Thank you for your

attention on Yesheng !

Physical Properties of Ti6Al4V Titanium Alloy

Ti6Al4V titanium alloy is a commonly used titanium alloy material known for its excellent mechanical properties and corrosion resistance. It is widely used in aerospace, automotive manufacturing, medical devices, and other fields. The main characteristics of Ti6Al4V titanium alloy include excellent comprehensive performance and good processing properties. Ti6Al4V titanium alloy features medium room temperature strength and high-temperature strength, good creep resistance and thermal stability, high fatigue resistance and crack growth resistance in seawater, satisfactory fracture toughness, and resistance to hot salt stress corrosion, making it suitable for manufacturing various parts operating within a wide temperature range of -196°C to 450°C, especially for components designed using damage tolerance principles. Ti6Al4V titanium alloy also has excellent process plasticity and superplasticity, making it suitable for various pressure processing methods, welding, and machining.

The main semi-finished products of Ti6Al4V titanium alloy include bars, forgings, thick plates, thin plates, profiles, and wires. This alloy is usually used in the annealed state, but it can be strengthened to some extent through solution aging treatment; however, the quenching section generally does not exceed 25mm. The alloy possesses good process plasticity and superplasticity, suitable for various pressure processing forming methods. Additionally, it can be welded and machined using various methods.

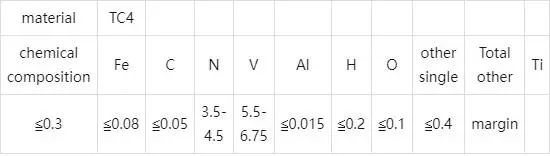

Chemical Composition of Ti6Al4V Titanium Alloy (in %)

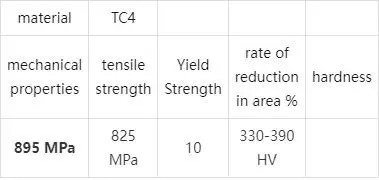

Mechanical Properties of Ti6Al4V Titanium Alloy

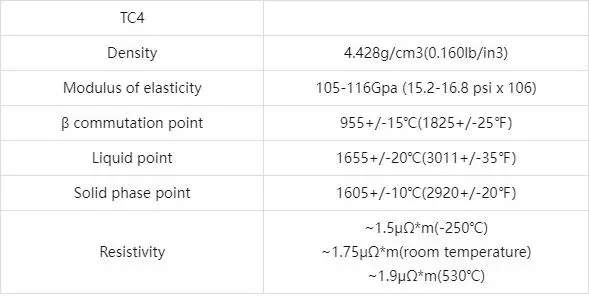

Physical Properties of Ti6Al4V Titanium Alloy

Melting and Casting Process of Ti6Al4V Titanium Alloy

The ingot melting process should be carried out through at least two vacuum consumable electrode arc furnace meltings. Raw materials for engine rotor parts should undergo three meltings. Alloy element V should be added in the form of Al-V intermediate alloy. The use of tungsten inert gas welding to weld the consumable electrode is prohibited; instead, argon gas shielded plasma welding should be used.

Oxidation Resistance of Ti6Al4V Titanium Alloy

As the heating temperature increases, the oxidation film formed on Ti6Al4V titanium alloy thickens, but its protective properties deteriorate. When the alloy is heated at 700°C for 2 hours, the thickness of the oxidation film reaches 25μm. When heated above 800°C, the formed oxidation layer becomes more sparse. After heating the alloy at 1000°C for 1 hour, the thickness of the oxidation layer reaches 0.65mm.

Welding Performance of Ti6Al4V Titanium Alloy

Ti6Al4V alloy can be welded using various methods such as argon arc welding, spot welding, brazing, electron beam welding, and plasma welding, with the strength of the welded joints being similar to the base metal.

Stress relief annealing after welding Ti6Al4V alloy, performed at 550-650°C, can eliminate 70%-80% of welding stress. For welding of sheet metal parts, stress relief annealing is best carried out in a vacuum furnace or protective atmosphere furnace.

Ti6Al4V alloy has excellent diffusion bonding properties, and the diffusion bonding process must be carried out in a vacuum environment. Typical diffusion bonding process parameters include a heating temperature of 820-1040°C, a pressing pressure of 35-70MPa, and a holding time of 0.5-6 hours.

Heat Treatment Process of Ti6Al4V Titanium Alloy

Heat treatment is an indispensable part of titanium alloy processing, improving mechanical properties, strength, hardness, and corrosion resistance.

Typical Heat Treatment Processes:

1.Annealing:

Sheet: Anneal at 700-850°C for 0.5-2 hours, then air cool.

Bar and forgings: Anneal at 700-800°C for 1-2 hours, then air cool.

2.Vacuum Annealing:

Anneal at 700-800°C for 0.5-2 hours, then cool the furnace to below 200°C, allowing for air cooling after removal. The absolute pressure in the furnace should not exceed 0.09Pa.

3.Solution Treatment:

Perform solution treatment at 910-940°C for 0.5-2 hours, followed by water quenching.

4.Aging:

Age at 520-550°C for 2-4 hours, then air cool.

5.Stress Relief Annealing:

Complete stress relief annealing: Anneal at 600-650°C for 1-4 hours, then air cool.

Incomplete stress relief annealing: Anneal at 500-600°C for 0.5-3 hours, then air cool.

Stress relief annealing can be performed in an air furnace or a vacuum furnace.

Surface Treatment Processes for Ti6Al4V Titanium Alloy

1.Shot Peening:

To enhance fatigue resistance, shot peening treatment can be performed using steel shots with diameters of 2-5mm, generating compressive stress of about 785MPa and achieving a surface strengthening depth of about 200μm, significantly improving fatigue resistance.

2.Wear Resistance Enhancement:

For improving wear resistance, difficult-to-melt particle coatings such as tungsten carbide or chromium carbide can be applied to easily worn areas, such as the damping surfaces of fan blades, using plasma or explosive spraying methods. This method can also be used to repair worn parts.

3.Friction and Adhesion Prevention:

To prevent galling and adhesion during operation, anodizing, chrome plating, chemical nickel plating, or nitriding treatments can be performed on parts with frictional contact and threaded combinations.

Applications of Ti6Al4V Titanium Alloy

Ti6Al4V titanium alloy, composed of titanium, aluminum, zinc, and iron, is known for its high strength, low density, excellent corrosion resistance, and good toughness, making it widely applicable in many fields.

Aerospace:

Ti6Al4V titanium alloy is widely used in the aerospace field for manufacturing components of aircraft, missiles, and rockets. Its high strength and low density make aircraft lighter, improving fuel efficiency, while its excellent corrosion resistance makes it suitable for harsh air environments.

Medical Devices:

Ti6Al4V titanium alloy is used for making artificial joints, dental restoration materials, implants, and other medical devices. It has good biocompatibility, reducing the risk of rejection, and its excellent corrosion resistance and mechanical properties meet the requirements of medical devices.

Chemical Industry:

Ti6Al4V titanium alloy is extensively used in the chemical industry for reactors, heat exchangers, storage tanks, and other equipment. Its corrosion resistance makes it suitable for withstanding various acids, alkalis, and chemical substances, ensuring the safe operation of equipment.

Automotive Manufacturing:

Ti6Al4V titanium alloy is used in automotive manufacturing for engine components, chassis parts, and other components. Its high strength and low density reduce vehicle weight, improving performance, while its heat and wear resistance meet the demands of complex working conditions.

Sporting Goods:

Ti6Al4V titanium alloy is widely used in sporting goods such as golf clubs, bicycle frames, and more. Its high strength and excellent elasticity provide better striking force and shock absorption, while its corrosion resistance makes it suitable for outdoor use.

In summary, Ti6Al4V titanium alloy's excellent properties make it highly applicable in aerospace, medical devices, chemical industry, automotive manufacturing, sporting goods, and other fields.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  русский

русский

.jpg)