy techniques and fiber or particle-reinforced composites. This has increased the operational temperature of titanium alloys to above 650°C. McDonnell Douglas in the United States successfully developed a high-purity, high-density titanium alloy using rapid solidification/powder metallurgy technology, which has a strength at 760°C comparable to the strength of current titanium alloys at room temperature.

Titanium Aluminide-Based Titanium Alloys

Compared to general titanium alloys, titanium aluminide-based intermetallic compounds, such as Ti3Al (α2) and TiAl (γ), have significant advantages in high-temperature performance (maximum operating temperatures of 816°C and 982°C, respectively), oxidation resistance, creep resistance, and lightweight properties (density is only half that of nickel-based superalloys). These advantages make them highly competitive materials for future aerospace engine and aircraft structural components.

High-Strength, High-Toughness β-Type Titanium Alloys

The first β-type titanium alloy, B120VCA (Ti-13V-11Cr-3Al), was developed by the Crucible company in the United States in the mid-1950s. β-type titanium alloys have good hot and cold workability, are easy to forge, roll, and weld, and can achieve high mechanical properties, good environmental resistance, and a good balance of strength and fracture toughness through solution-aging treatment. The most representative new high-strength, high-toughness β-type titanium alloys include:

Ti1023 (Ti-10V-2Fe-#Al): This alloy is comparable in performance to 30CrMnSiA high-strength structural steel commonly used in aircraft structural components and has excellent forging properties.

Ti153 (Ti-15V-3Cr-3Al-3Sn): This alloy has better cold working properties than commercially pure titanium, with an aged room temperature tensile strength exceeding 1000 MPa.

β21S (Ti-15Mo-3Al-2.7Nb-0.2Si): Developed by Timet, a division of Titanium Metals Corporation in the U.S., this new oxidation-resistant, ultra-high-strength titanium alloy has excellent oxidation resistance, and hot and cold workability, and can be made into foils as thin as 0.064 mm.

Flame-Resistant Titanium Alloys

Conventional titanium alloys have a tendency to burn under specific conditions, which greatly limits their application. To address this, various countries have researched flame-resistant titanium alloys and achieved certain breakthroughs. The U.S. developed Alloy C, a flame-resistant titanium alloy insensitive to sustained burning, which is used in the F119 engine. BTT-1 and BTT-3, developed by Russia, are flame-resistant titanium alloys in the Ti-Cu-Al system, which have excellent hot deformation processing properties and can be used to make complex parts.

Medical Titanium Alloys

Titanium is non-toxic, lightweight, strong, and has excellent biocompatibility, making it an ideal material for medical applications, such as implants in the human body. Currently, Ti-6Al-4V ELI alloy is widely used in the medical field. However, this alloy can release trace amounts of vanadium and aluminum ions, reducing its cellular compatibility and potentially harming the human body. This issue has long been a concern in the medical community. As early as the mid-1980s, the U.S. began developing aluminum-free, vanadium-free, biocompatible titanium alloys for use in orthopedic surgery. Japan, the UK, and other countries have also conducted extensive research in this area and achieved some new progress. It is estimated that in the near future, high-strength, low-modulus, and corrosion-resistant titanium alloys will likely replace the widely used Ti-6Al-4V ELI alloy in the medical field.

5、Major Applications of Titanium Alloys

Titanium alloys are a new important structural material used in the aerospace industry, with density, strength, and operating temperature between those of aluminum and steel. They have high specific strength and excellent seawater corrosion resistance and ultra-low temperature performance. Titanium alloys are mainly used to manufacture compressor components for aircraft engines, as well as structural components for rockets, missiles, and high-speed aircraft. Since the mid-1960s, titanium and its alloys have been applied in general industry, used to make electrodes in the electrolysis industry, condensers in power stations, heaters for petroleum refining and seawater desalination, and environmental pollution control devices. Titanium and its alloys have become a type of corrosion-resistant structural material and are also used to produce hydrogen storage materials and shape memory alloys.

Due to their light weight, high specific strength, and good corrosion resistance, titanium alloys are widely used in the aviation industry, especially in engine systems. Using titanium alloys to manufacture engine components offers numerous benefits.

The low density of titanium alloys can reduce the inertial mass of moving parts, thereby reducing friction and improving fuel efficiency. Titanium valve springs can increase free vibration and reduce oscillation.

Choosing titanium alloys can reduce the load stress on related components and decrease the size of parts, thereby reducing the weight of the engine and the entire aircraft. The reduction in component inertia mass reduces vibration and noise, improves engine performance, and increases engine speed and output power. The application of titanium alloys in other components can enhance comfort and aesthetics. Titanium alloys play an invaluable role in energy conservation and consumption reduction.

Titanium alloys have high strength, low density, good mechanical properties, toughness, and excellent corrosion resistance. However, their poor processability, difficulty in machining, and tendency to absorb impurities like hydrogen, oxygen, nitrogen, and carbon during hot processing, as well as poor wear resistance and complex production processes, present challenges. The need for advancements in the aerospace industry has led to the titanium industry growing at an average annual rate of about 8%. Currently, the annual production of titanium alloy processed materials worldwide exceeds 40,000 tons, with nearly 30 grades of titanium alloys.

High-strength springs made from titanium alloys, which take advantage of their high strength and superb corrosion resistance, are now widely used in civilian applications such as mattresses. By incorporating titanium alloy technology in mattress springs, new titanium alloy springs can conform to body contours, providing unique support that transitions from soft to firm, offering deep sleep comfort. Furthermore, with twice high-temperature shaping treatment, the elasticity and resilience of the springs are significantly improved, enhancing durability.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский